Track marking robot

A robot and marking technology, applied in the field of robotics, can solve the problems of complicated preparation work, irregular fonts, uneven background color, etc., and achieve the effects of standardized daily management, high marking efficiency, and maximized economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

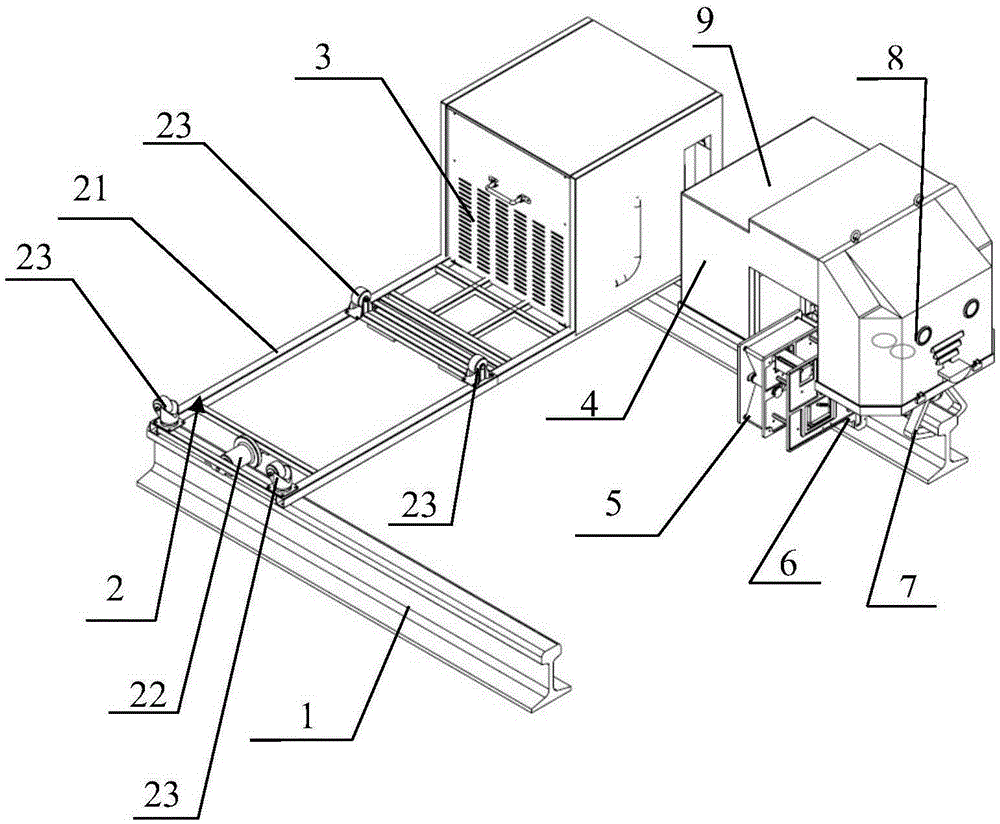

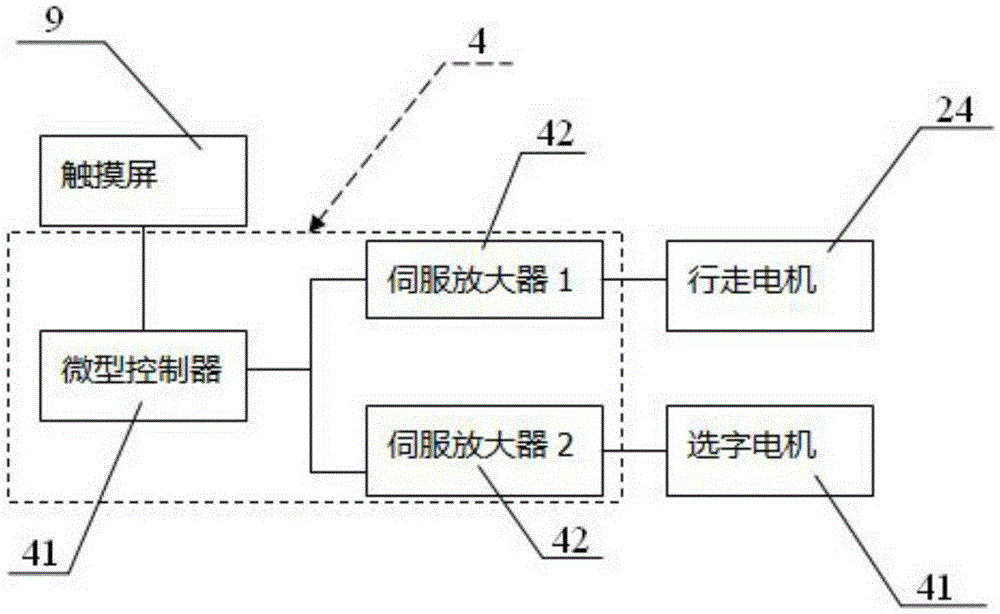

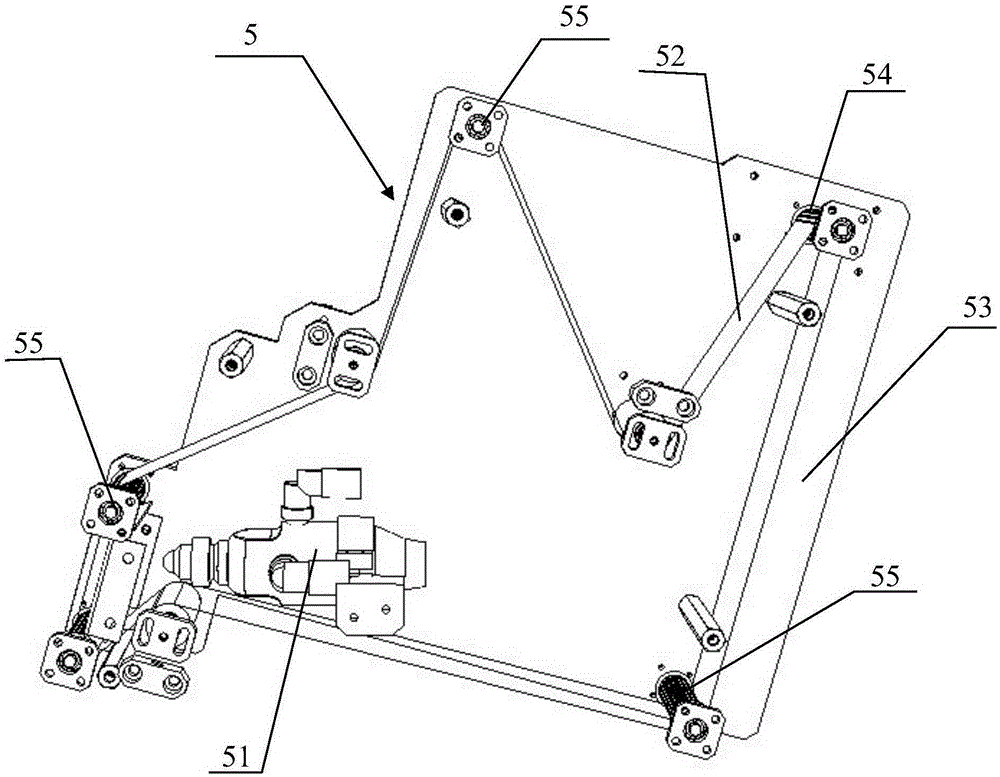

[0033] Such as figure 1 As shown, the track marking robot includes: a walking unit 2 , a power unit 3 , a control unit 4 , a printing unit 5 , a lighting unit 8 , and an operating unit 9 .

[0034] The walking unit 2 has a walking folding frame 21, and the walking folding frame 21 adopts a double caster design, and a rolling wheel 22 is respectively arranged on the base and the chassis, which are wear-resistant and non-slip. The shaft of the scroll wheel 22 is designed to be adjustable left and right, so as to facilitate the adjustment of the left and right deviation on the rail 1 caused by the installation error. Four universal casters 23 are installed on the chassis, and when stretched out, the universal casters 23 are placed upwards, which does not affect the movement of the power unit on the track. When folded, the universal casters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com