A Horizontal Taping Machine Automatically Adjusting Taping Tension

An automatic adjustment and taping machine technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of being consistent forever, the shielding layer cannot be evenly wound around the outside of the wire, and the tension of the tape cannot be guaranteed. To achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

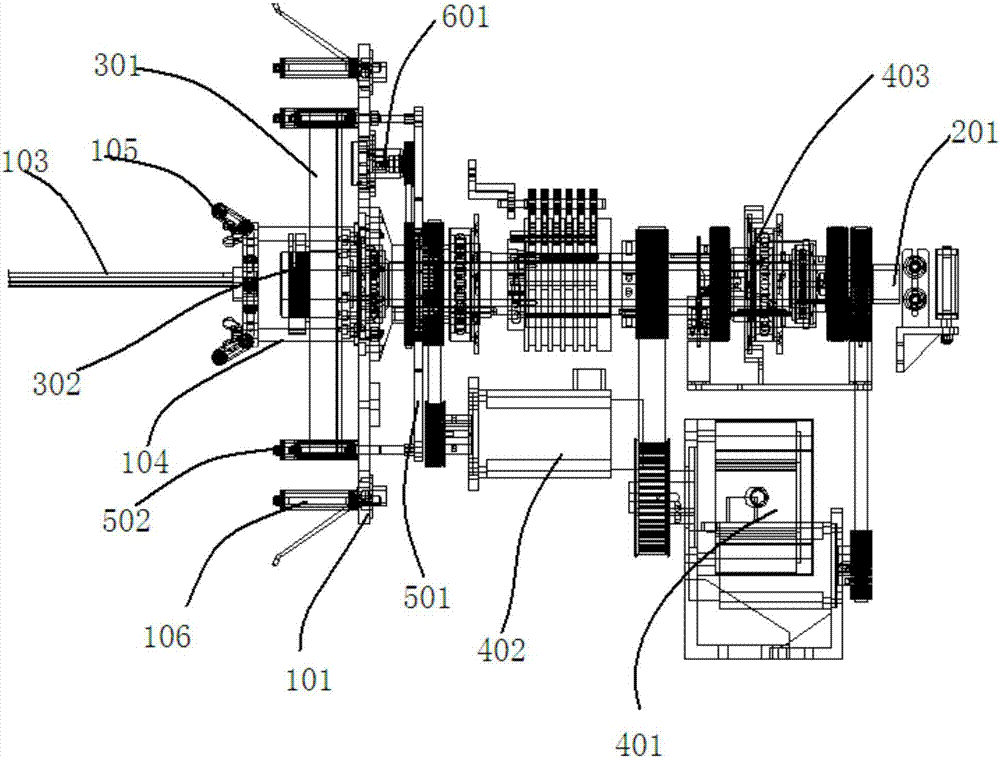

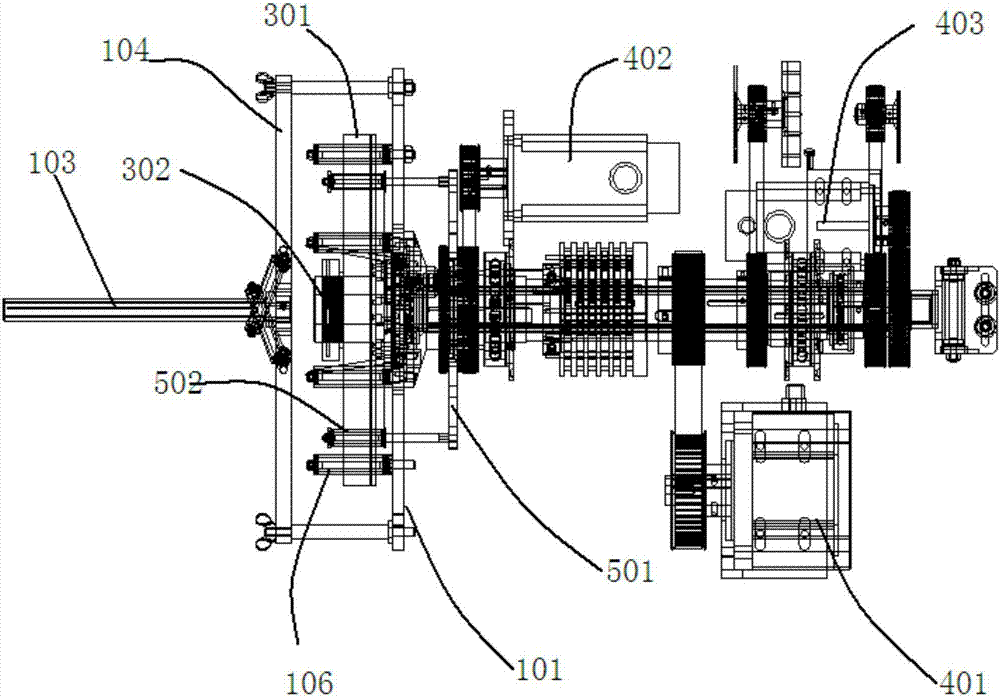

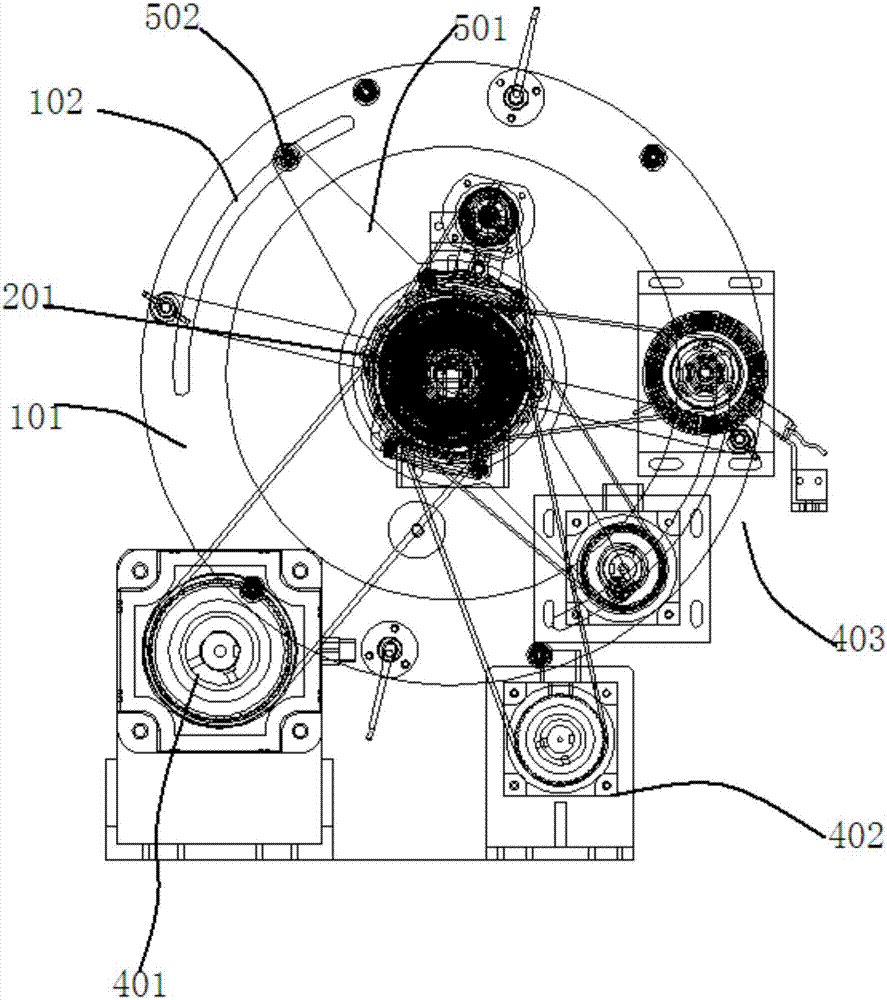

[0028] refer to Figure 1-3 As shown, this embodiment discloses a horizontal taping machine that automatically adjusts the tension of the taping. The taping machine is a horizontal taping machine, and the device is arranged on the frame. The main structure includes:

[0029] A tape reel 101 , the tape reel 101 is driven to rotate by a main shaft 201 , a tape feed reel 301 is fixed on the tape reel 101 , and the tape feed reel 301 is fixed on the tape reel 101 by a nut 302 .

[0030] The above-mentioned main shaft 201 is driven by the first motor 401 to rotate, that is, the above-mentioned first motor 401 is the power source for the rotation of the tape reel 101, the above-mentioned main shaft 201 is a hollow shaft, and the electric wire is sent to the tape reel 101 by a free end of the main shaft 201 The end winding, that is, the above-mentioned taping reel 101 is arranged on the other free end of the above-mentioned main shaft 201 .

[0031] In order to adjust the tape tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com