Air inlet system on passenger car with front engine

A technology of air intake system and engine, which is applied in the direction of power plant gas intake, power plant, vehicle components, etc. It can solve the problems of weak versatility, inapplicability to front-engine passenger cars, low air intake efficiency, etc., and achieve universality Strong, easy to install, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

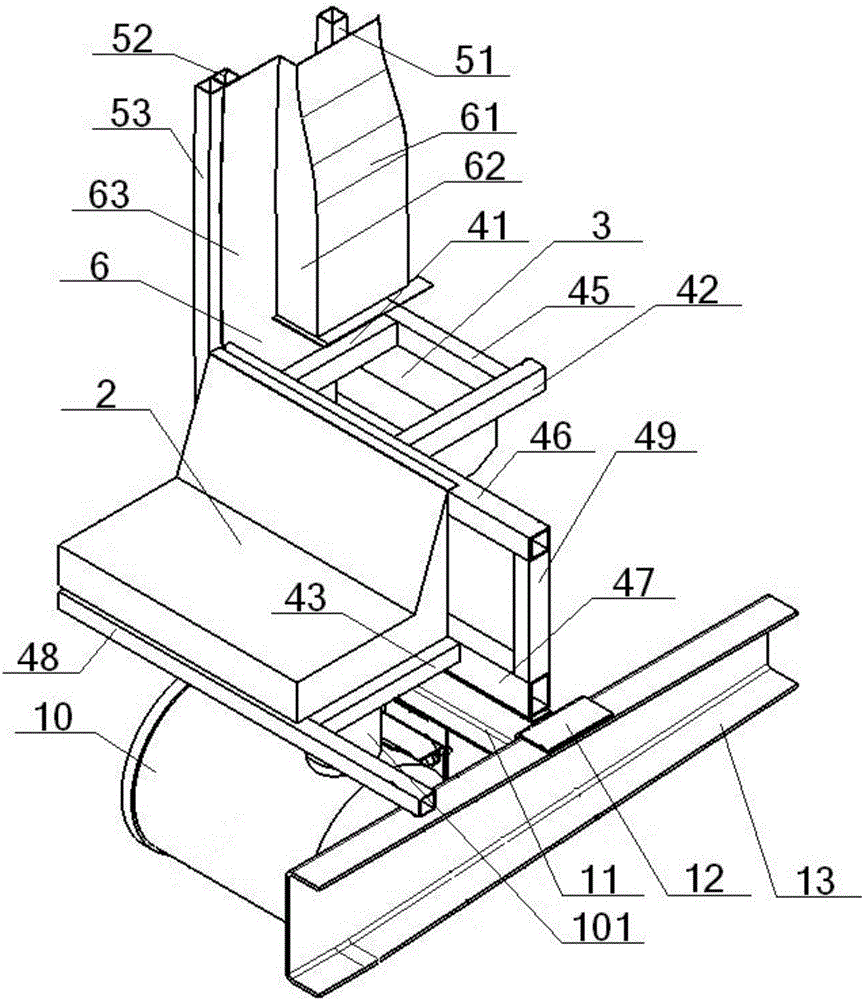

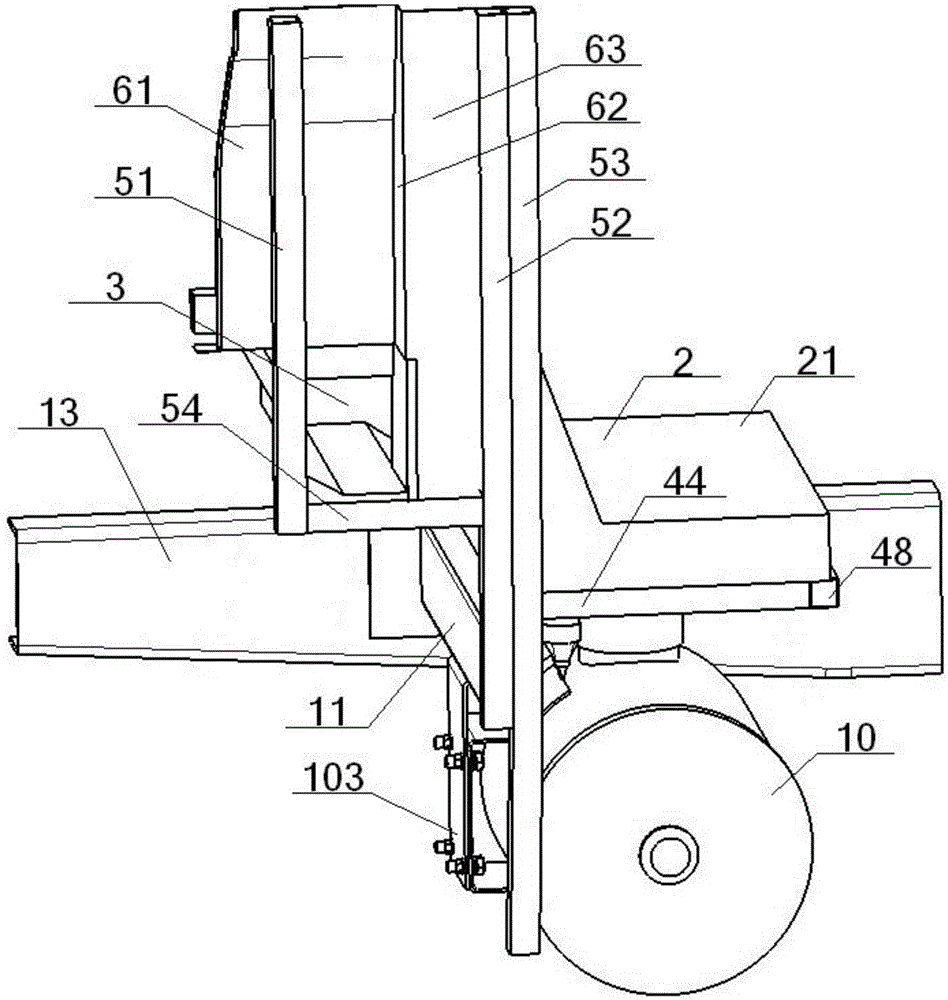

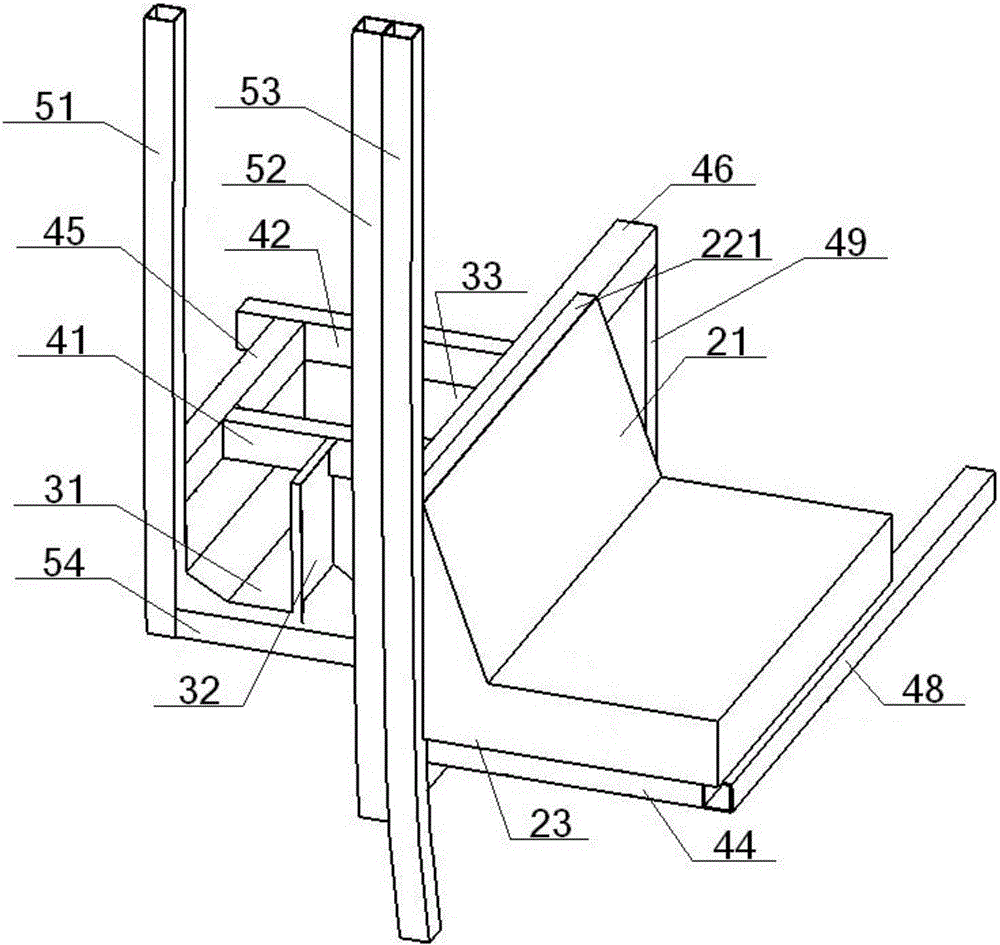

[0091] see Figure 1 to Figure 13 , an air intake system on a front engine passenger car, comprising an air intake grille 1, an upper section air duct 7, an air intake channel and an air filter 10, and the upper section air duct 7 includes a door outer panel 71, a car door inner panel 72 is connected with the upper air intake unit 6, the bottom of the door inner panel 72 is connected with the top of the upper air intake unit 6, the door inner panel 72 and the upper air intake unit 6 are arranged opposite to the outer door panel 71, and the outer door panel 71 is An air intake grille 1 is provided, and the air intake channel includes a forward air channel 8 and a rear air intake channel 9, the forward air channel 8 includes a floor frame 4 and the forward air unit 3 connected thereon, and the rear air intake channel 9 includes a floor The frame 4 and the rear air intake unit 2 connected thereto, the top of the upper section air duct 7 communicates with the air outside the vehic...

Embodiment 2

[0095] Basic content is the same as embodiment 1, the difference is:

[0096] The forward air bottom plate 31 includes a first bottom connecting plate 311, a second bottom connecting plate 312, a third bottom connecting plate 313 and a fourth bottom connecting plate 314 connected in sequence, the first bottom connecting plate 311 is a vertical plate, The second connecting plate 312 of the base plate, the fourth connecting plate 314 of the base plate are inclined plates, the third connecting plate 313 of the base plate is a flat plate, the length of the first connecting plate 311 of the base plate, the second connecting plate 312 of the base plate, and the third connecting plate 313 of the base plate are the same, The fourth connecting plate 314 of the bottom plate is shorter than the third connecting plate 313 of the bottom plate. Align, the inner sides of the first connecting plate 311 of the bottom plate, the second connecting plate 312 of the bottom plate, and the third con...

Embodiment 3

[0099] Basic content is the same as embodiment 2, the difference is:

[0100] The angle between the first connecting plate 311 of the bottom plate and the second connecting plate 312 of the bottom plate is 120 degrees, the angle between the second connecting plate 312 of the bottom plate and the third connecting plate 313 of the bottom plate is 150 degrees, and the third connecting plate 313 of the bottom plate is 150 degrees. The included angle between the plate 313 and the fourth connecting plate 314 of the bottom plate is 145 degrees; between the first connecting plate 311 of the bottom plate, the second connecting plate 312 of the bottom plate, the third connecting plate 313 of the bottom plate, and the fourth connecting plate 314 of the bottom plate The junctions between are all arc transition structures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com