Penetrating type connector combination

A connector combination and penetration technology, which is applied in the direction of connection, conductive connection, and parts of the connection device, can solve the problems of high defective product rate, poor contact, troublesome operation process, etc., and achieve high reliability and easy assembly. , the effect of improving connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

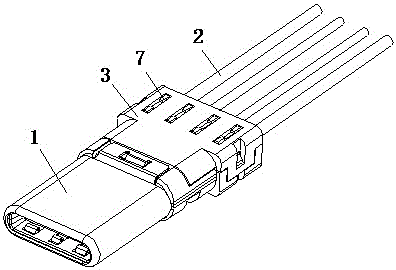

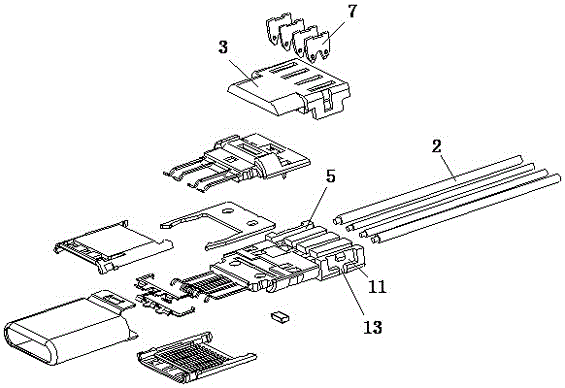

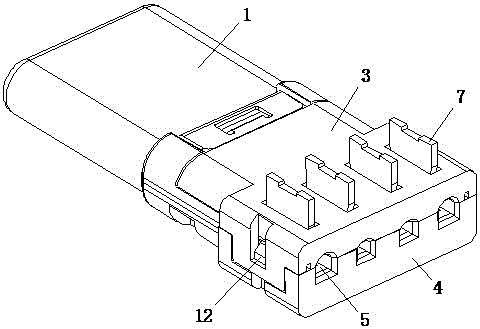

[0019] In this example, refer to figure 1 , figure 2 , image 3 and Figure 4 , the penetrating connector combination includes a main body and a cable, the cable has several independent core wires 2, the main body includes a connector 1, a conductive terminal and a base 4, and the connector 1 is fixed on the base 4 At the front end, a number of conductive terminals extend from the base 4 to the connector 1, and the cable is connected and fixed in the base 4 with the core wire 2 inside; 2, the wire groove 5, the width and depth of the wire groove 5 matches the core wire 2; the bottom of the wire groove 5 is provided with a connecting terminal 15, and the connecting terminal 15 is electrically connected to the conductive terminal; a The upper cover 3 has several penetration holes 6 in the upper cover 3, and the penetration holes 6 are aligned up and down with the wire groove 5; a conductive penetration sheet 7 is inserted downward from the penetration hole 6, and the penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com