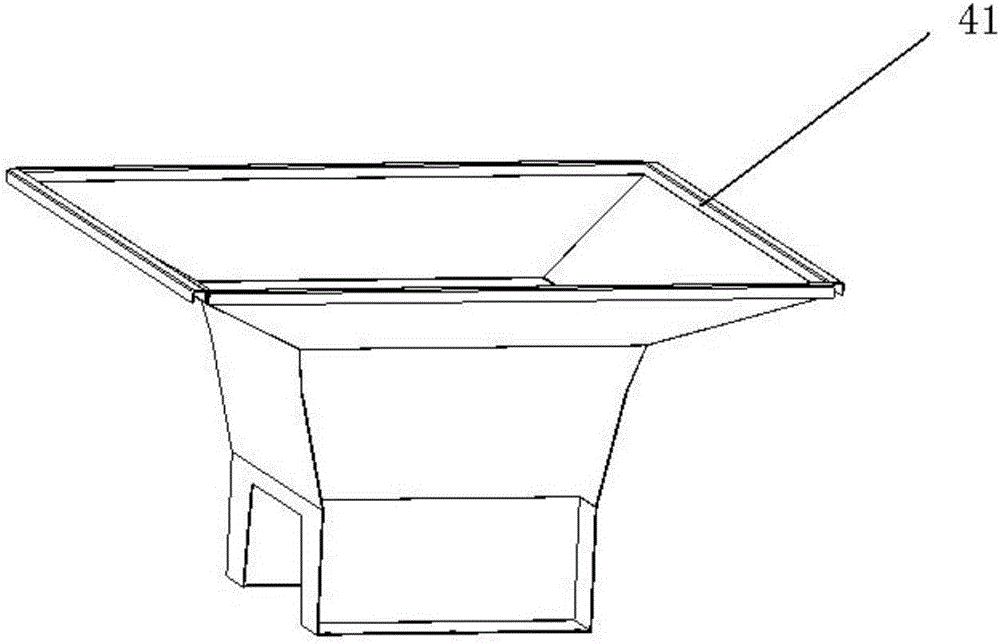

Square shearing machine

A shearing machine and four-corner technology, applied in the field of four-corner shearing machine equipment, can solve the problems of complex device, uncontrollable dough size, uneven dough shearing, etc., to save labor, reduce economic costs and sanitation management costs, and achieve stable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

