A smart card positioning device

A positioning device and smart card technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of easy deviation, card offset, and large card position deviation, so as to ensure normal production and processing and simple structure , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

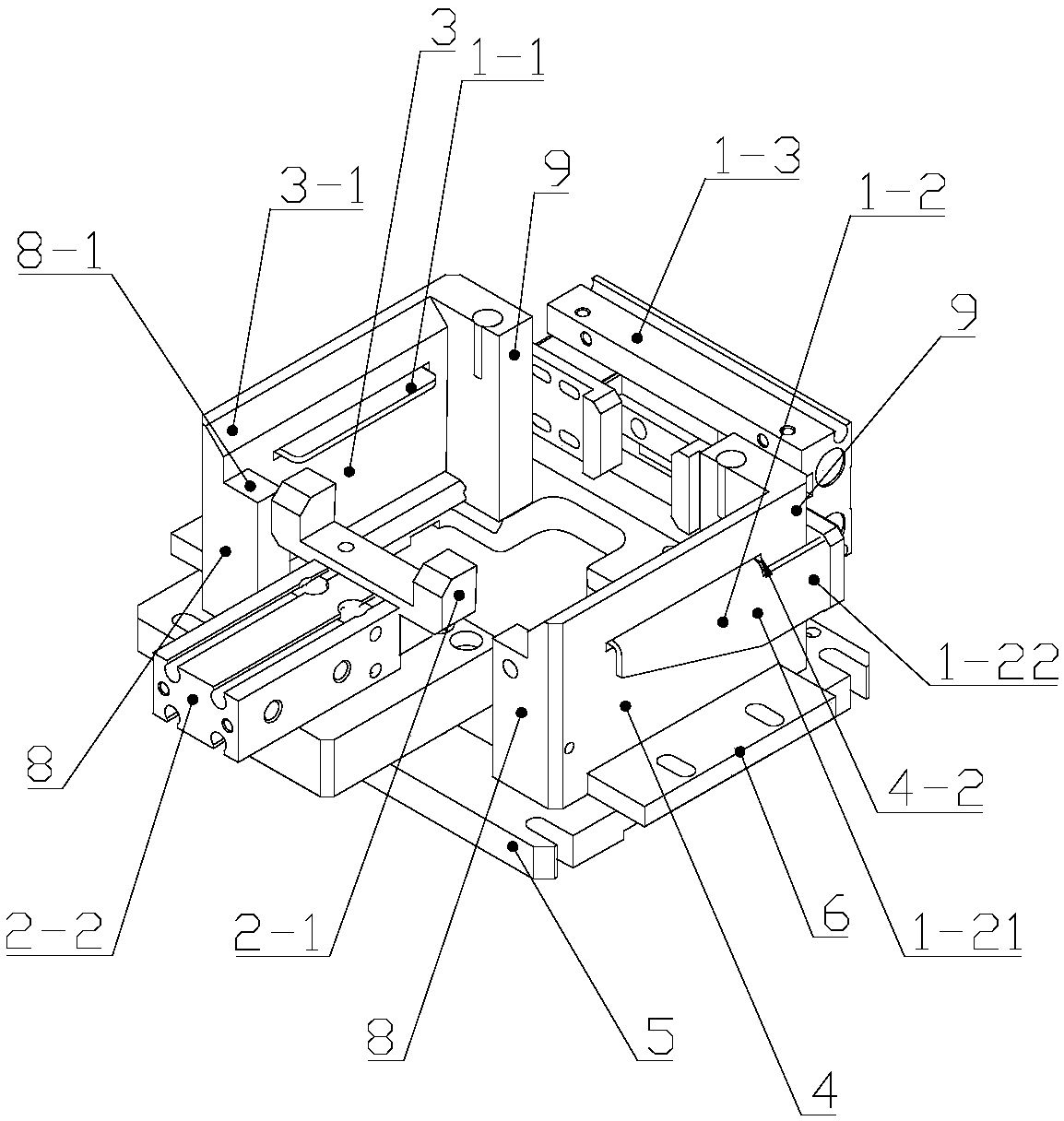

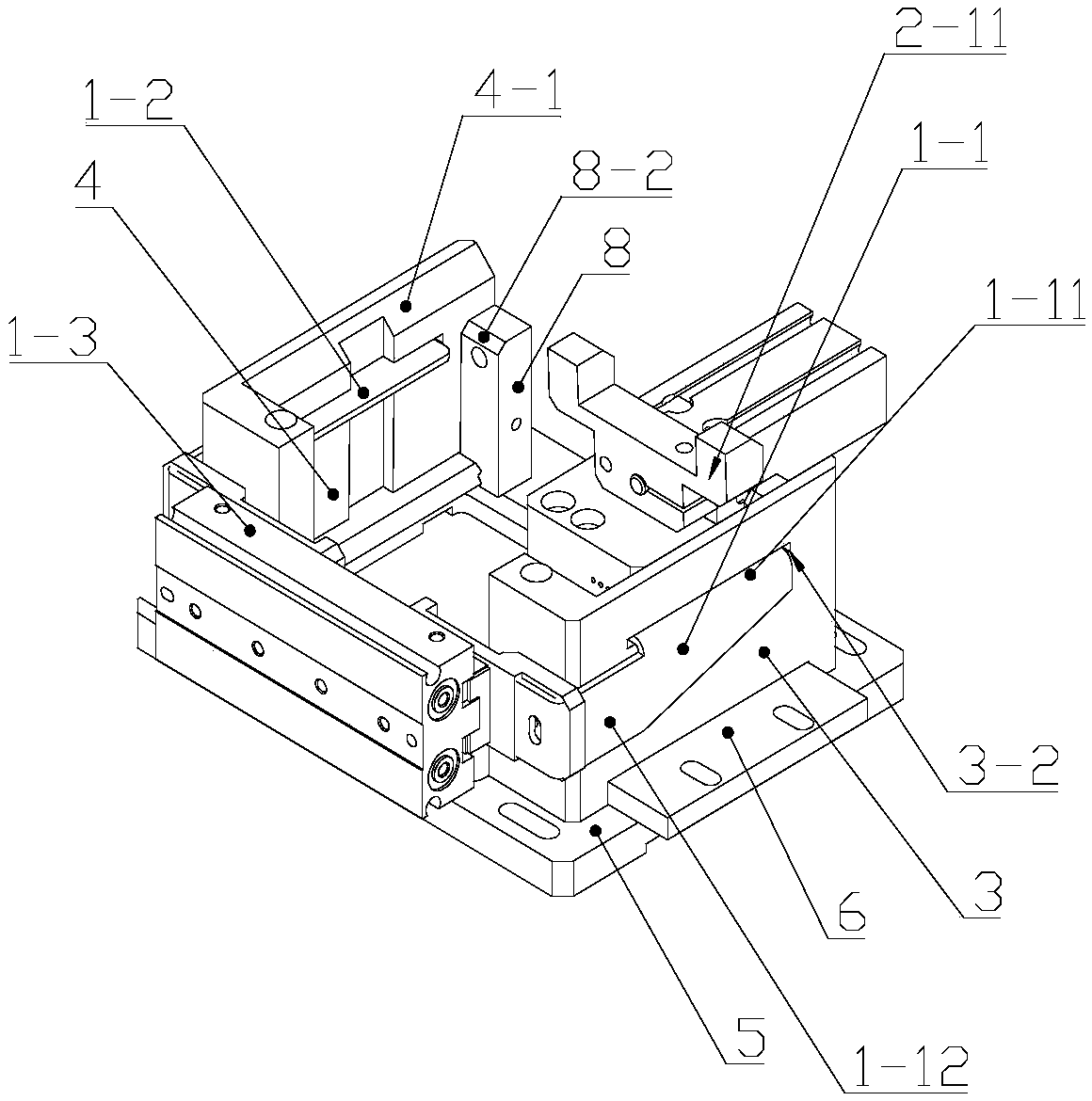

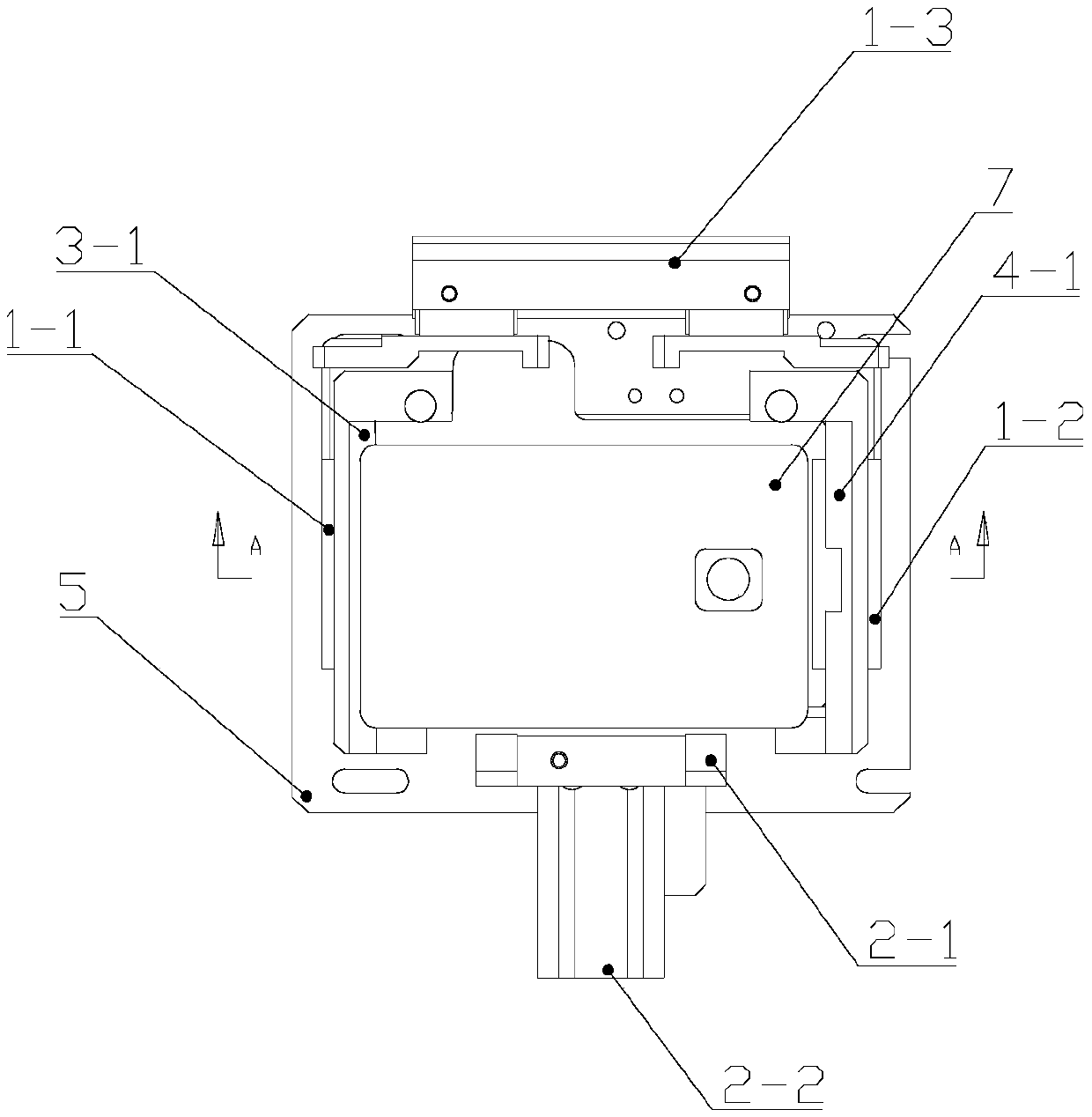

[0035] see figure 1 and figure 2, the smart card positioning device includes a positioning box, a card blocking mechanism and a card pushing mechanism; wherein, the size of the cross-section of the cavity of the positioning box matches the size of the smart card, and the positioning box includes two pairs of positioning plates opposed to each other ; wherein, the first positioning plate 3 in the first pair of positioning plates is provided with a first guide surface 3-1 and a second guide surface 4-1 on the top surface of the second positioning plate 4, the first The guide surface 3-1 and the second guide surface 4-1 are combined together to form a guide opening gradually enlarged from bottom to top; the stopper mechanism includes a first stopper 1-1, a second stopper 1-2 and a The first baffle 1-1 and the second baffle 1-2 make a first drive device 1-3 that reciprocates toward each other; a first notch 3-2 is provided below the first guide surface 3-1, so that The first ba...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] see Figure 10 , the first driving device 1-3 is composed of a first cylinder 1-31 and a second cylinder 1-32; wherein, the first cylinder 1-31 drives the first baffle plate 1-1 to reciprocate, and the second cylinder drives the second gear The plate 1-2 reciprocates, and the synchronous control is used to meet the requirement for synchronization when the first baffle 1-1 and the second baffle 1-2 move.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] see Figure 11 , the positioning box is made up of four positioning plates, which are respectively the first positioning plate 3 in the first pair of positioning plates, the second positioning plate 4 in the first pair of positioning plates, and the second positioning plate in the second pair of positioning plates. One positioning plate 8, the second positioning plate 9 in the second pair of positioning plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com