A Quick Hook Mechanism for Tile Packaging Line

A packaging line, fast technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of large space occupation, long action cycle, incompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In conjunction with the above-mentioned accompanying drawings, the present invention is described in further detail:

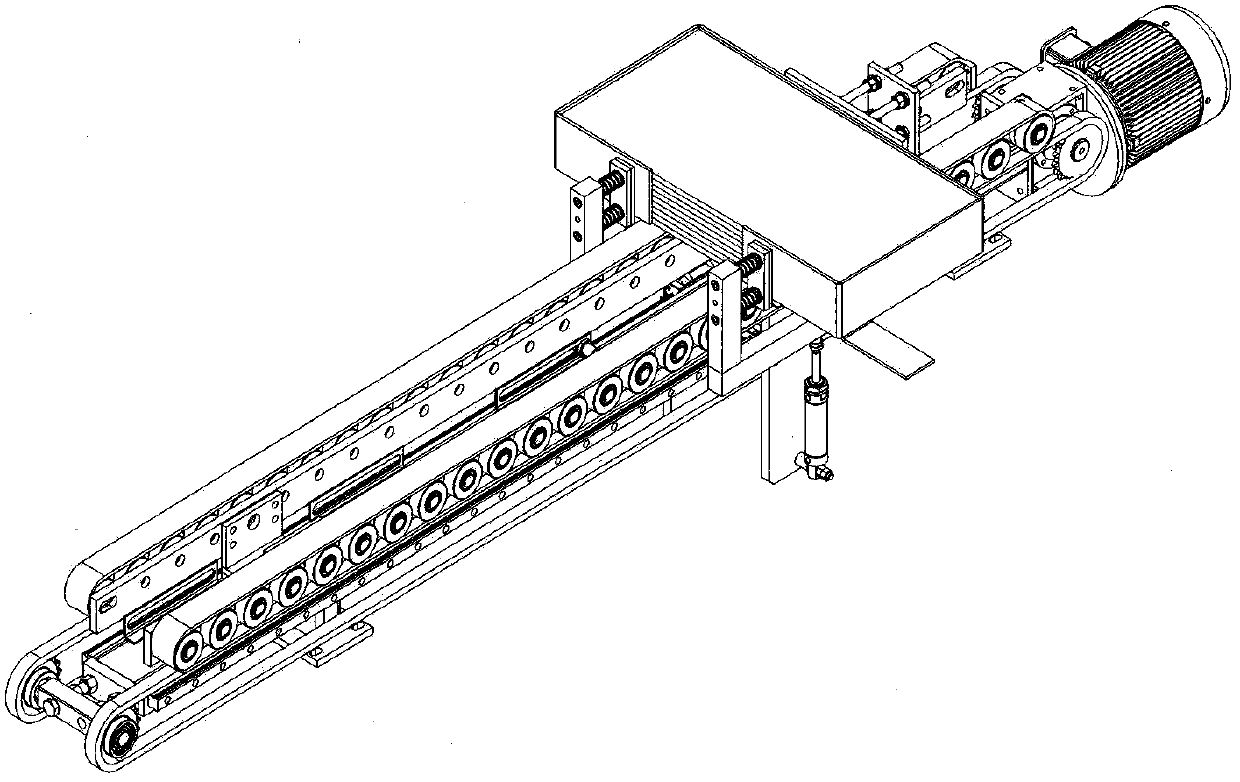

[0013] The present invention is a fast hook feeding mechanism for ceramic tile packaging line, which includes support frame assembly 1, reduction motor 2, driving wheel assembly 3, chain 4, limit plate assembly 5, unpowered conveyor belt assembly 6, and linear guide rail pair 7. The slider seat assembly 8, the air cylinder 9, the hook feeding assembly 10, and the driven wheel assembly 11.

[0014] The support frame assembly 1 is horizontally connected to the frame at the center, the geared motor 2 is fixed on the output end of the support frame assembly 1, and the driving wheel assembly 3 is centered and symmetrically set in the output hole of the geared motor 2, wherein the driving wheel assembly 3 includes two pieces The driving sprocket is respectively fixed at both ends of the driving wheel assembly 3, the driven wheel assembly 11 is fixed at the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com