Novel molecular sieve filling machine

A molecular sieve and filling machine technology, used in packaging, large containers, transportation and packaging, etc., can solve the problems of manual duty, inaccurate control, and molecular sieve particle rupture and differentiation, and achieve the effect of preventing moisture regain, ensuring quality, and convenient testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

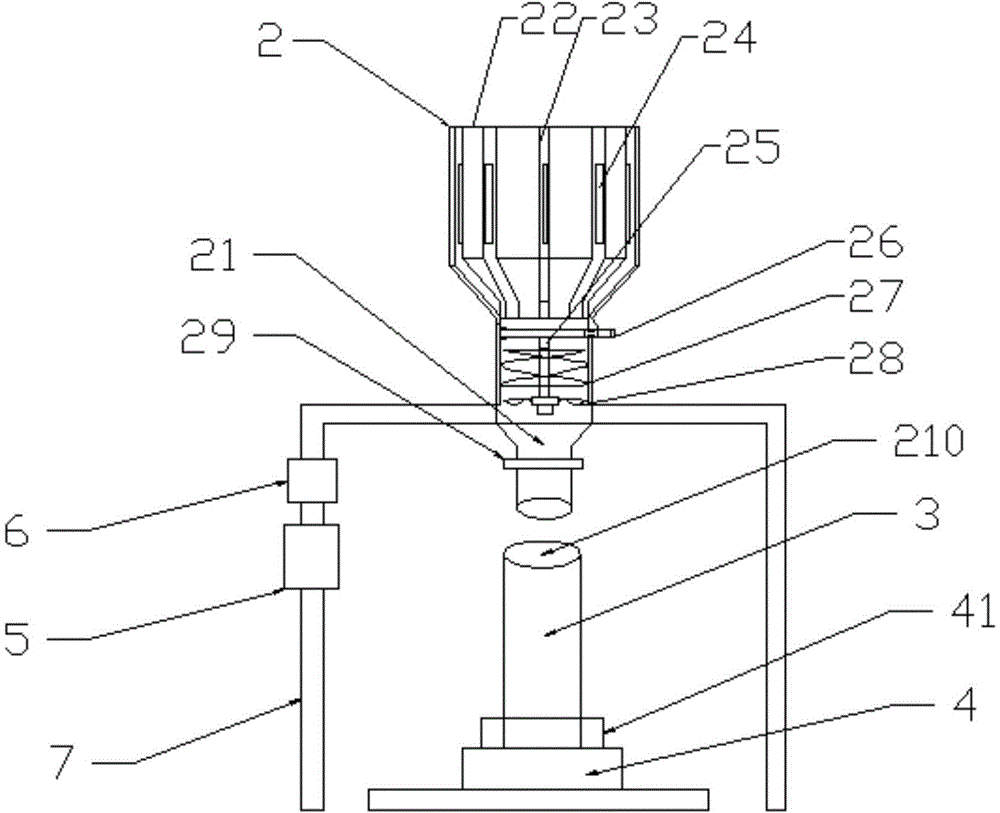

[0012] see figure 1 , a new molecular sieve filling machine, including a feeding device 2, a fixed bracket 7, a receiving bucket 3, a vibrating table 4 and an electrical control box 5, the fixed bracket 7 is a U-shaped bracket with an opening downward, and the feeding device 2 is fixedly arranged On the crossbar of the fixed support 7, the vibrating table 4 is arranged below the feeding device 2, the receiving bucket 3 is arranged on the vibrating table 4, a gap is provided between the vibrating table 4 and the fixed support 7, and the vibrating table 4 is provided with The vibration motor, the electric control box 5 is electrically connected with the vibration motor. During the material receiving process, the vibration motor vibrates, driving the vibration table 4 to vibrate, and the molecular sieve particles in the material receiving bucket 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com