A floating defoliating roller for sugarcane harvester

A harvester and floating technology, applied in the field of agricultural machinery, can solve the problems of clean peeling, small brushing effect, sugarcane breaking, etc., to reduce the probability of blockage and breakage, ensure flexible contact, and improve poor adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

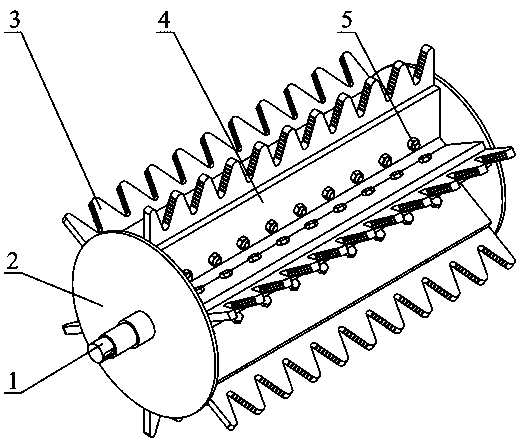

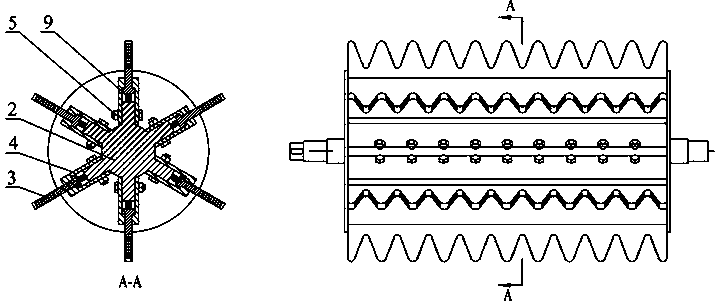

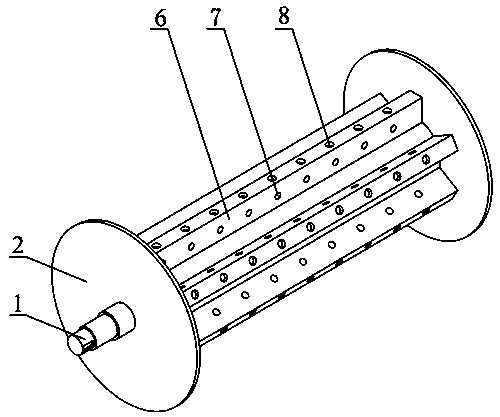

[0021] Such as figure 1 , figure 2 with image 3 The shown floating leaf stripping roller for a sugarcane harvester includes a power input shaft 1, a roller frame 2, a leaf stripping plate 3, a clamping plate 4, a limit spring 9, and the like. In this embodiment, the roller frame 2 is radially welded with six ribs 6 , and several mounting holes 7 and spring limiting holes 8 are evenly distributed on each rib. The leaf stripping plate 3 is elastically connected to the rib plate 6 through several limit springs 9 installed on the spring limit hole 8, and the clamping plate 4 is installed on both sides of the roller frame rib plate 6 through bolts 5 and will The leaf stripping plate 3 is clamped, and the leaf stripping plate is made of flexible materials such as rubber or nylon, and the limit spring is always in elastic contact with the leaf stripping plate and the rib.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com