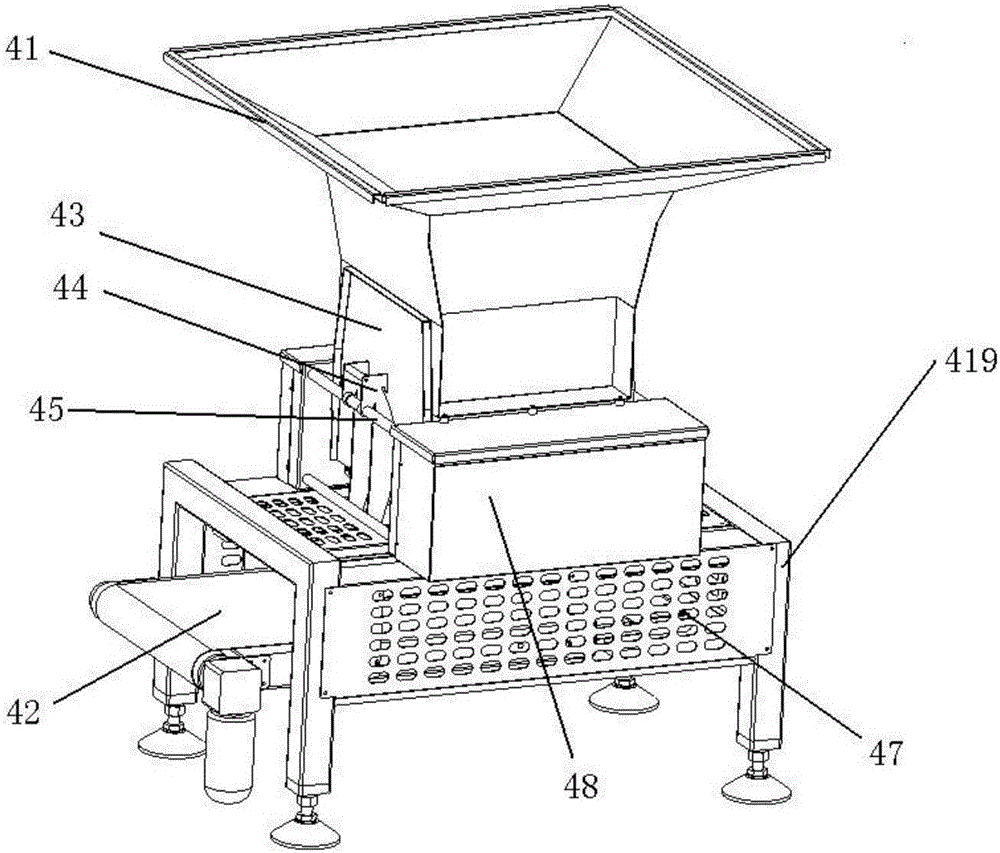

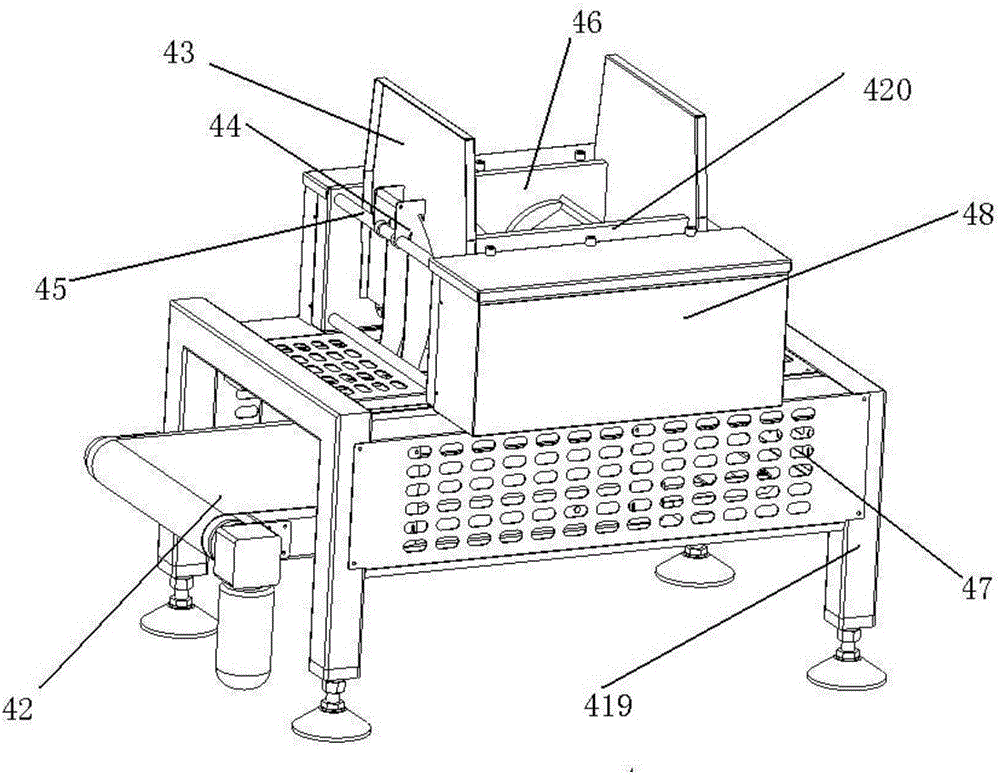

Embodiment 1

[0029] This embodiment discloses a four-corner shearing machine, including a support frame 419 and a conveying device 42, such as figure 2 , 3 As shown, the plate surface of the support frame 419 is provided with a discharge hole 417, the discharge hole 417 runs through the plate surface of the support frame, the conveying device 42 is arranged below the discharge hole 417, the discharge hole 417 is a square hole, along the Respectively be provided with a support plate 46 vertically on the opposite two sides of the square hole, two support plates 46 are arranged relatively parallel and are vertically fixed with the plate surface of support frame 419 respectively, wherein a support plate 46 is provided with two round Shaft hole, the circular shaft hole runs through the support plate 46, the axis of the circular shaft hole is perpendicular to the surface of the support plate 46, the centers of the two circular shaft holes are located on the same horizontal line, and the opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com