Automatic track logistics electric brush apparatus

A brush device and track logistics technology, applied in the direction of circuits, collectors, electrical components, etc., can solve the problems of inflexible reset of copper brushes, large safety hazards, cumbersome installation, etc., to reduce the probability of power failure, reset ability and reset The effect of enhancing the effect and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

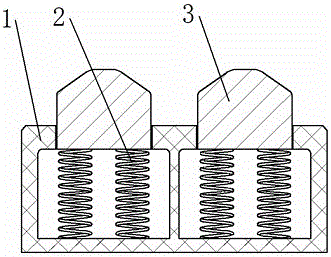

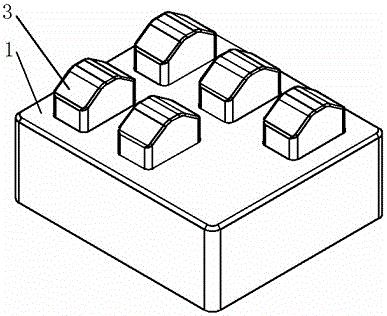

[0011] like Figure 1-2 As shown, the present invention is mainly made up of parts such as base 1, spring 2, copper brush 3, two springs 2 are installed on the bottom of copper brush 3, and the other end of spring 2 is in contact with base 1. The number of copper brushes 3 is 5, two as a group, installed side by side on the base 1, to ensure that the copper brushes are always in contact with the copper rails, to prevent power failure, divided into three groups and installed in the cavity in the base 1 , and can move up and down in base 1.

[0012] The spring 2 is symmetrically installed on the copper brush 3 to provide a uniform restoring force and ensure that the copper brush 3 and the base 1 maintain an assembly relationship in both natural elongation and compression states. When the top position of the copper brush 3 is the highest relative to the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com