Automatic pressure regulation system of multi-color flexographic roller printing machine based on fpga

A technology of automatic pressure regulation and printing machine, applied in the general parts of printing machinery, printing machine, rotary printing machine and other directions, can solve the problems of low pressure regulation efficiency, improve efficiency, shorten communication cycle, smooth and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

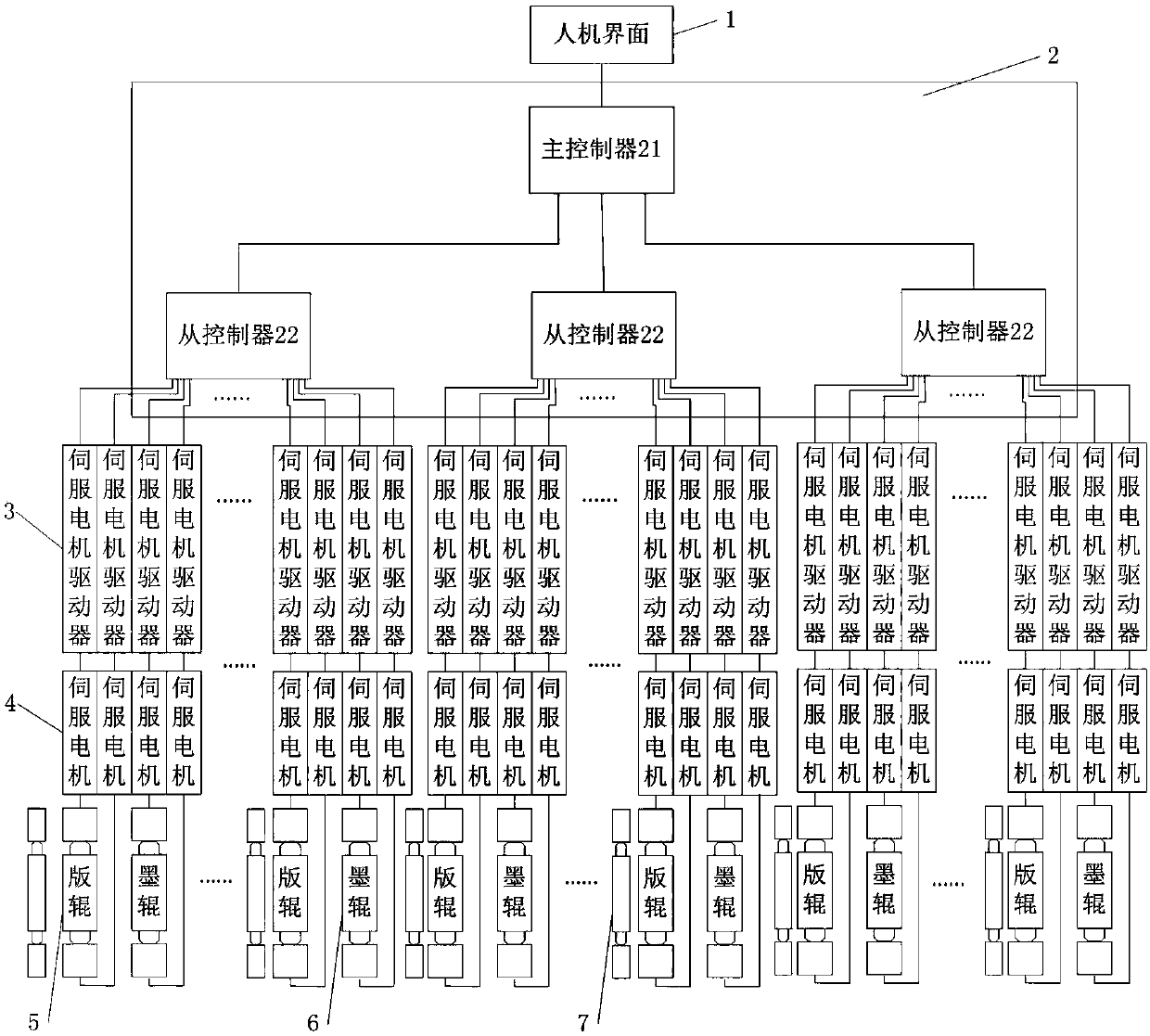

[0022] refer to figure 1 , the present invention includes a man-machine interface 1, a controller 2 and a plurality of multi-color pressing mechanisms; wherein,

[0023] Man-machine interface 1 adopts HMI, including data input interface, instruction sending interface and data display interface, for man-machine interaction.

