Motorcycle housing

A car shell and sub-shell technology, applied in the field of car shells that are easy to demould and assemble, can solve the problems of reducing the freedom of appearance design and increasing the cost of mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

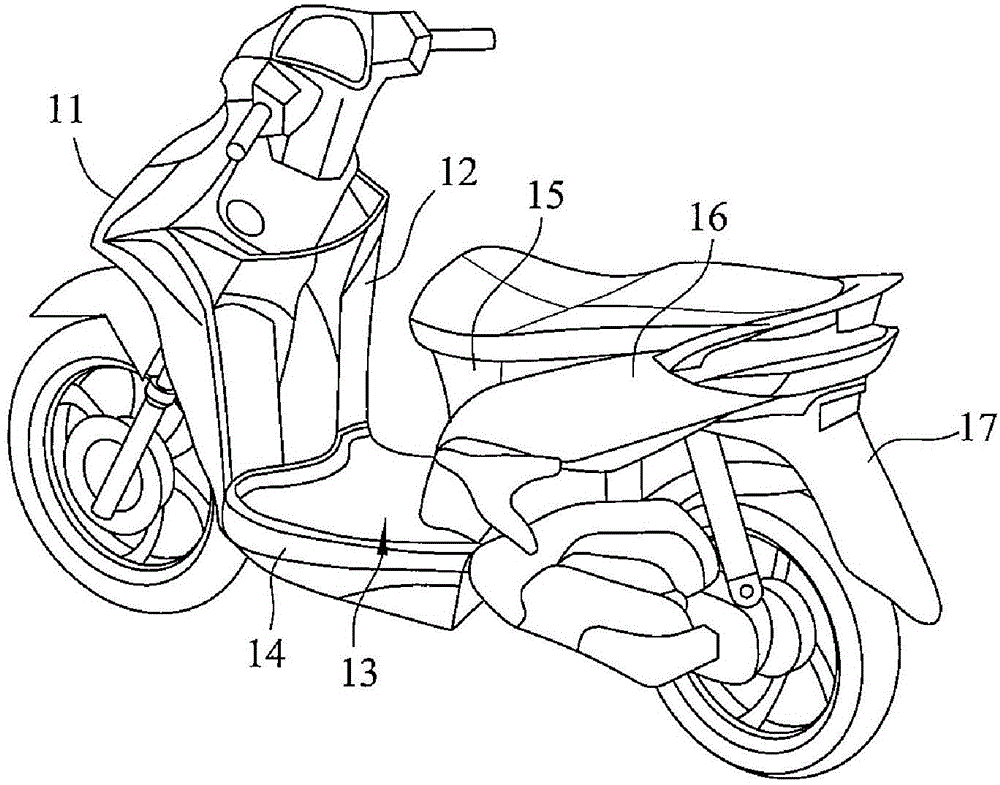

[0018] refer to Figure 4 , the car shell of the present invention includes a plurality of sub-housings that can be combined with each other, and the sub-housings are respectively a front cover 21, a rear cover 22 combined on the rear side of the front cover 21, a combined The pedal 23 on the rear side of the lower end of the rear cover 22, two edge-receiving cover plates 24 respectively combined on the two longitudinal sides of the pedal 23, and one combined in the center of the rear side of the pedal 23 A cover plate 25, two side cover plates 26 respectively assembled on two sides of the central cover plate 25, and a tail cover plate 27 assembled between the rear sides of the side cover plates 26.

