A control method for a tray sorter

A control method and sorting machine technology, applied in sorting and other directions, can solve the problems of luggage slippage and low sorting efficiency, and achieve the effects of low cost, improving sorting efficiency and eliminating slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

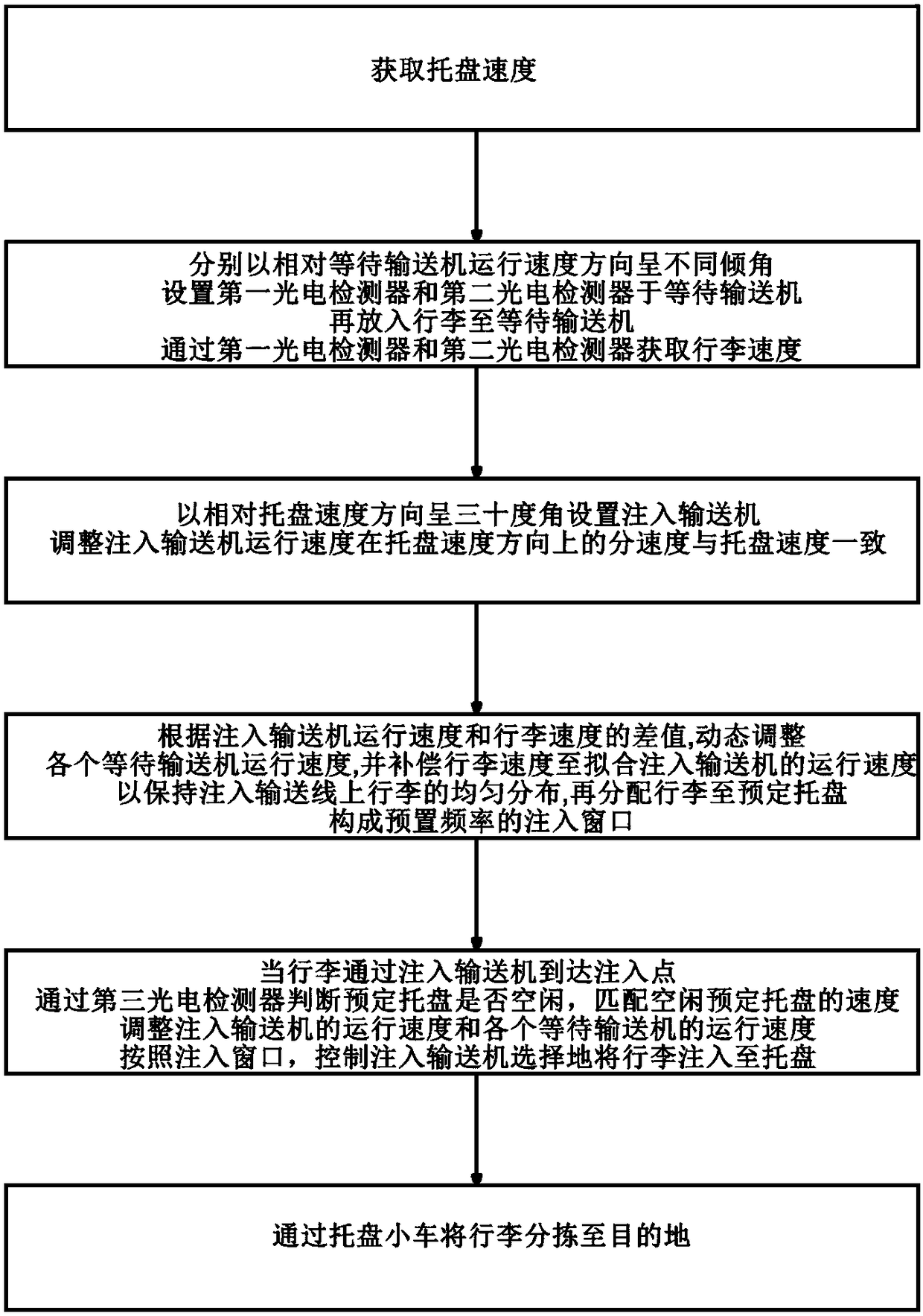

[0037] Ⅰ. Tray introduction line control

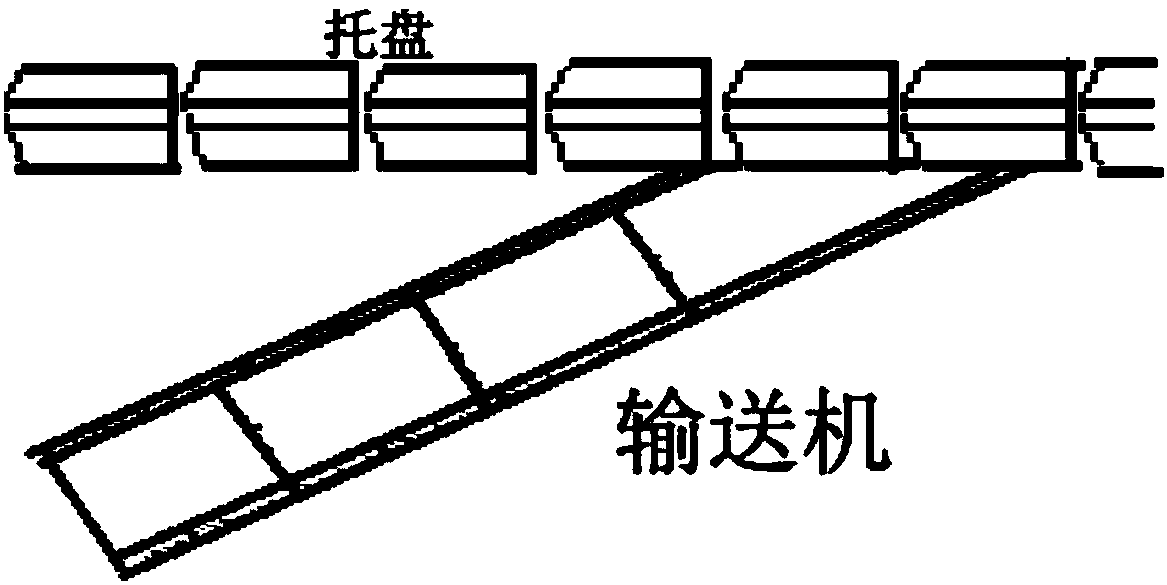

[0038] Ⅰ.1. Injection principle: Each baggage inlet adopts a 30-degree oblique conveyor to inject, and the running speed of the injection conveyor is controlled to keep the pallet direction component speed of the conveyor consistent with the pallet's running speed. In this way, when the