Drum granulator

A drum granulator and machine body technology, applied in the direction of granulating raw materials, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large energy consumption, increased production and processing costs, etc., to reduce energy consumption, The effect of improving production efficiency, energy saving and emission reduction production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

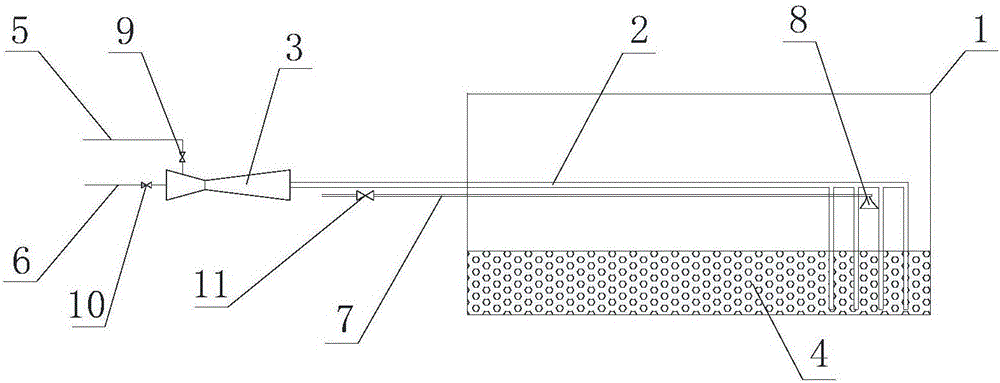

[0010] Such as figure 1 As shown, the drum granulator of the present invention includes a body 1, a mixing tube 2 is installed inside the body 1, the mixing tube 2 is inserted into the body 1, and one end of the mixing tube 2 is provided with a mixing The other end is inserted into a material bed 4, the mixer 3 is provided with an ammonia pipe 5 and a water vapor pipe 6, the mixing pipe 2 is provided with a sulfuric acid pipe 7, and the outlet of the sulfuric acid pipe 7 is A shower head 8 is provided. Ammonia and water vapor come to the material bed 4 through the mixing tube 2, and sulfuric acid comes to the material bed 4 through the sulfuric acid pipe 7. The water vapor and ammonia rise from the bottom, and the sulfuric acid sprays from the top down. The chemical reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com