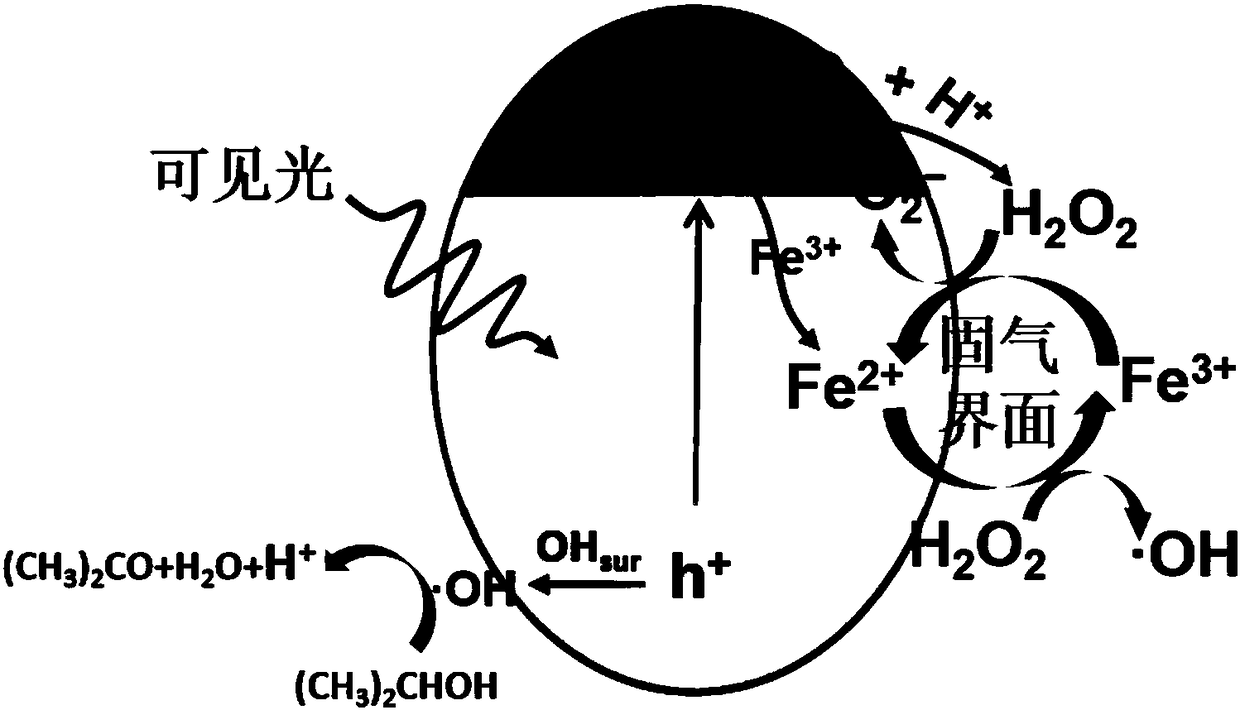

Solid-air interface Fenton reaction coupled carbon nitride photocatalytic material and its preparation and application

A technology of Fenton reaction and catalytic materials, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low performance of organic pollutants, achieve increased photodegradation rate, increased concentration, The effect of photodegradation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of solid-air interface Fenton reaction coupled carbon nitride: Weigh 1.5g of melamine, 7.5g of potassium chloride, and 0.125g of sodium hydroxide, and grind the mixed powder in a mortar for 10-30min. In the crucible, seal the mouth of the crucible with aluminum foil, place it in a muffle furnace and raise the temperature to 550°C and keep it warm for 4 hours. The sintered powder is ground with a mortar, separated by suction filtration with deionized water, After drying for 2h, yellow carbon nitride was obtained. Use the configured ferric chloride solution to load ferric ions, first disperse the yellow carbon nitride sample in deionized water and stir, then add the ferric chloride solution drop by drop to 1.4% of the mass percentage of the carbon nitride sample, at room temperature After stirring for a certain period of time, it is dried in an oven and ground to obtain the final product.