luggage is injected onto the tray, the row-to-line displacement error caused by the inconsistency of the two speed directions is effectively avoided, and the luggage can be accurately injected into the middle position of the reserved tray. When the component speed of the luggage in the running direction of the tray is consistent with the speed of the tray, the luggage will not slip when it is injected, causing it to be injected backward, and it will not rush out of the reserved tray forward, such as figure 2 .

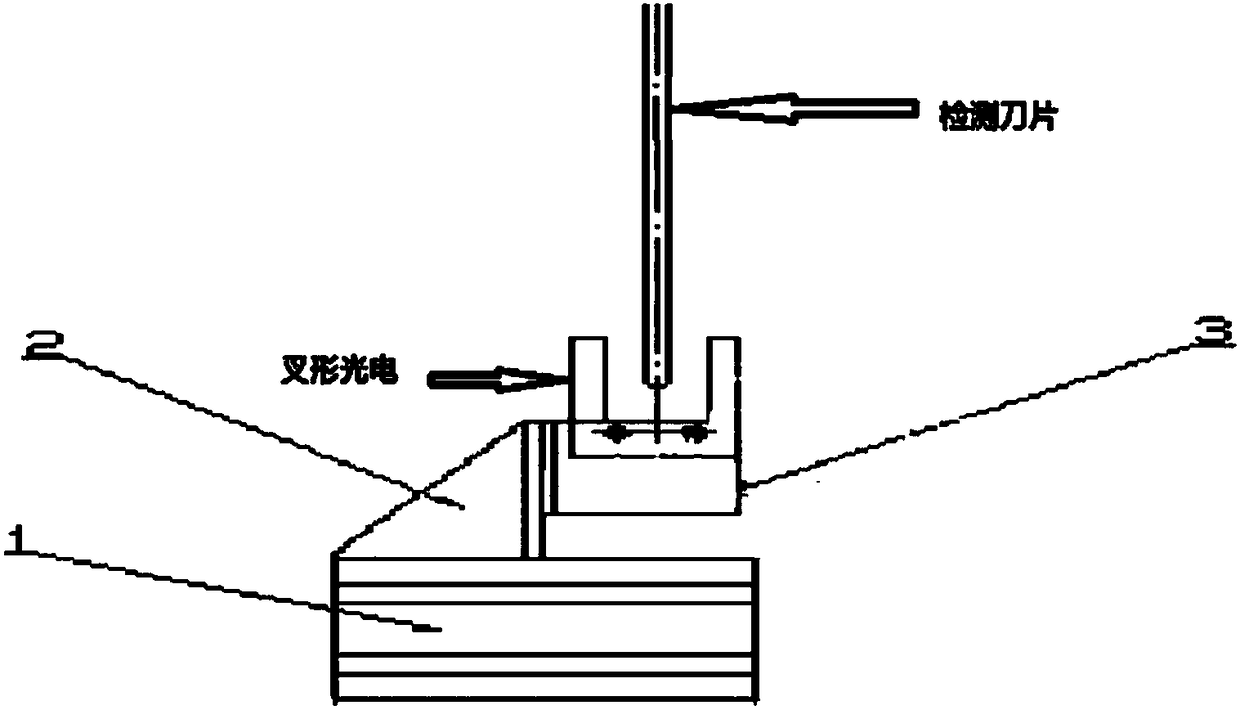

[0039] Ⅰ.2. Accurate injection control: Since the conveyor at the end of each inlet is injected at a 30-degree angle, when the baggage arriv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com