Steel tube cutting machine

A cutting machine and cutting mechanism technology, which can be applied to pipe shearing devices, shearing devices, accessories of shearing machines, etc., can solve problems such as blade damage, complex structure, and increased product production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

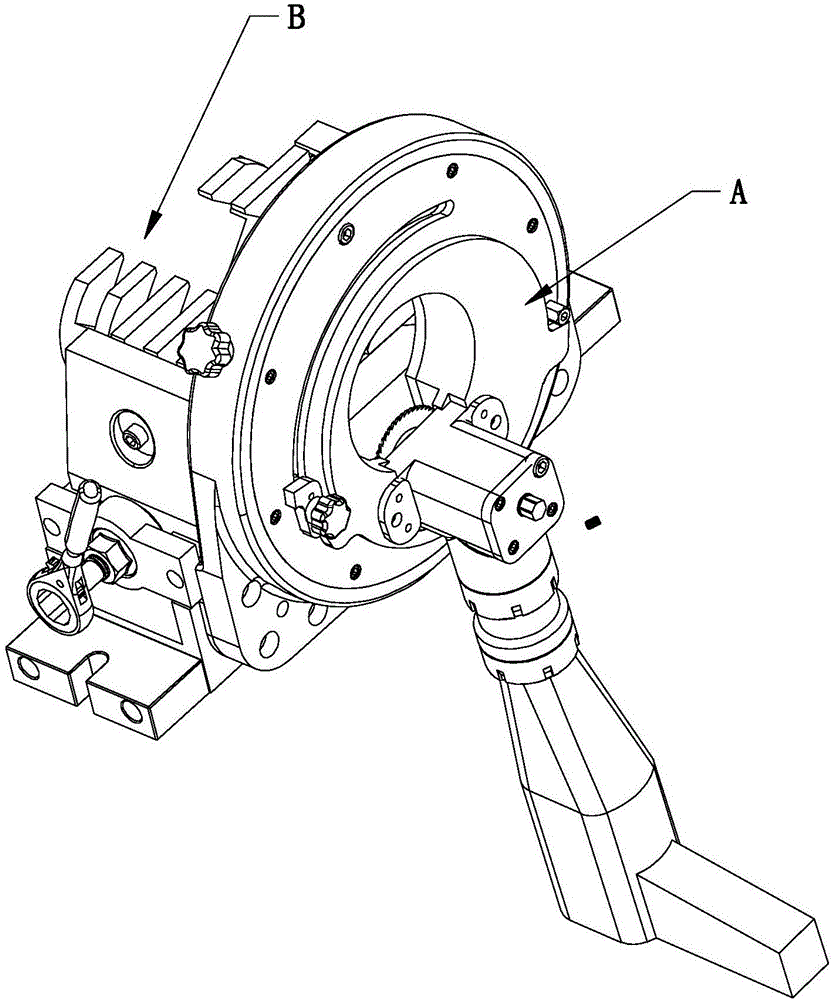

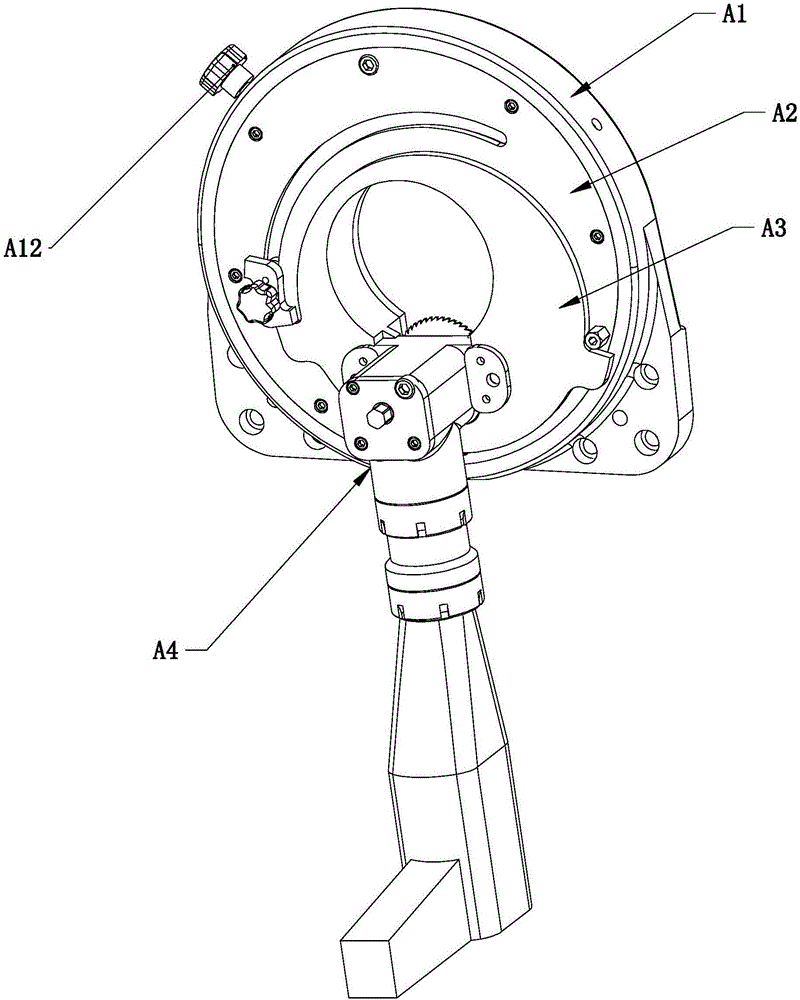

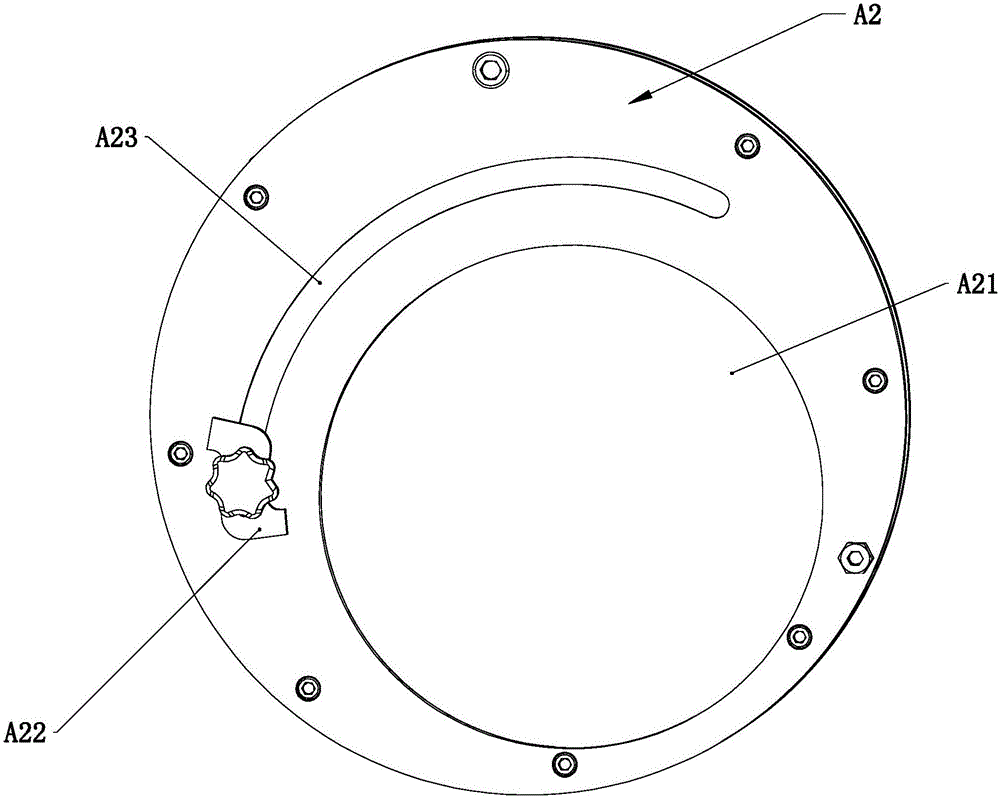

[0025] Such as figure 1 — Figure 13 As shown, a steel pipe cutting machine includes a cutting mechanism A and a clamping mechanism B. The cutting mechanism A includes a bracket A1, a rotating disk A2, a feed control rotating disk A3 and a blade cutting device A4. Here we will explain The blade cutting device A4 is a device that drives the blade to rotate through a motor. It is also common in the general market. Its main function is to realize the function of blade rotation. It is circular, and the rotating disk A2 is rotated and installed on the circular through hole A11 of the bracket A1. The rotating disk A2 is eccentrically provided with a circular through hole A21, and the feed control dial A3 is rotated and installed on the circular through hole A21. Among them, a cutting through hole A31 is provided at an eccentric position on the feed control turntable A3, and the blade cutting device A4 is fixedly arranged on the feed control turntable A3, and the blade cutting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com