CNC cutting machine

A cutting machine and cutting machine technology, applied in metal processing mechanical parts, clamping, supporting and other directions, can solve the problems of low cutting precision, poor safety, low work efficiency of manual cutting wire mesh, etc., to achieve low noise, accurate cutting, Cutting precision for safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

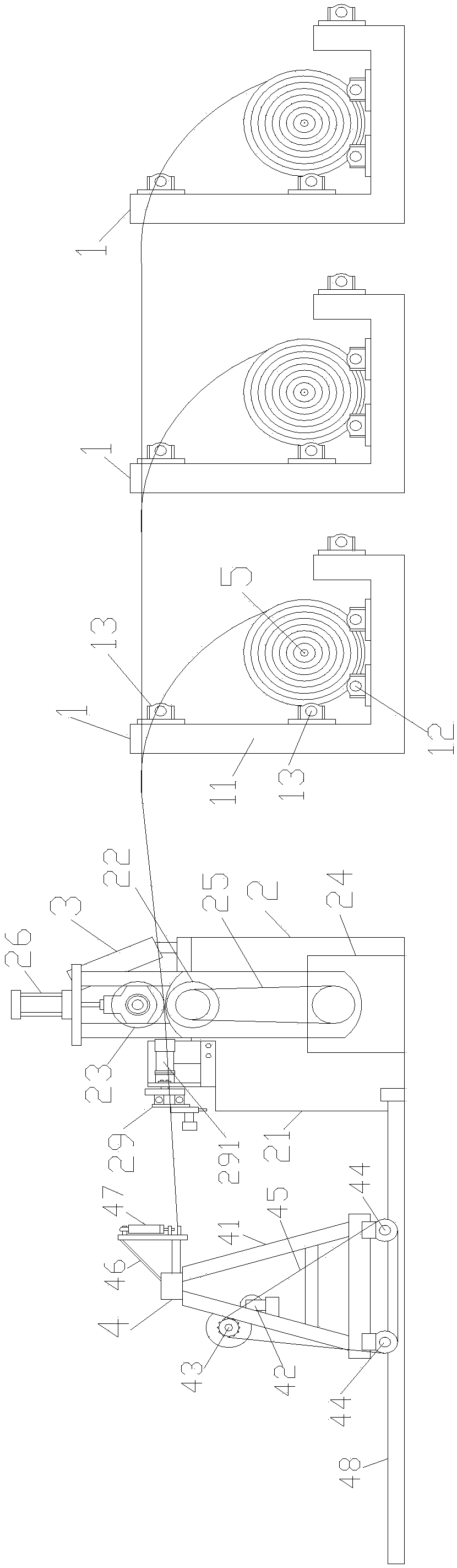

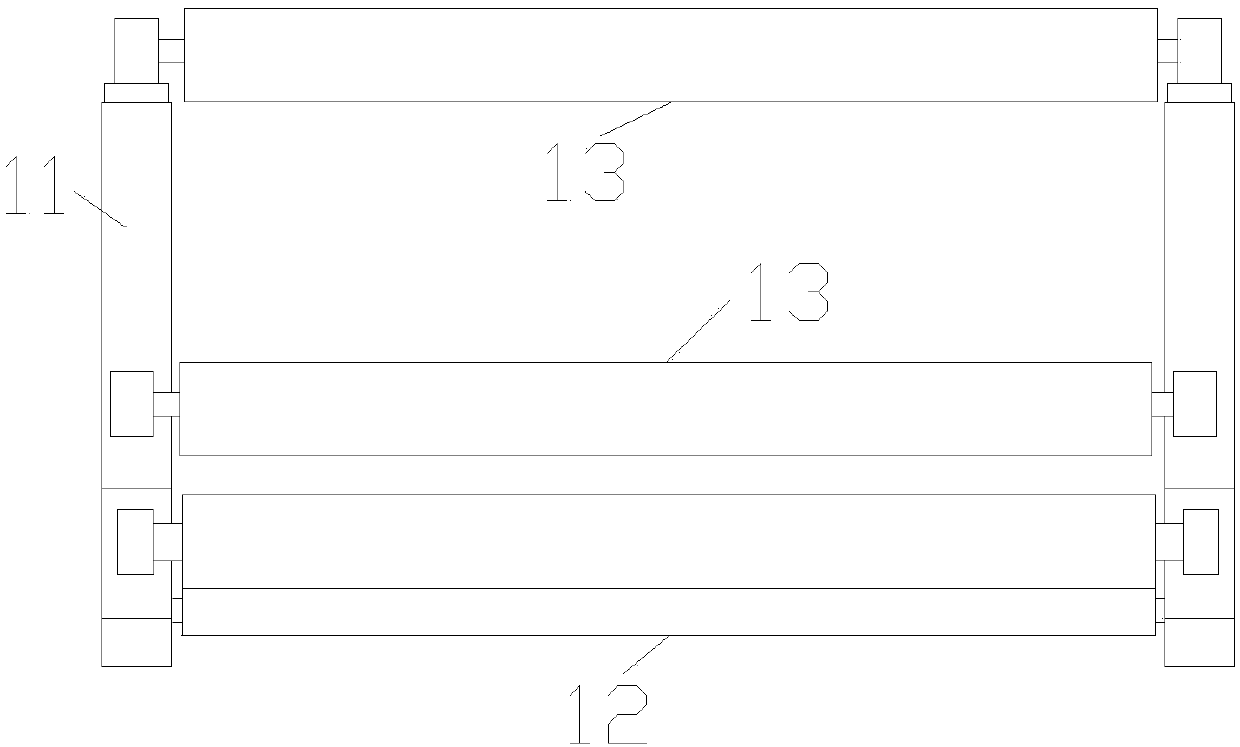

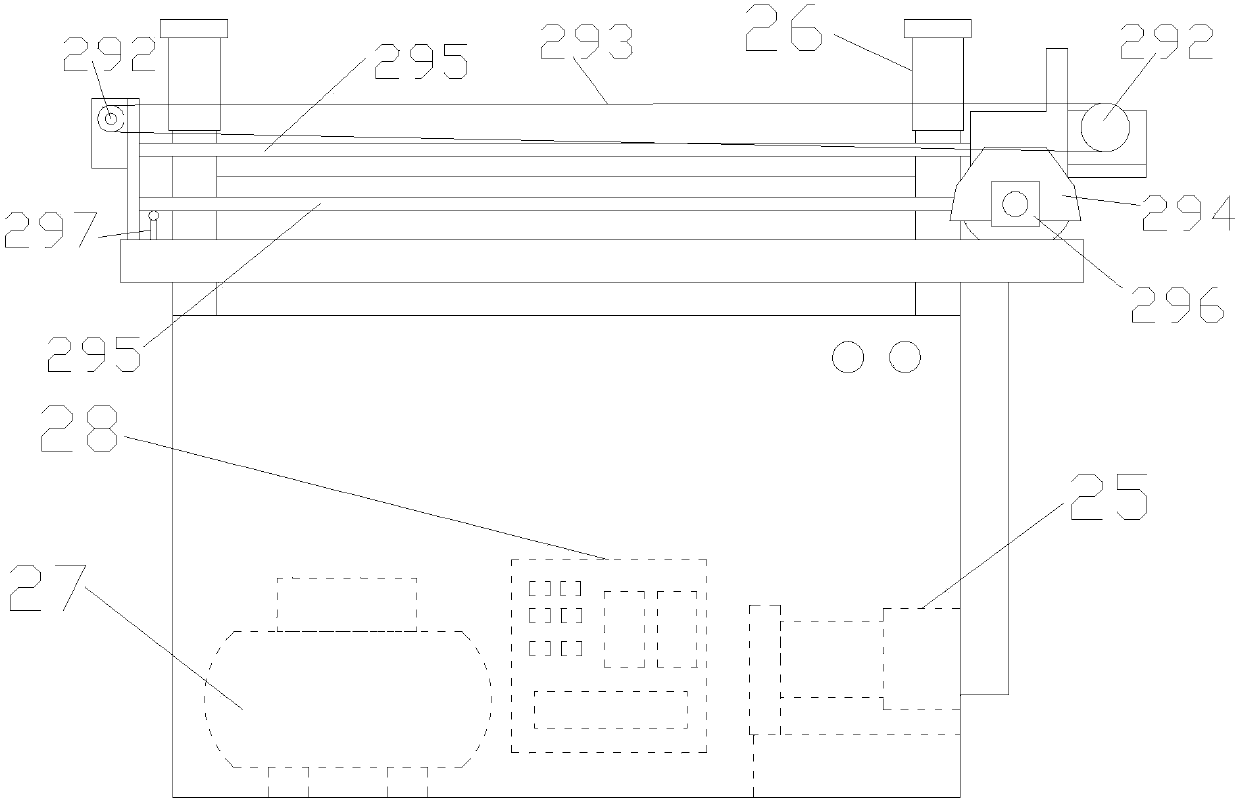

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a numerical control cutting machine is composed of several feeding roller frames 1, cutting machine 2, console 3 and flattening frame 4, and the lower part of the frame body 11 of the feeding roller frame is provided with several supports for placing silk screen rolls 5 Roller 12, the wire mesh is connected with the cutting machine 2 through the guide roller 13 on the frame body 11; the driving motor 24 is set in the table body 21 of the cutting machine 2, and the driving motor 24 is connected with the discharge lower roller 22 on the table body through the transmission belt 25 The upper discharge roller 23 is located above the lower discharge roller 22, and an adjustment cylinder 26 is arranged at both ends of the table body 21. The piston rod of the adjustment cylinder 26 is connected with the upper discharge roller 23, and the air pump 27 set in the table body 21 drives Adjust the cylinder 26 so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com