Vacuum bucket elevator

A bucket elevator, bucket elevator technology, applied in the direction of conveyor, transportation and packaging, can solve the problem that the gas tightness of ordinary bucket elevator can not be reached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

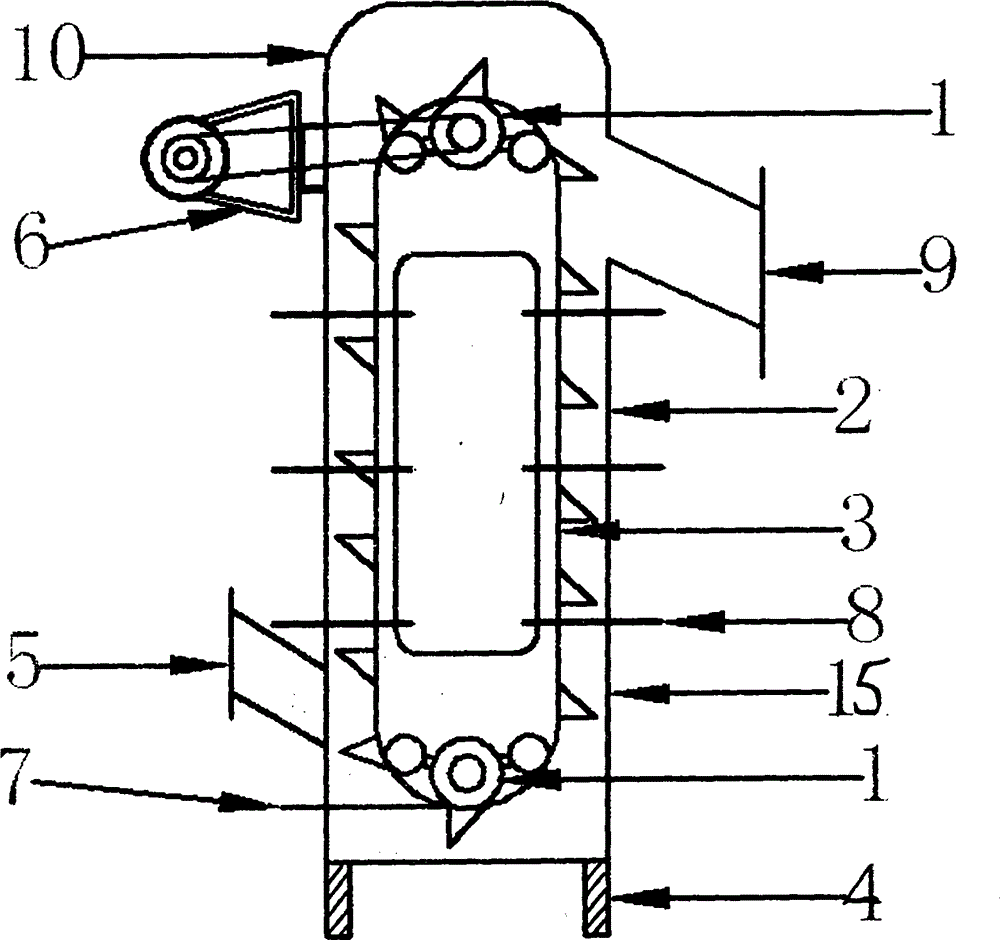

[0033] Such as figure 1 Shown: a vacuum bucket elevator consists of an upper casing (10), a lower casing (15), a casing (2), a support (4) and a bucket lifting device (3).

[0034] Described upper casing (10) and lower casing (15) are connected and fixed by multi-section casing (2) shell; Upper casing (10) is above, and lower casing (15) is below, and casing ( 2) In the middle of the upper casing (10) and the lower casing (15); the bucket lifting device (3) is installed inside the upper casing (10), the lower casing (15) and the chassis casing (2).

[0035] There are flanges at both ends of the chassis shell (2), and sealing rings are arranged on the flanges.

[0036] The shape of the case shell (2) is cylindrical; the flange on the case shell (2) is a circular flange made of steel plate.

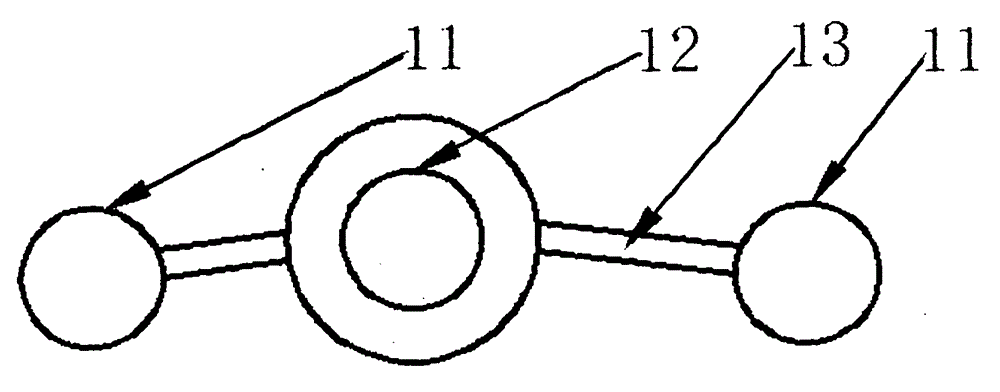

[0037] The bucket lifting device (3) is composed of a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com