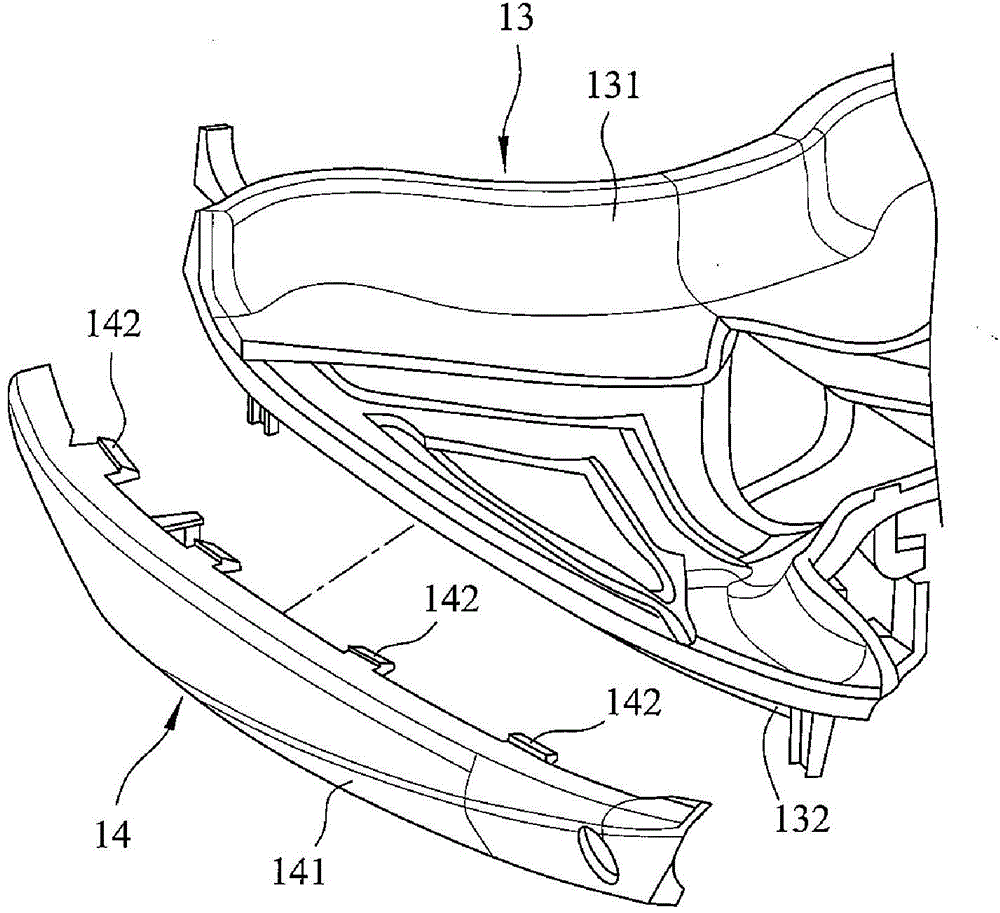

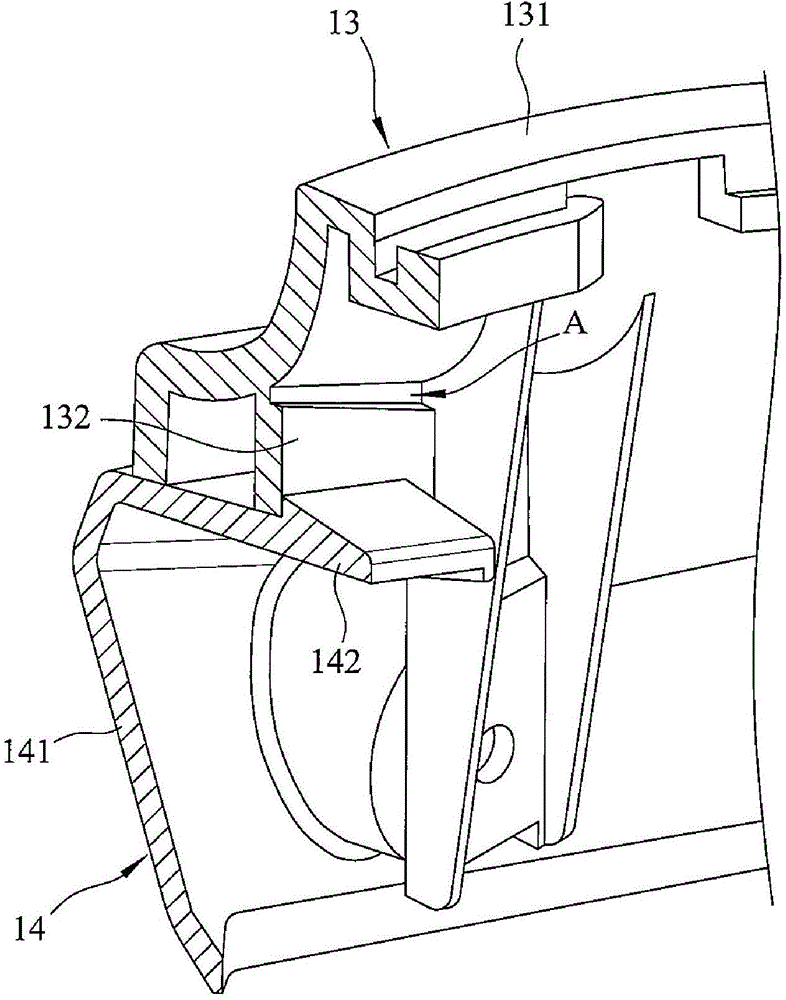

[0019] refer to Figure 5 , 6 , is the first embodiment of the car shell of the present invention. This embodiment is described with the combination of the pedal 23 and one of the edge cover plates 24. The pedal 23 includes a pedal body 231, Two supporting parts 232 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com