Plate grinding device

A plate, horizontal technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of high maintenance cost of grinding device, flying into people's eyes, endangering personal safety, etc., and achieves strong novelty. , Low maintenance cost, and the effect of ensuring physical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

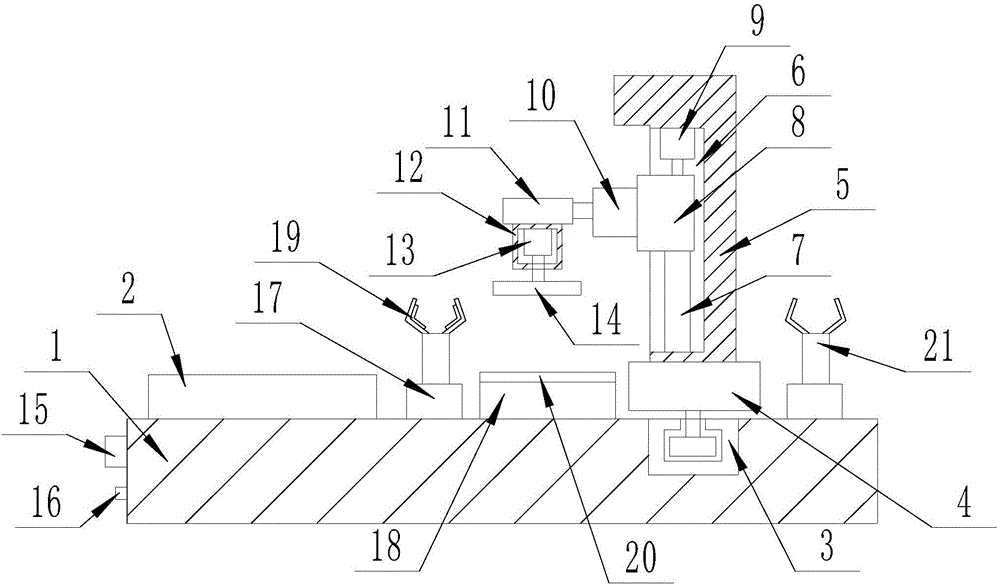

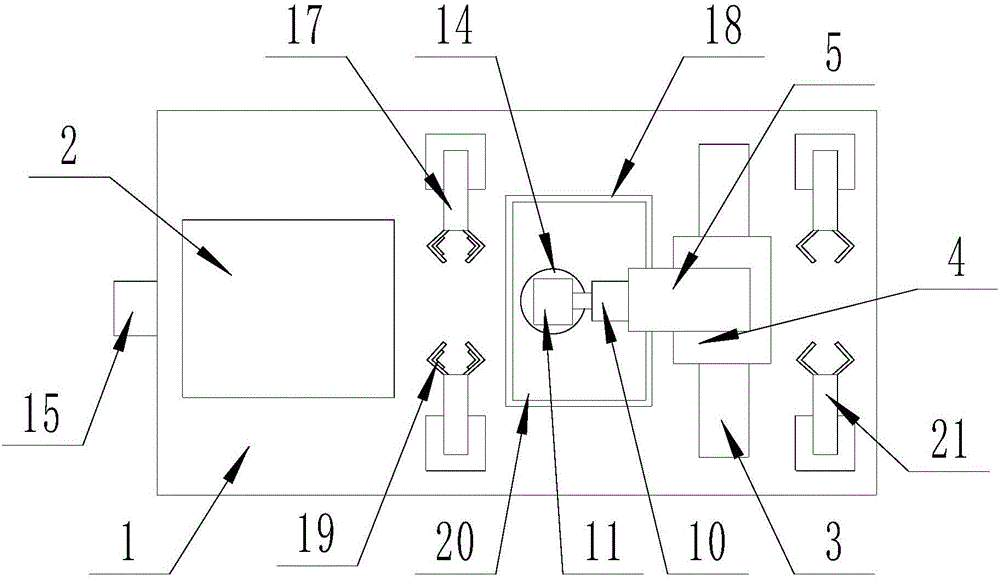

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a plate grinding device includes a workbench (1), a conveyor belt (2) is provided on one side of the upper surface of the workbench (1), and the other side of the upper surface of the workbench (1) is processed with a horizontal Slide rail (3), described horizontal slide rail (3) is provided with electric trolley (4), and described electric trolley (4) upper surface is provided with support frame (5), and described support frame (5) one side A vertical slideway (6) is processed on the surface, and a slide rail (7) is provided inside the vertical slideway (6), and a slide block (8) is provided on the slide rail (7). The inner upper surface of the slideway (6) is provided with a No. 1 telescopic cylinder (9) whose telescopic end is downward, and the telescopic end of the No. 1 telescopic cylinder (9) is fixedly connected with the slider (8), and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com