Very large floating structure module connecting device based on flexible rods

A floating structure and connecting device technology, applied in fixed devices, floating buildings, ships, etc., can solve the problems of connection failure, structural damage, large stress on connecting components and their bases, etc., to achieve clear functions, structural Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

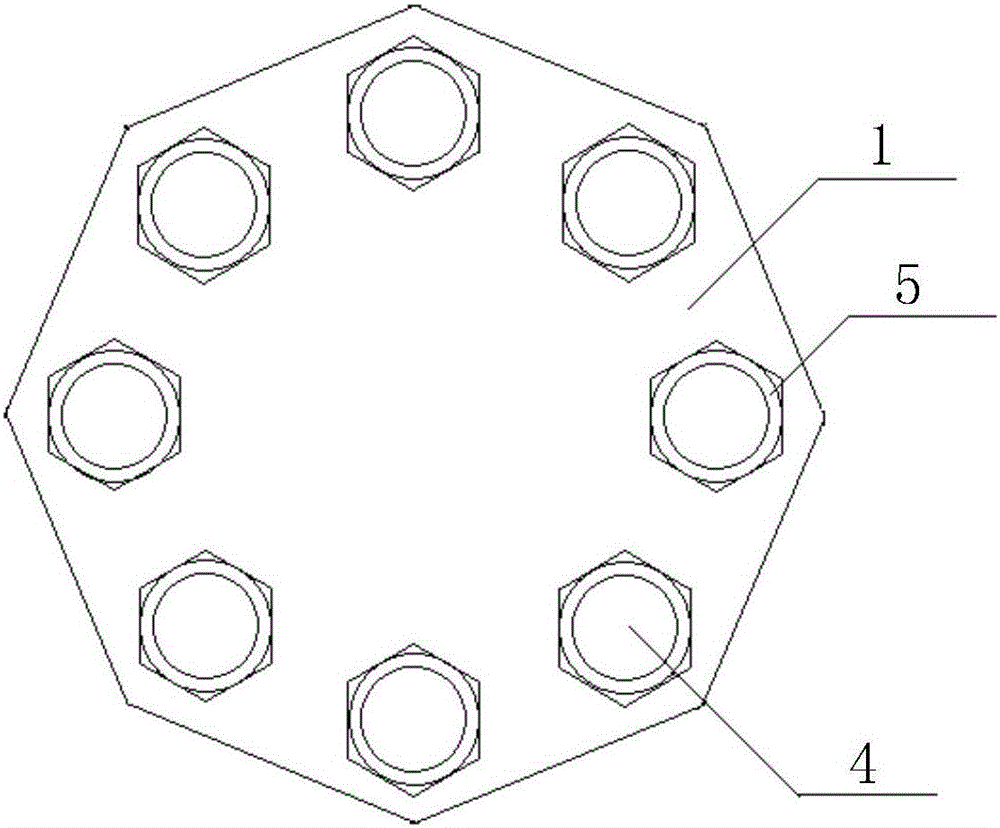

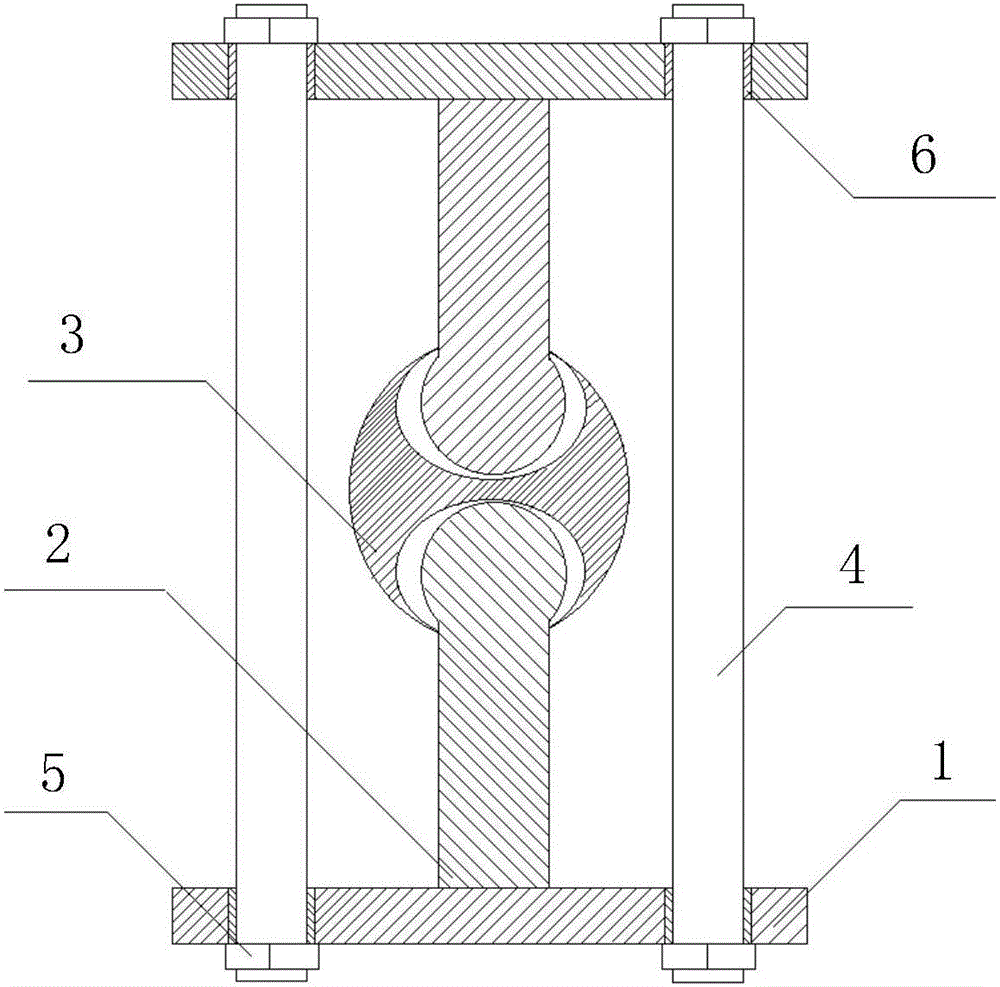

[0029] see figure 1 and figure 2 , figure 1 It is a top view of the connecting device of the ultra-large floating structure module based on flexible rods in the present invention, figure 2 It is a front sectional view of the present invention along the plane where its axis is located. As shown in the figure, a connection device for a super-large floating structure module based on flexible rods, including: two bases 1, two spherical hinge rods 2, spherical hinge supports 3, multiple flexible rods 4, A plurality of connecting nuts 5 and a plurality of adjusting washers 6;

[0030] One ends of the two spherical hinge rods 2 are respectively fixed on the inner surfaces of the two bases 1, and the other ends are respectively connected by the spherical hinge supports 3, and the two spherical hinge rods The angle between 2 is 180 degrees, and the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com