Corrugated oil tank maintenance and cleaning equipment for large and medium-sized transformers in power grids

A technology for corrugated fuel tanks and cleaning equipment, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. The effect of improving work efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing.

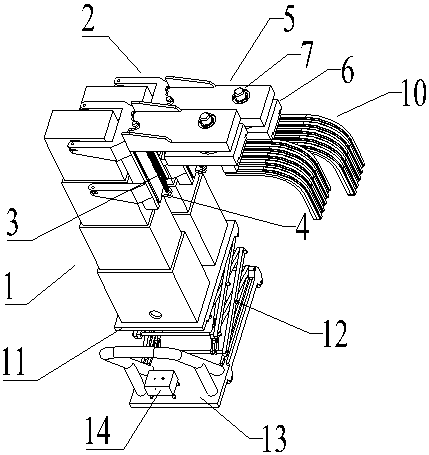

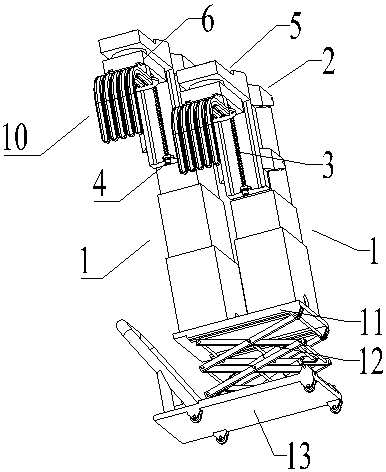

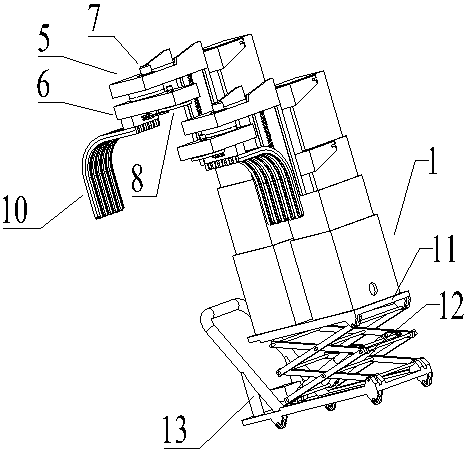

[0061] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 As shown, the corrugated oil tank maintenance and cleaning equipment for large and medium-sized transformers in power grids includes a first lifting device 1, an upper and lower rail frame 2, a screw rod 3, a screw motor 4, an upper and lower frame 5, front and rear rail frames 6, a rotary device 7, Sliding power unit 8, cleaning hook block 9, cleaning hook 10, fixed base plate 11, second lifting device 12, cart 13 and hydraulic station 14, the upper and lower guide rail frames 2 are fixedly arranged on the first lifting device 1, so The screw motor 4 is fixedly arranged on the upper and lower guide rail frames 2 and is fixedly connected with the screw mandrel 3. The upper and lower carriages 5 are sleeved on the screw mandrel 3 and can move on the screw mandrel 3. The rotary device 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com