bearing ring with retaining flange

A technology of bearing rings and flanges, applied in the field of bearing rings, can solve problems such as cracks and achieve good thermal expansion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

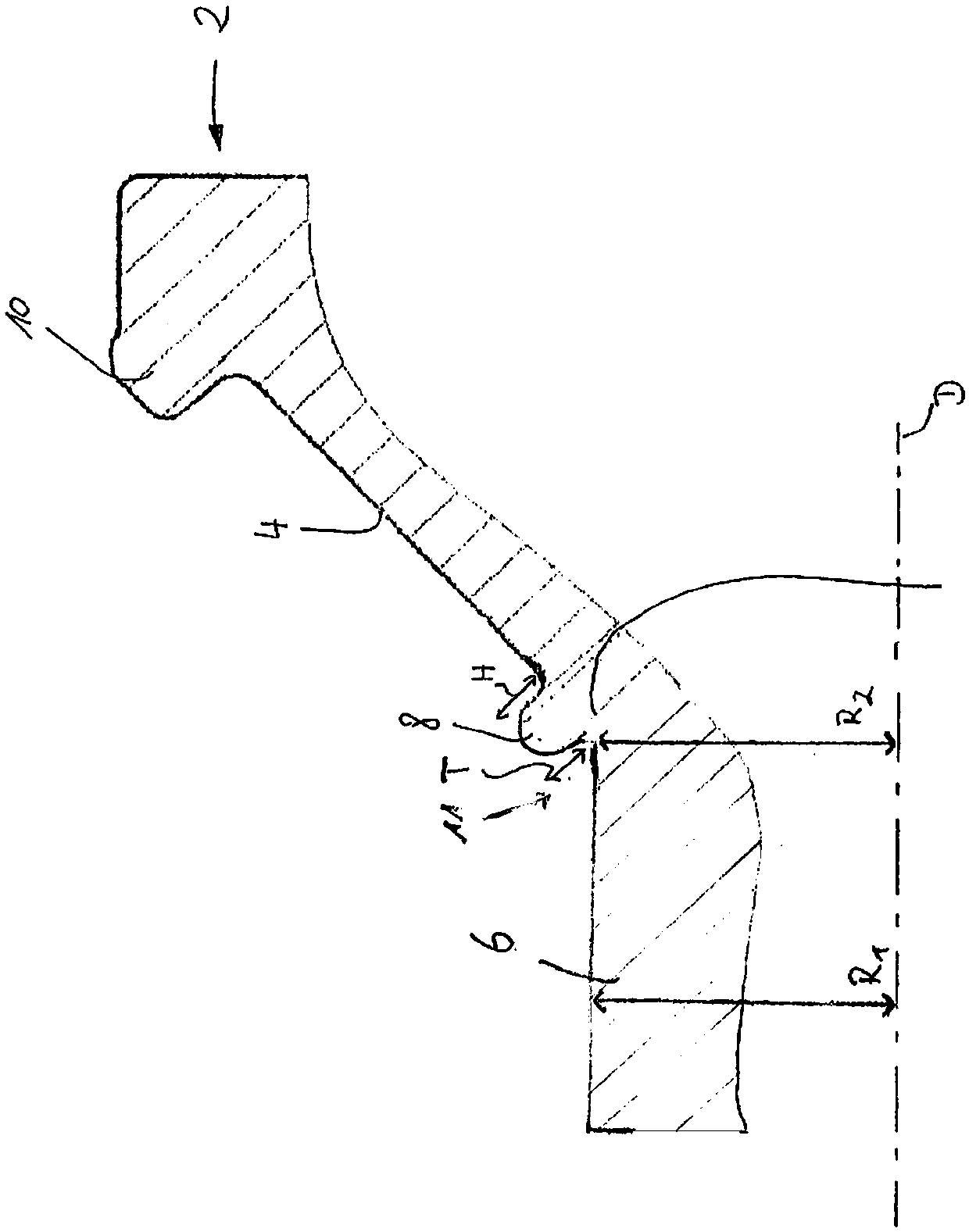

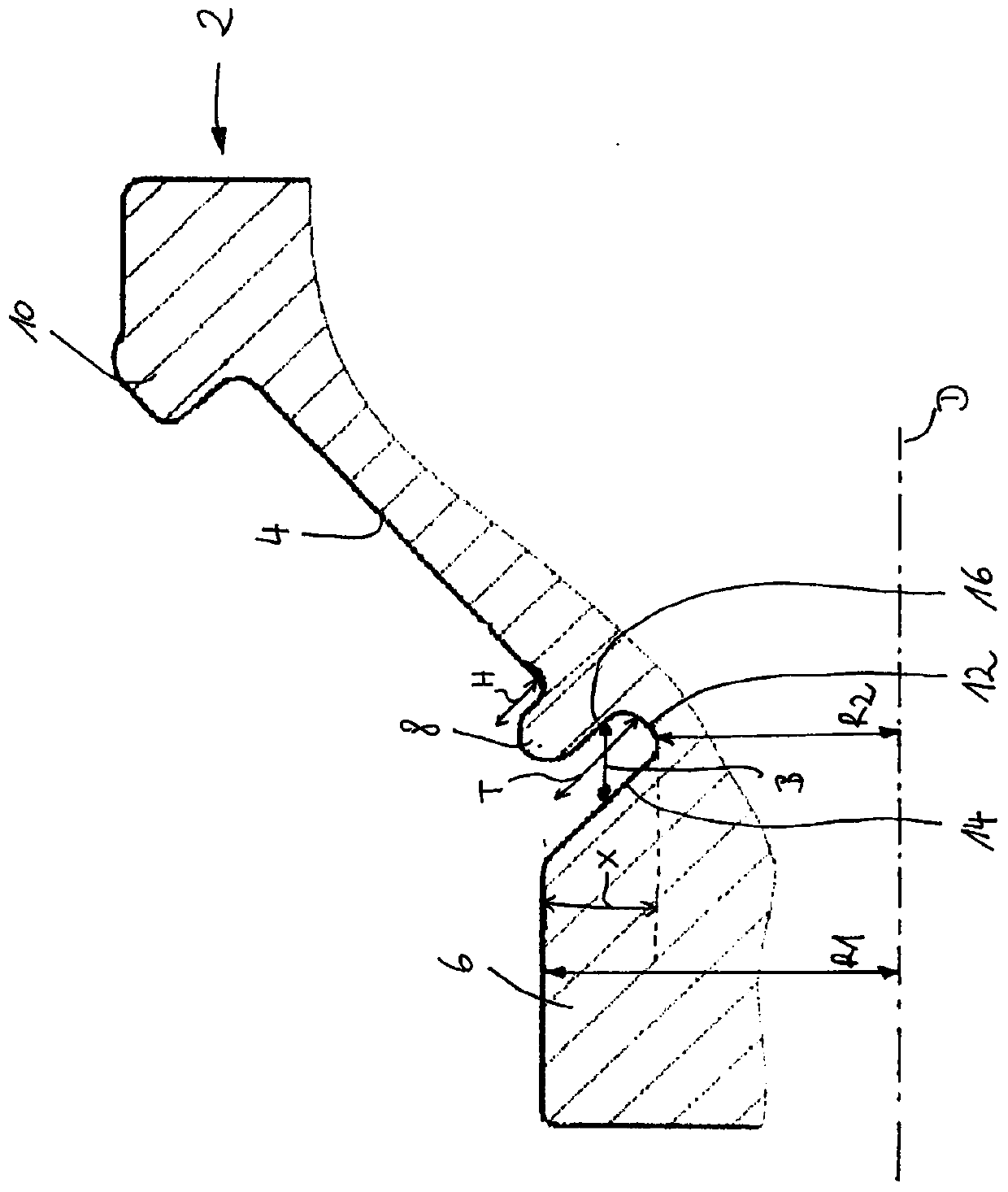

[0040] figure 1 A schematic cross-sectional view of a bearing ring 2 according to the invention is shown, which has a raceway surface 4 on which rolling elements (not shown) can be arranged. Furthermore, the bearing ring 2 has a guide flange 10 and a retaining flange 8 transitioning into the bearing ring shoulder 6 , wherein in particular the retaining flange 8 is higher than the raceway surface 4 of the bearing ring 2 by a height H. Here, the bearing ring shoulder 6 and the retaining flange 8 are the edge regions of the bearing ring 2 which do not need to be hardened, while the raceway surface 4 and the guide flange 10 are preferably induction hardened.

[0041] like figure 1 It is further shown that the retaining flange 8 is configured to be free-standing and has an open space 11 between the shoulder 6 and the retaining flange 8, which is preferably configured here as a groove 12, which is constructed as complete The groove has a depth T and a width B. Wherein, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com