Automatic box packing machine

An automatic cartoning machine and rack technology, applied in packaging and other directions, can solve the problems of low efficiency, inability to meet the production needs of various specifications of the box body of the enterprise, and the lack of adaptability of boxes of different specifications, so as to improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] To facilitate understanding, the present invention will be further described below in conjunction with the accompanying drawings.

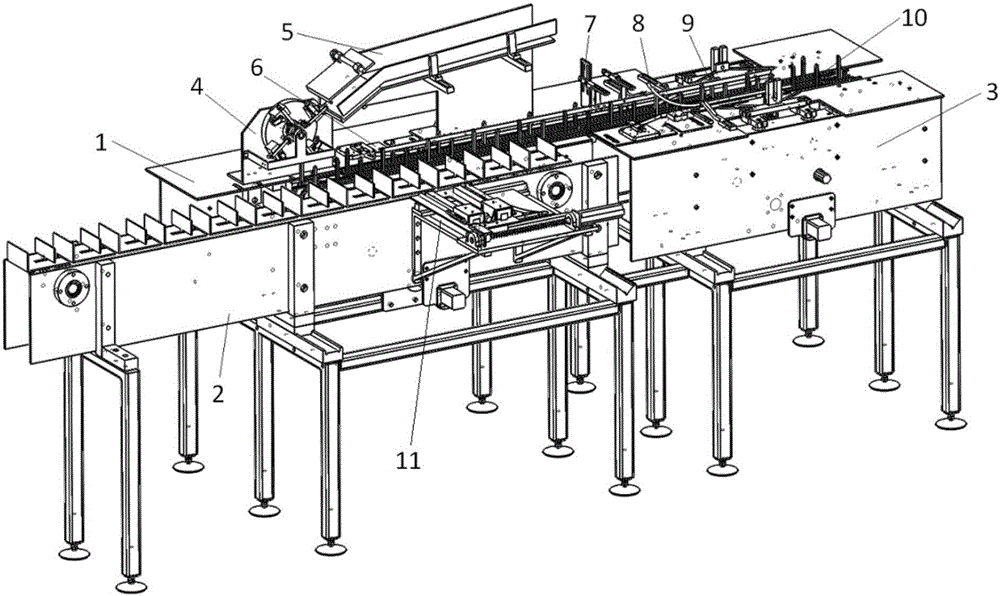

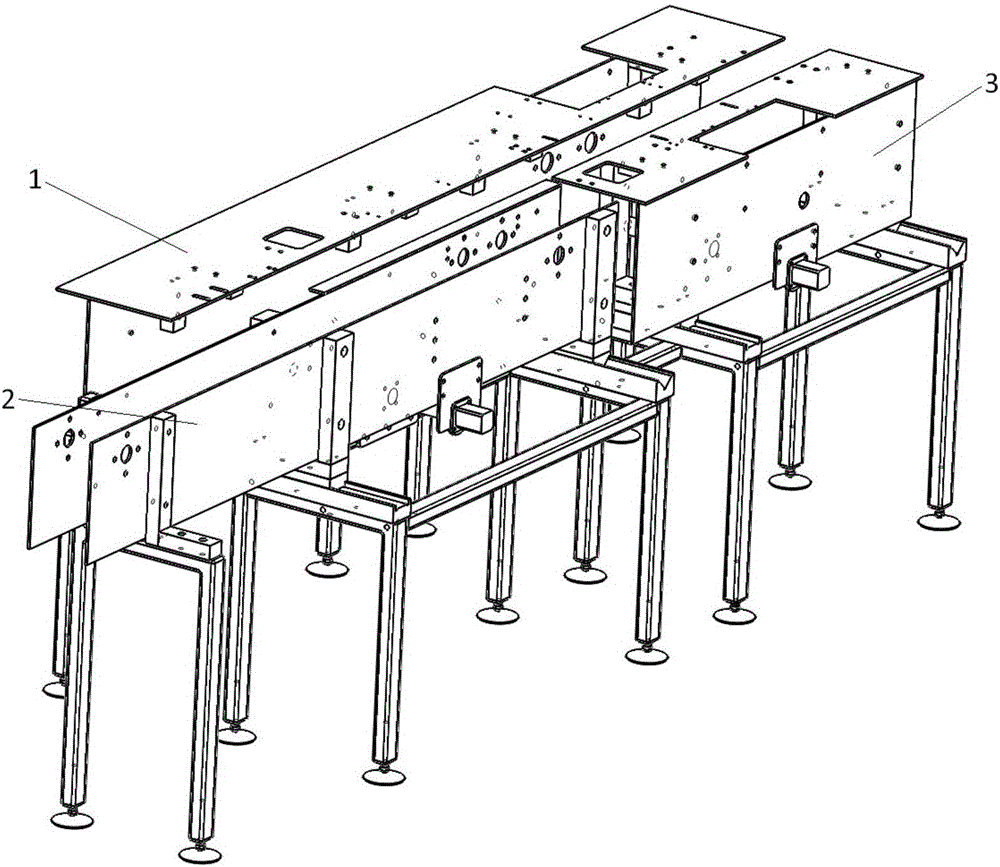

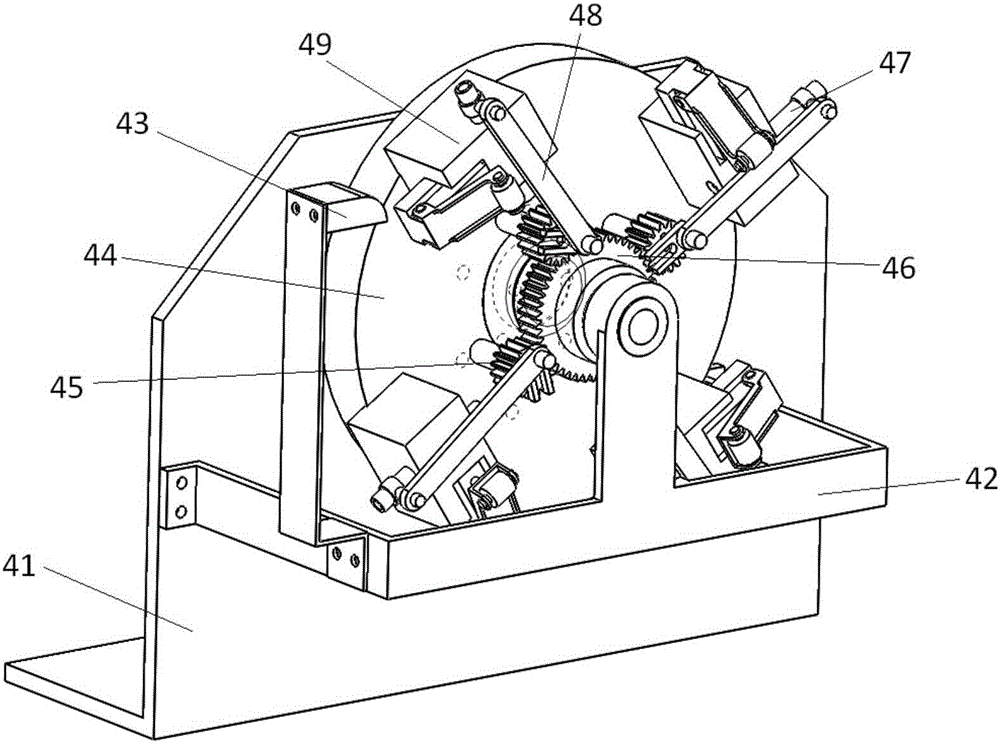

[0029] See Figure 1~Figure 8 , figure 1 Is a schematic structural diagram of an automatic cartoning machine provided by an embodiment of the present invention; figure 2 Yes figure 1 The layout diagram of middle piece 1, piece 2 and piece 3; image 3 Yes figure 1 Schematic diagram of middleware 4; Figure 4 Yes image 3 Section view of Figure 5 Yes figure 1 The structure diagram of Middleware 11; Image 6 Yes Figure 5 Show picture of middle structure 116; Figure 7 Yes Figure 5 Section A-A in Figure 8 Yes figure 1 Schematic diagram of the middle part 6.

[0030] An automatic cartoning machine provided by an embodiment of the present invention includes a first frame 1, a second frame 2, and a box feeding mechanism 10 located between the first frame 1 and the second frame 2.

[0031] Among them, the first frame 1 is provided with a box supply r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap