Stop valve and hydrogen-oxygen recombination system

A shut-off valve and valve body technology, which is applied in the field of hydrogen-oxygen recombination system, can solve the problem that the stop valve cannot meet the requirements of the hydrogen-oxygen recombination system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

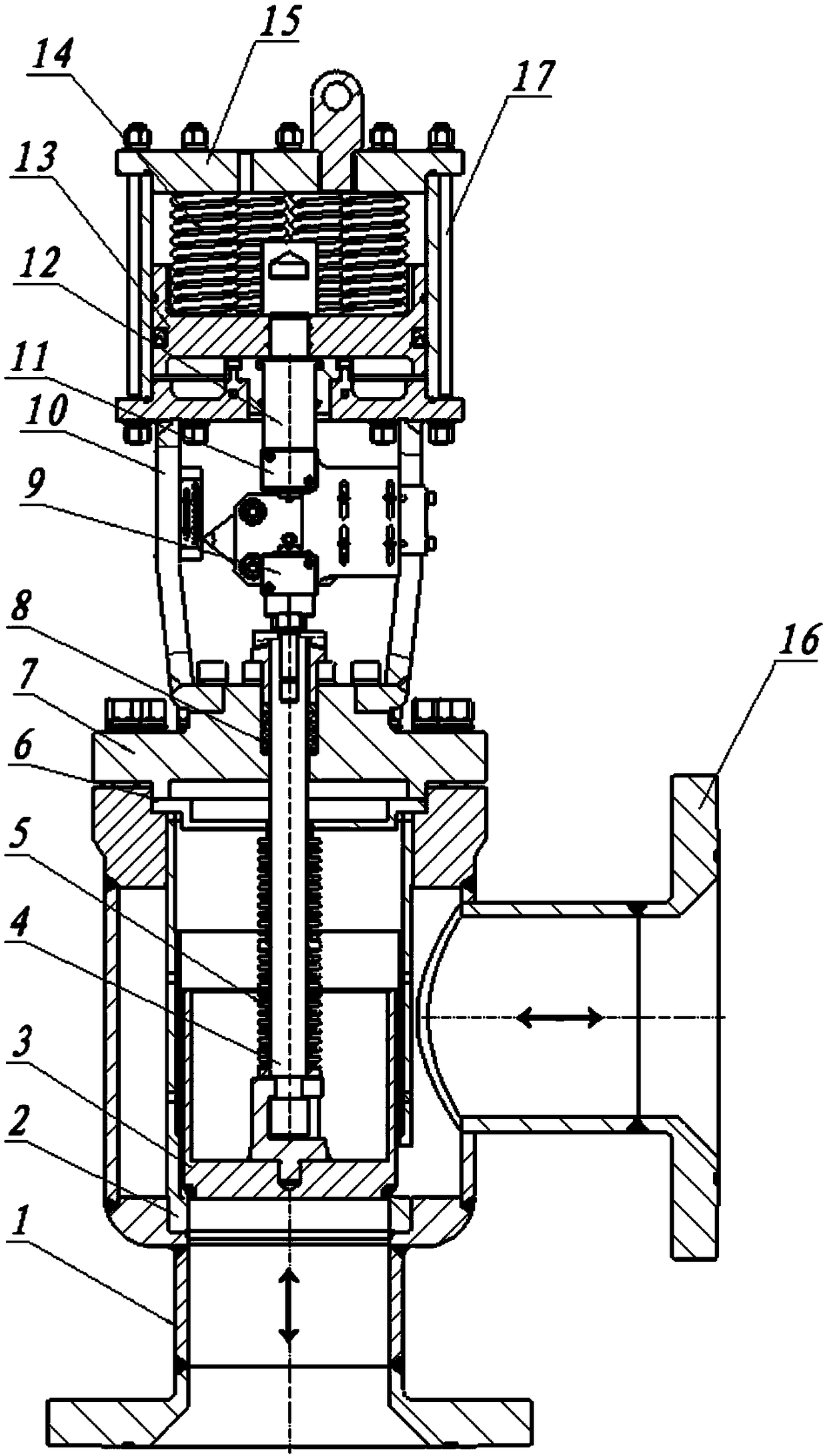

[0040] The stop valve provided by the present invention, such as Figure 1 to Figure 2 As shown, it includes a valve body component, a sealing component and an executive component; the valve body component includes a valve seat 2, a valve cover 7, a first valve body 1, a second valve body 16, a valve disc 3 and a valve stem 4; the valve seat 2 has The first cavity, the first opening, the second opening, and the third opening; the valve cover 7 is fixed on the valve seat 2 to close the first opening; the first valve body 1 communicates with the second opening, and the second valve body 16 Connected with the third opening; the valve flap 3 is connected with the valve stem 4, the valve flap 3 is arranged in the first cavity, and the end of the valve stem 4 away from the valve flap 3 extends out of the valve cover 7; the actuator is connected with the valve stem 4 for Drive the valve flap 3 toward or away from the second opening to close or open the second opening; the sealing assem...

