A drill bit performance evaluation method and system

An evaluation method and drill bit technology, which is applied in the automatic control system of drilling, earthwork drilling, drilling equipment, etc., can solve the problems of large parameter gap, large error, and inability to accurately reflect the working performance, etc., and achieve the effect of accurate calculation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

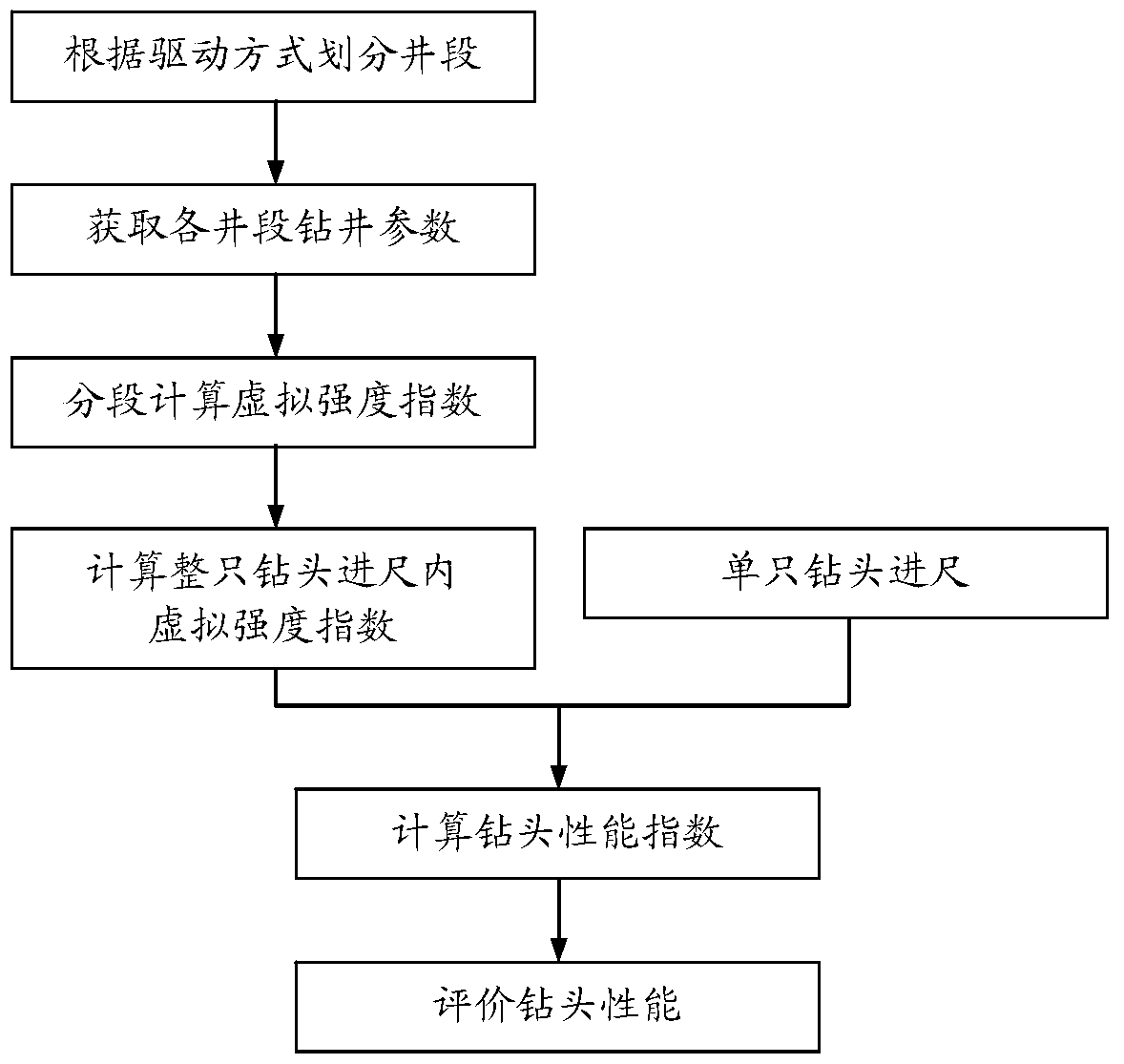

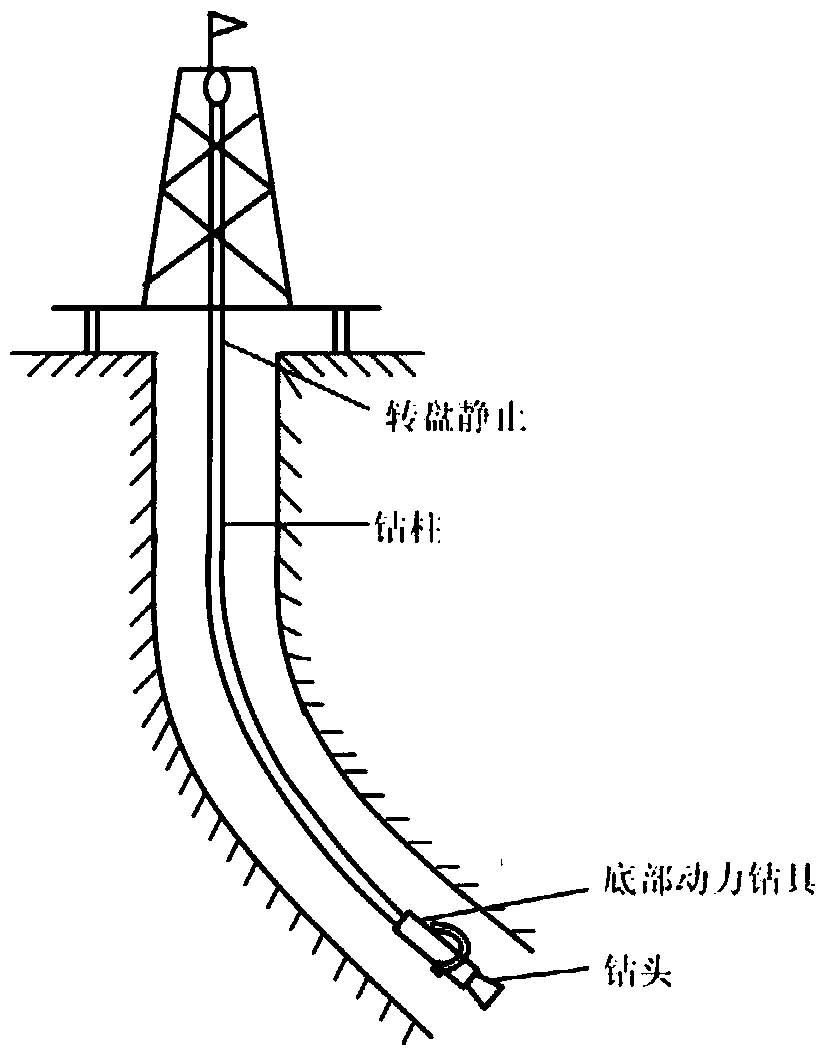

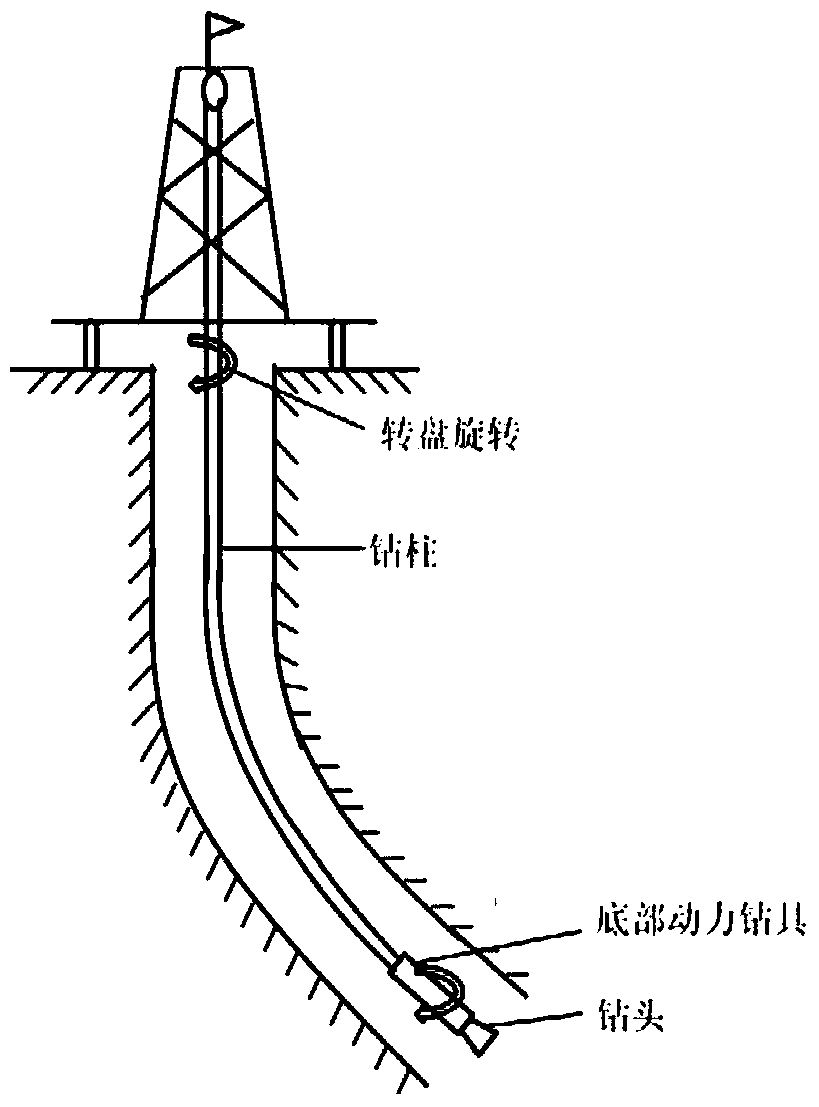

[0061] The core of the present invention is to disclose a drill bit performance evaluation method, which is especially suitable for steerable drilling. Based on the principle of the virtual strength index of the drill bit, the rock breaking efficiency of the drill bit under the steerable drilling mode is established considering the steering drilling driving mode using the bottom dynamic drilling tool. The calculation method comprehensively measures the rock-breaking efficiency and footage of the drill bit, minimizes the impact of drilling conditions on the matching between the drill bit and the formation, and corrects the errors in the performance evaluation of the drill bit in the prior art.

[0062] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com