A structure based on ng engine passenger car heater pipeline

An engine and heater duct technology, applied in vehicle parts, heating/cooling equipment, transportation and packaging, etc., can solve the problems of NG engine radiator cooling capacity decrease, engine internal air resistance increase, engine easy to lack of coolant and other problems , to achieve the effect of low cost, avoidance of backflow phenomenon and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

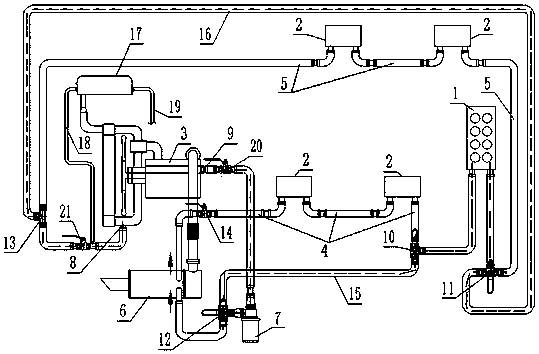

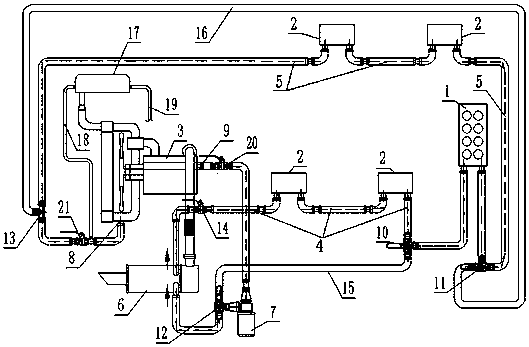

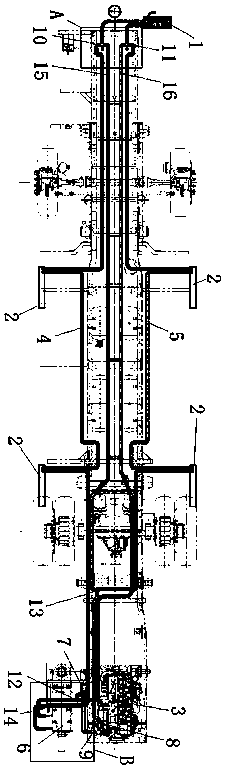

[0027] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

[0028] A structure based on an NG engine passenger car heating pipeline, including a defroster 1, an NG engine 3, a water pump 7, an exhaust gas heater 6, a water outlet main pipeline 4, and a return water main pipeline 5, where the water outlet main pipeline 4 and the return water A plurality of radiators 2 are respectively arranged on the main pipeline 5, which also includes a first pipeline 15 and a second pipeline 16; a first two-position three-way valve 10 is provided at the water inlet of the defroster 1, and the defrosting A second two-position three-way valve 11 is provided at the water outlet of the device 1, a third two-position three-way valve 12 is provided at the water outlet of the water pump 7, and a three-way pipe 13 is provided at the engine return port 8 of the NG engine 3. , the engine water outlet 9 of the NG engine 3 is connected to the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com