Embodiment 2

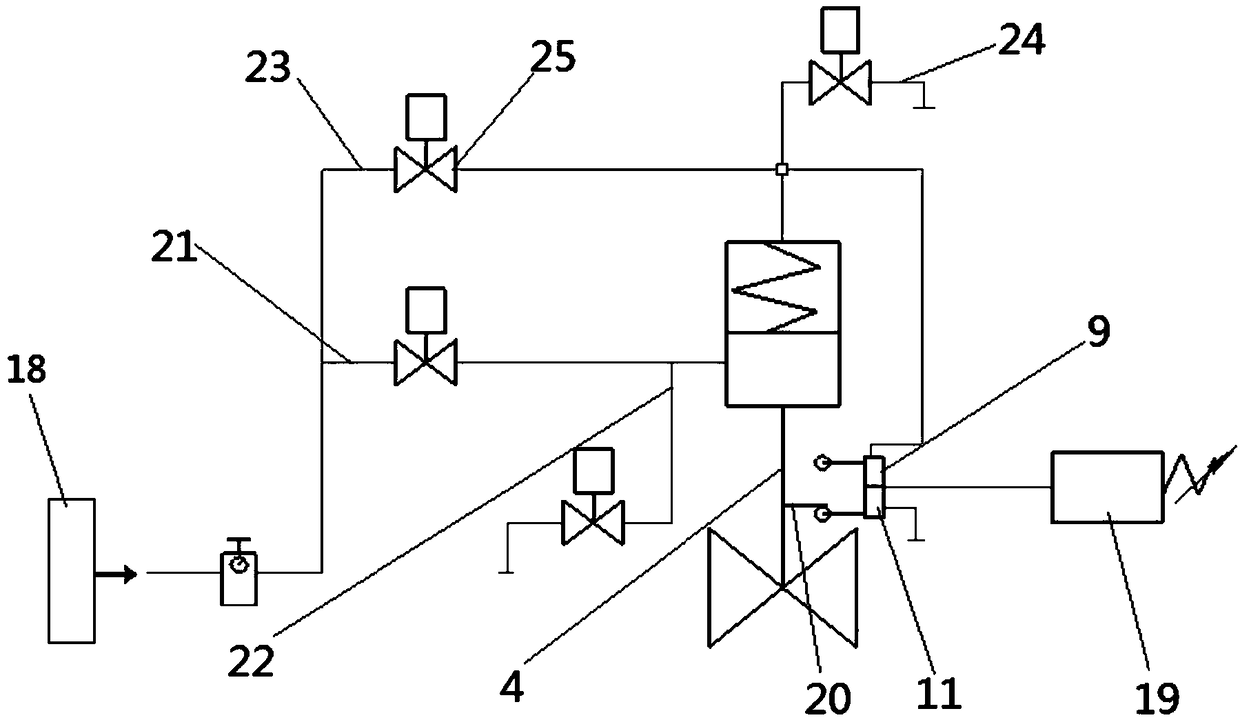

[0086] The hydrogen-oxygen recombination system provided in this embodiment includes the shut-off valve described in Embodiment 1. When the valve flap 3 moves away from the second opening, the second opening is opened and the medium flows into the first cavity. Because the bellows 5 can be compressed and abut the valve cover 7, it can seal the valve stem 4 and the valve cover 7. The gap between the valve cover 7 and the valve seat 2 is provided with a gasket 6 to seal the gap between the valve cover 7 and the valve seat 2. In addition, the packing 8 can seal the valve stem 4 and the valve cover 7 again The gap between them can reduce the leakage of the medium, and the gasket 6 and the bellows 5 are made of radioactive shielding materials, which can control the leakage of radioactive materials to the outside, so as to meet the requirements of the hydrogen-oxygen recombination system. Run safely and smoothly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com