Slat tilting detection device of aircraft high lift system

A technology of tilt detection and slats, applied in aircraft parts, ground installations, transportation and packaging, etc., can solve the problems of lack of mature products and early R&D applications, and achieve the effect of ensuring reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

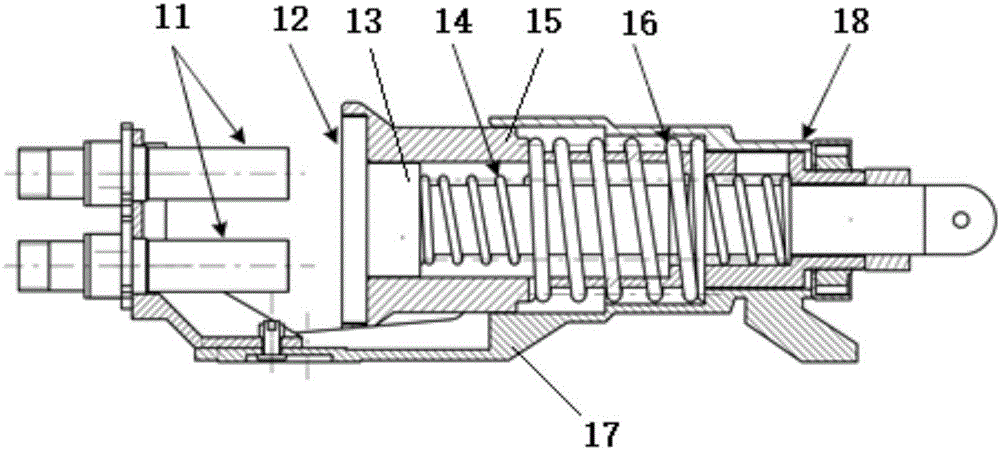

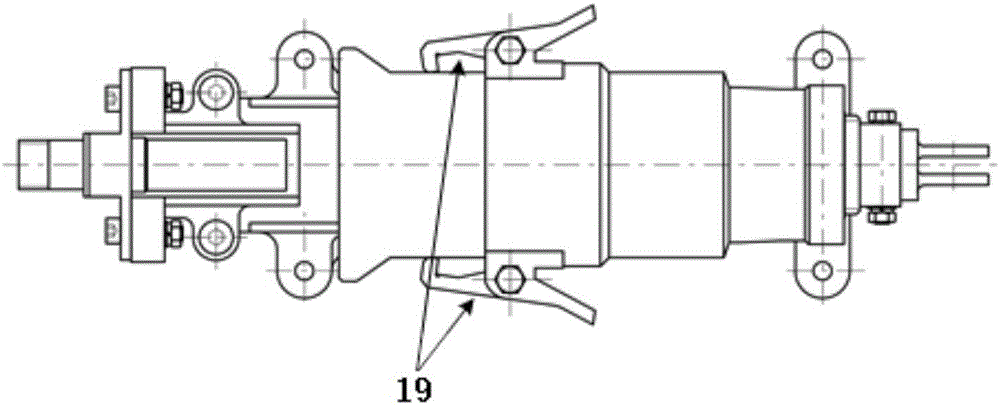

[0025] The invention relates to a slat tilt detection device for a high-lift system of an aircraft, which can realize the detection of the inconsistency of the movement of adjacent airfoil surfaces of a plurality of side-by-side slats, and transmit the detected signal to the flight control system; ensure that the steel cables are under tension state and self-compensation for the length change of the cable under high and low temperature, wing deformation, etc.; the mechanism itself realizes self-locking; tension limit protection.

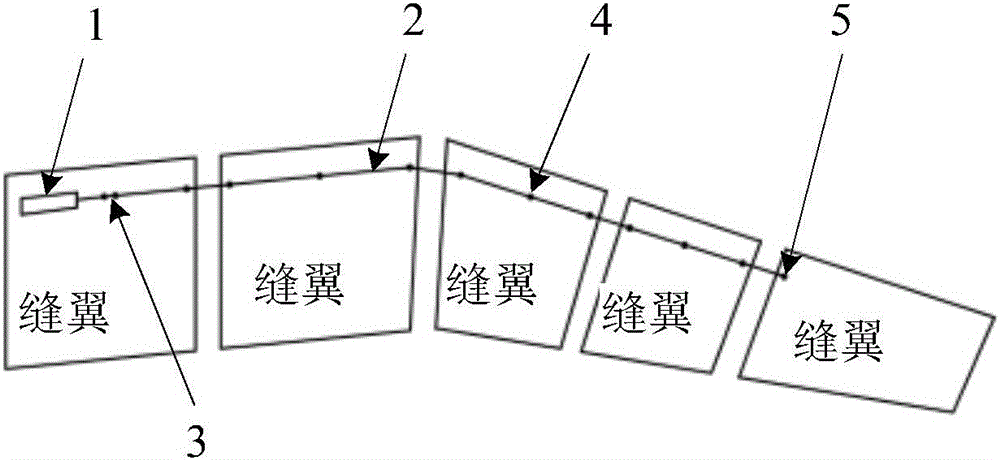

[0026] Such as figure 1 As shown, it includes a slat tilt detection sensor 1 and a steel cable 2; wherein, the steel cable 2 is arranged through a plurality of side-by-side slats in sequence, one end is fixed to the outermost slat, and the other end passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com