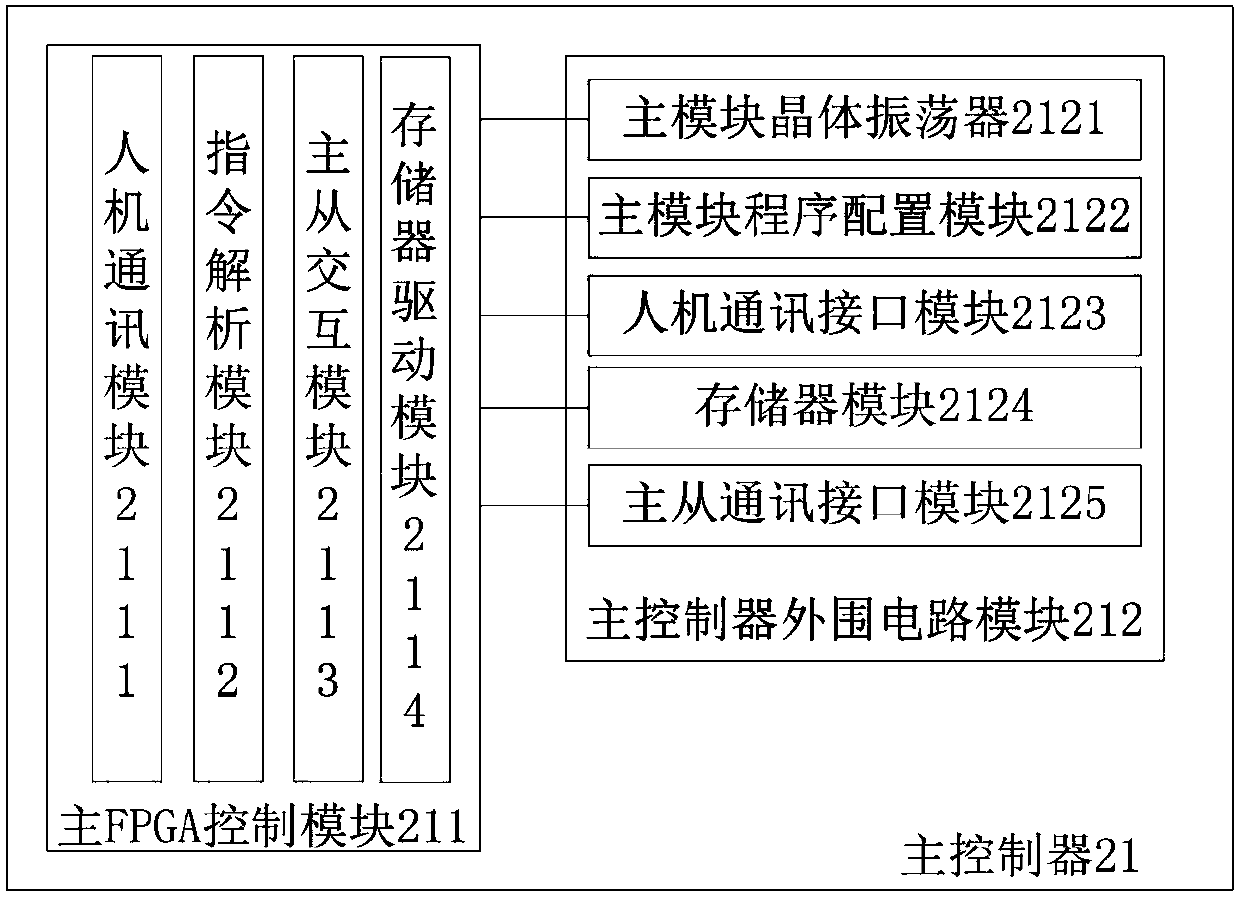

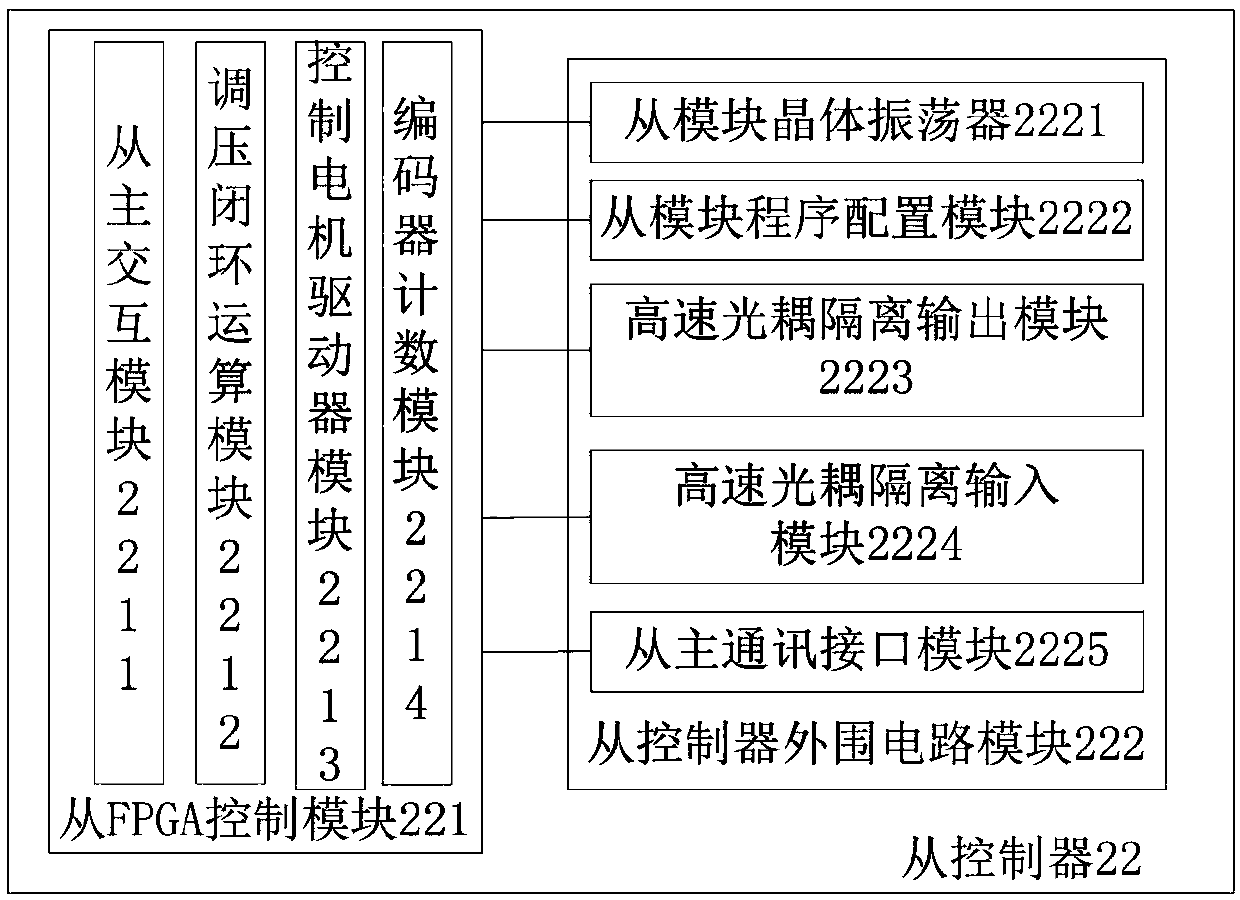

[0024] Controller 2 includes a master controller 21 and a plurality of slave controllers 22, the structure of the master controller 21 is as figure 2 As shown, its processor uses FPGA, which includes 150 I / O interfaces, 1840 logic array blocks, 4 transceivers and 29440 logic elements, with a total memory of 1080bit, a maximum operating frequency of 200MHz, and a data rate of 2.5 Gbps; from the structure of the controller 22 such as image 3 As shown, its processor adopts FPGA, and in this embodiment, the FPGA of slave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com