Special-shaped electrochromic glass capable of being driven in time-sharing mode

An electrochromic glass and time-sharing drive technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of uneven discoloration of electrochromic glass, high effective driving voltage, and insufficient effective driving voltage in the middle, and achieve improvement The effect of the distribution of the effective driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

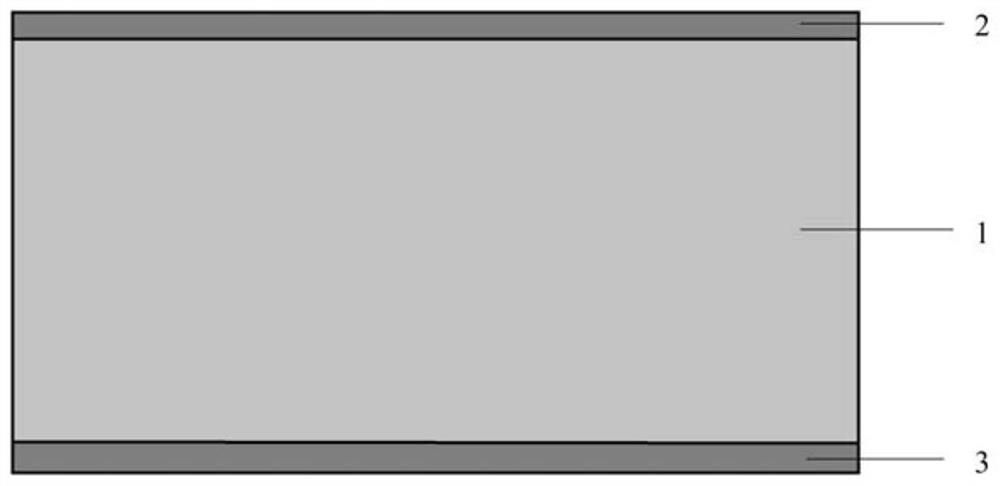

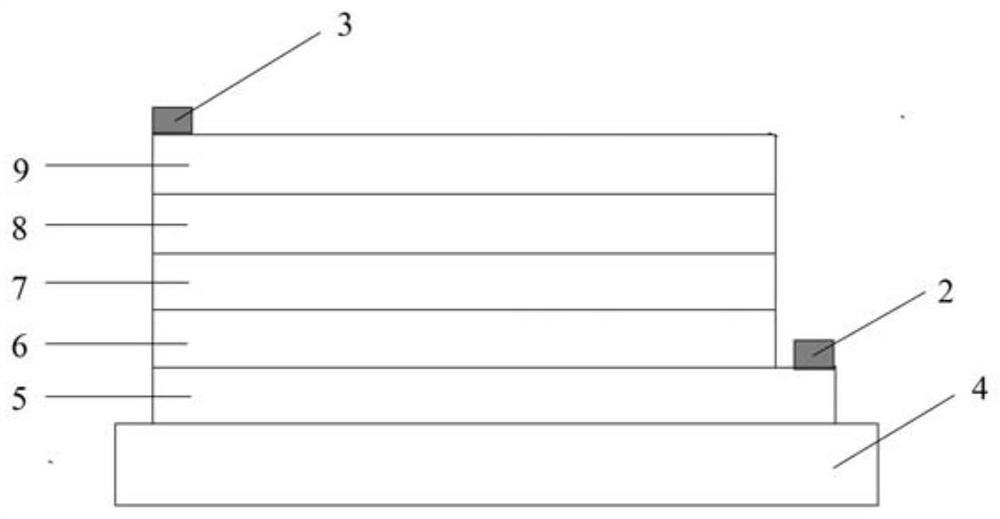

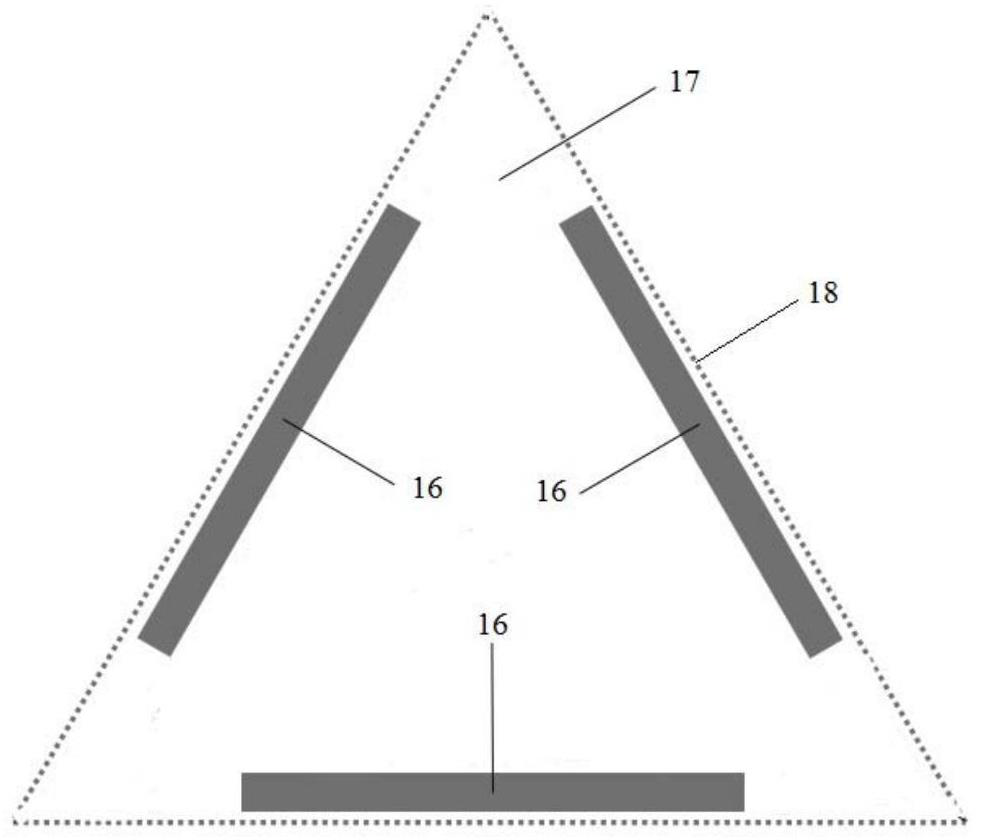

[0041] The invention provides a special-shaped electrochromic glass that can be driven in time division, such as figure 1 and 2 Shown is a rectangular electrochromic device 1, using the rectangular electrochromic device 1 to briefly illustrate the preparation process and film layer structure of the special-shaped electrochromic glass; prepare the first conductive layer 5 on the substrate, and Prepare the first electrochromic layer 6 on the first conductive layer 5 and leave a vacancy for the bottom electrode, prepare the ion conductive layer 7 on the first electrochromic layer 6, the second electrochromic layer 8 and the second conductive layer 9 . The first electrochromic layer 6 , the ion conducting layer 7 , the second electrochromic layer 8 and the second conducting layer 9 have the same width. A strip-shaped bottom electrode 2 is prepared on the vacancy of the first conductive layer 5 , and a strip-shaped top electrode 3 is arranged on the edge of the second conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com