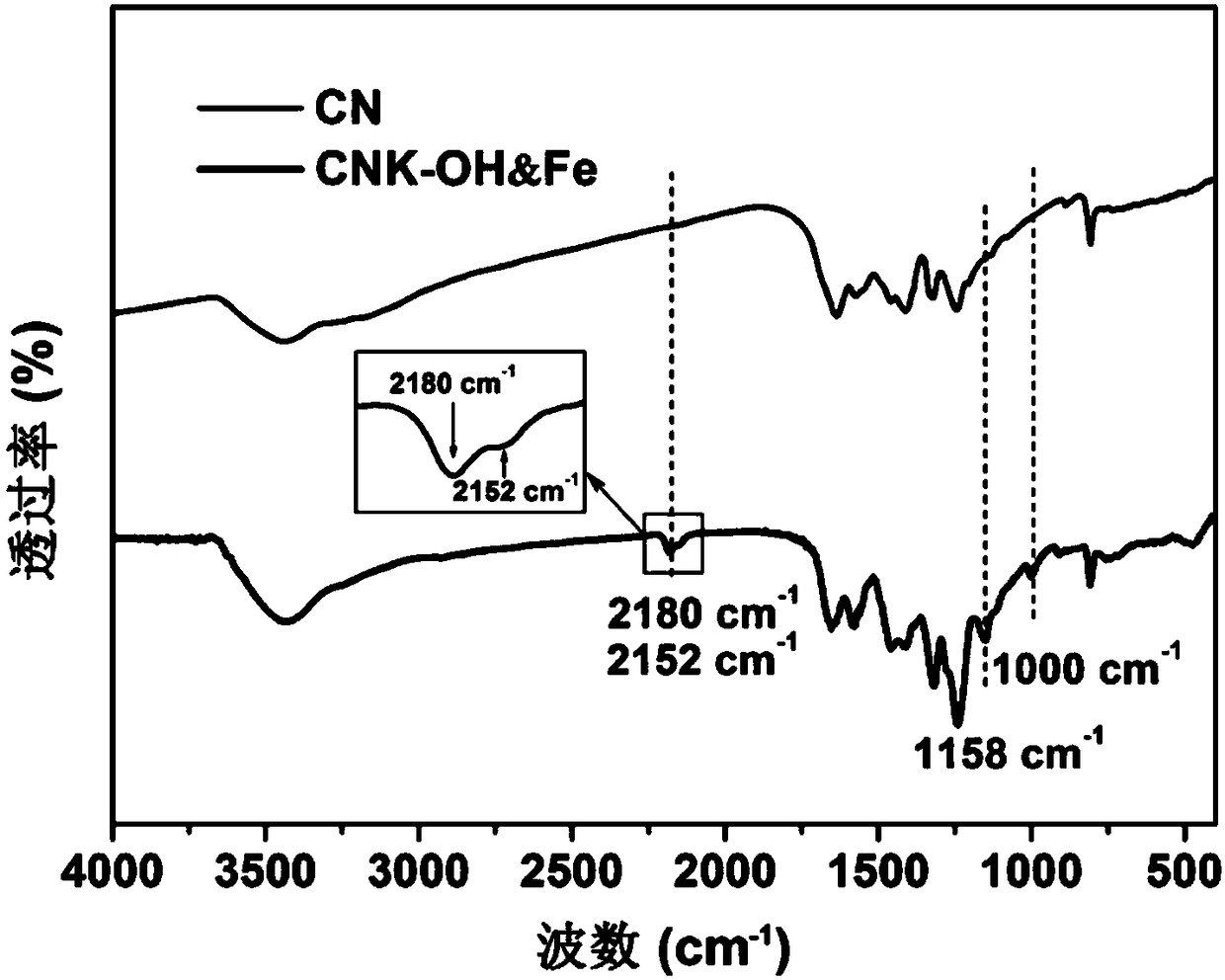

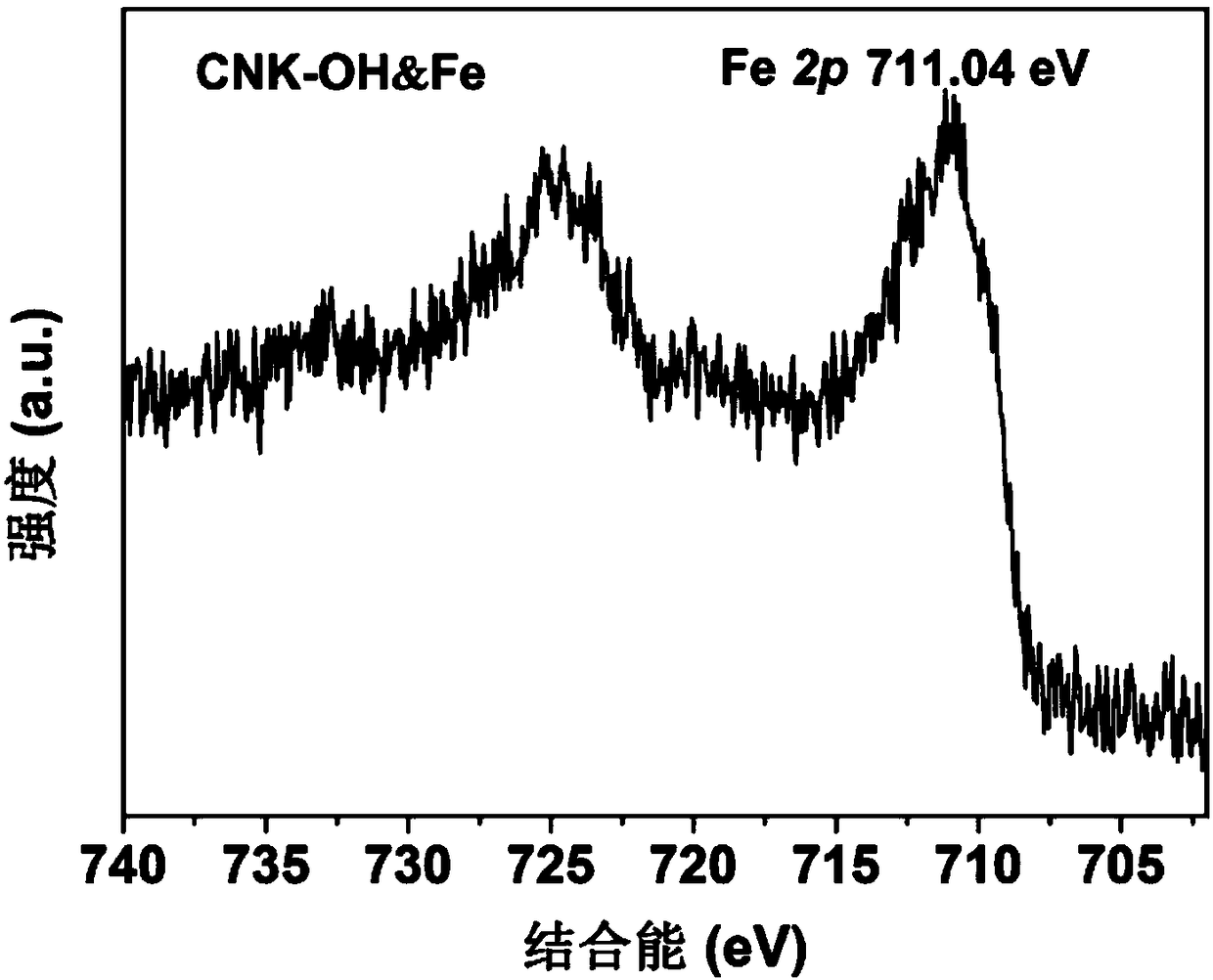

[0031] Some studies on the surface properties of the product (marked ...

Embodiment 2

[0033]The impact of the amount of alkali metal chloride on the product: Weigh four parts of 1.5g of melamine and 0.125g of sodium hydroxide, then add 0.15g, 1.5g, 7.5g, and 30g of potassium chloride to each of the four samples, and mix the raw materials Grind in a mortar for 10 to 30 minutes, mix well, place in a crucible, seal the mouth of the crucible with aluminum foil, put it in a muffle furnace to raise the temperature to 550°C and keep it warm for 4 hours, and use a mortar to sinter the powder Grind, wash with deionized water and separate by suction filtration. The separated sample is dried at 80°C for 4 hours to obtain yellow carbon nitride. Use the configured ferrous sulfate solution to load ferrous ions, first disperse the yellow carbon nitride sample in deionized water and stir, then add the ferrous sulfate solution drop by drop to 3.2% of the mass percentage of the carbon nitride sample, at room temperature After stirring for a certain period of time, it is dried in...

Embodiment 3

[0035] The impact of the amount of alkali on the product: Weigh four parts of 1.5g of melamine and 7.5g of potassium chloride, then add 0.075g, 0.100g, 0.125g, and 0.150g of sodium hydroxide to the four samples. Grind in a bowl for 10 to 30 minutes, mix well, place in a crucible, seal the mouth of the crucible with aluminum foil, put it in a muffle furnace and heat it up to 550°C and keep it warm for 4 hours. The sintered powder is ground with a mortar , washed with deionized water and separated by suction filtration, and the separated sample was dried at 80° C. for 4 hours to obtain yellow carbon nitride. Use the configured chromium nitrate solution to load trivalent chromium ions, first disperse the yellow carbon nitride sample in deionized water and stir, then add the chromium nitrate solution drop by drop to 7.2% of the mass percentage of the carbon nitride sample, and stir at room temperature After a certain period of time, it is dried in an oven and ground to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com