A square column water cup

A water cup and square column technology, applied in the field of plastic water cups, can solve problems such as affecting work safety and efficiency, internal contents flow out, affecting health, etc., and achieve the effects of improving safety, reducing content, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

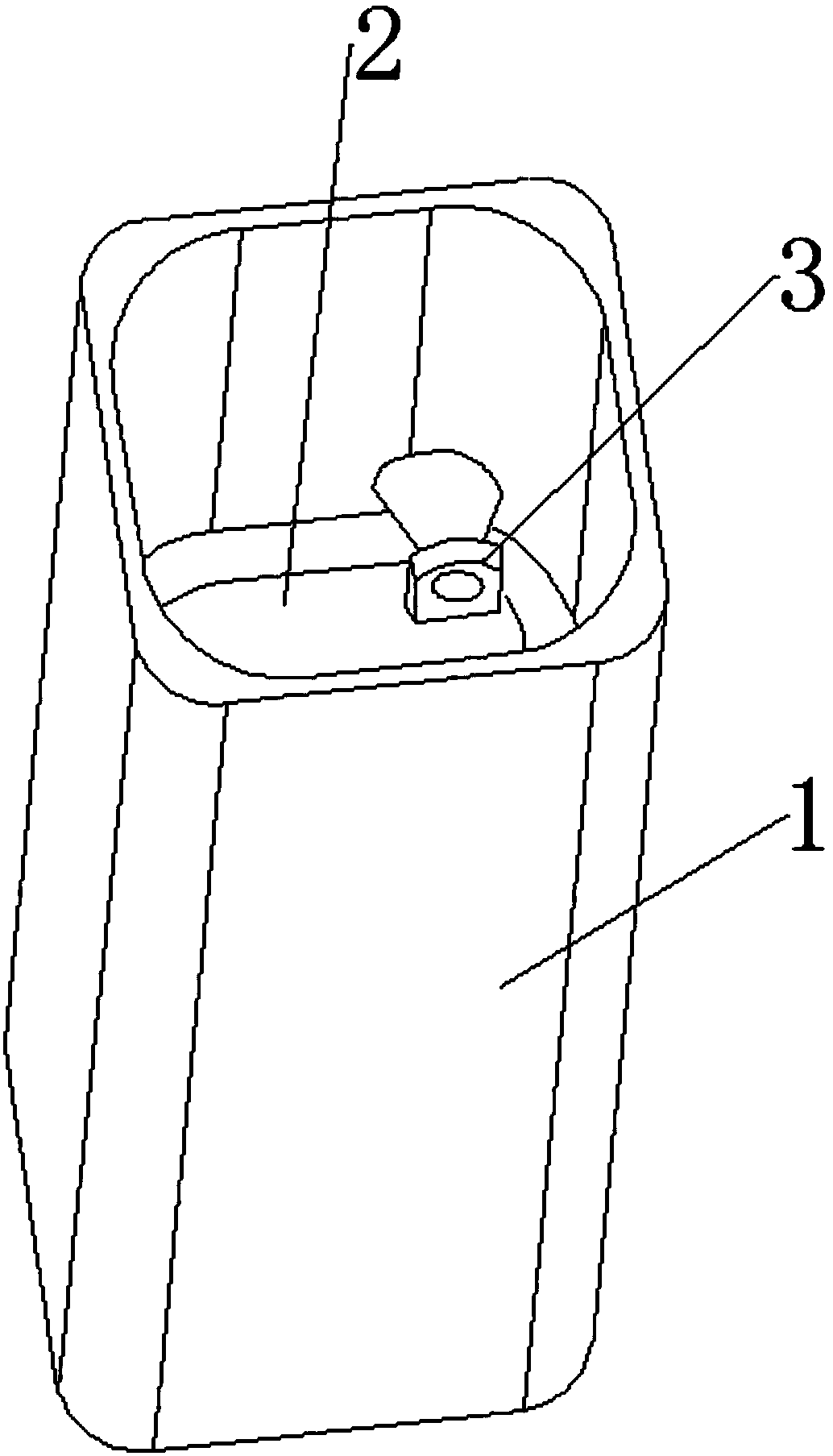

[0027] The square column type water cup in this embodiment comprises a cup bottom, a cup body with a water holding chamber and a cup cover. The cup body is cylindrical, and the upper part of the water holding chamber is cylindrical with the same inner diameter. The side walls are matched with the inner wall of the cylinder so that the cup cover can move up and down in the cylinder. The cup body is made of reinforced PP material, and the inner wall of the cup is provided with a protective layer.

Embodiment 2

[0029] The square column type water cup in this embodiment comprises a cup bottom, a cup body with a water holding chamber and a cup cover. The cup body is cylindrical, and the upper part of the water holding chamber is cylindrical with the same inner diameter. The side walls are matched with the inner wall of the cylinder so that the cup lid can move up and down in the cylinder. The cup body is made of reinforced PP material. The inner wall of the cup is provided with a protective layer. The cup lid also includes a pull button with a button hole. The pull button is arranged on the upper end of the main body.

Embodiment 3

[0031] The square column water cup in this embodiment includes a cup bottom, a cup body with a water holding chamber and a cup cover. The cup body is cylindrical, and the water holding chamber has a cylindrical shape with the same inner diameter. Both are matched with the inner wall of the cylindrical shape so that the cup cover can move up and down in the cylindrical shape. The cup body is made of reinforced PP material, and the inner wall of the cup is provided with a protective layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com