Paper pulp preparation method

A pulp and pulp technology, which is applied to non-woody plant/crop pulp, paper, textiles and papermaking, etc., can solve the problems of single raw material, consumption, production demand and production cost cannot be guaranteed, save wood, ensure Overall texture, loss-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

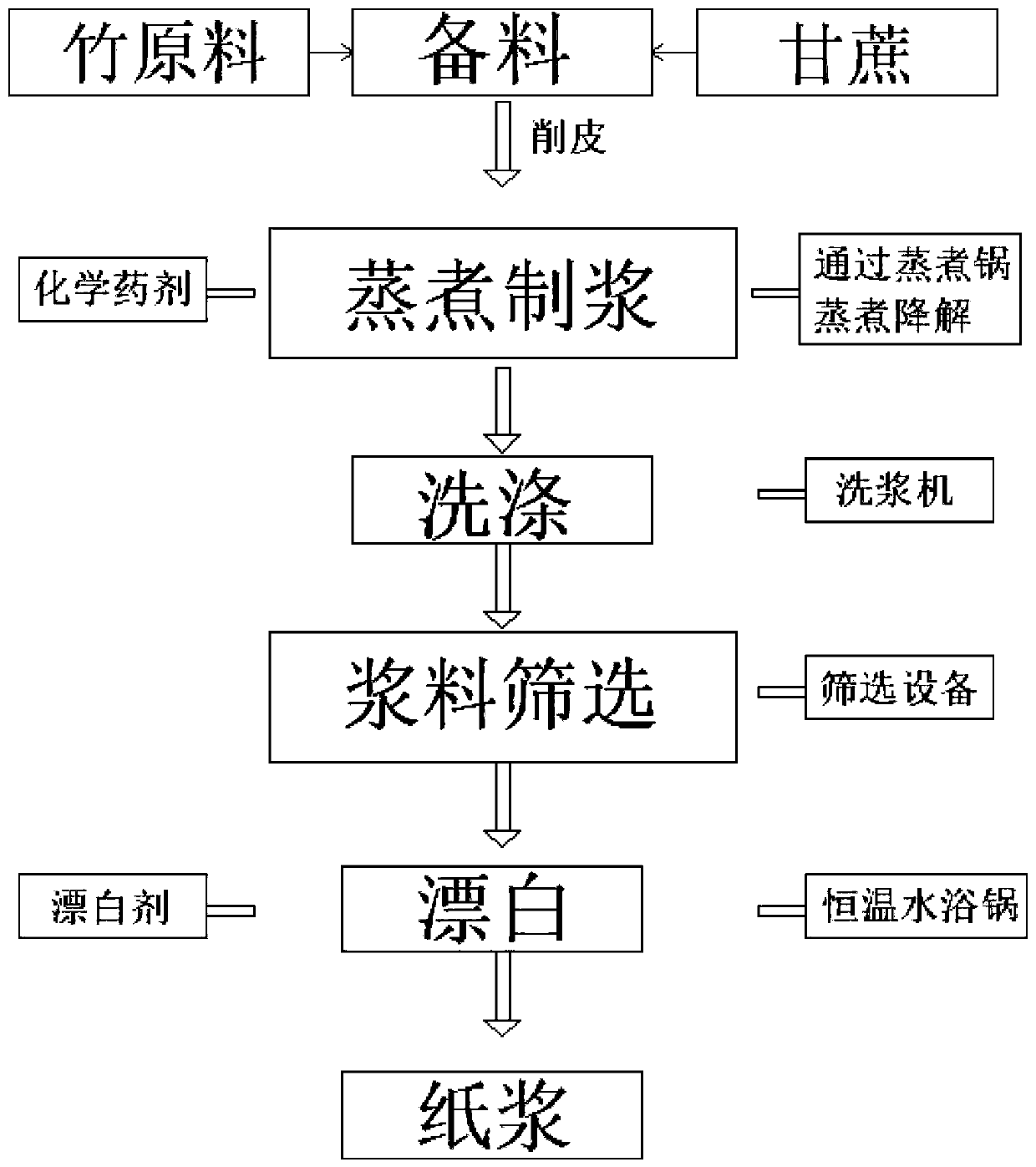

[0022] see figure 1 , the embodiment that the present invention provides: a kind of paper pulp preparation method, adopt bamboo raw material and sugarcane as raw material, and carry out the preparation of paper pulp by equipment operations such as peeling machine, cooker, pulp washing machine, screening equipment, constant temperature water bath, It is characterized in that: comprising the following five steps:

[0023] Step 1: be 50-70% bamboo raw material and 30-50% sugarcane to carry out material preparation operation with weight ratio, and carry out peeling processing to bamboo raw material and sugarcane by peeling machine; The peeling operation of peeling machine is to make follow-up The cooking process can be better carried out;

[0024] Step 2: Put the peeled bamboo raw materials and sugarcane into the cooking pot, and cook and degrade them to produce crude pulp; before 100°C, the concentration of the cooking liquid decreases, but the lignin basically does not dissolve...

Embodiment 2

[0033] 1. Beating

[0034] 1. Use physical and mechanical methods to process the pulp, and the operation can be completed through a disc refiner, so that the fibers are separated into single fibers by extrusion, friction, kneading, shearing, etc.

[0035] 2. The role of beating

[0036] (1) Displace and deform the cell wall;

[0037] (2) breaking the outer layer (S) of the primary wall (P) and the secondary wall;

[0038] (3) fine fibrillation (separation of fibrillation-fiber ends and fiber surface microfibers are scattered and fluffy);

[0039] The purpose of its operation is to increase the contact area between fibers and enhance the interweaving force between fibers.

[0040] Two, sizing

[0041] Sizing refers to adding water-resistant sizing agent to the pulp or applying sizing on the surface of the paper web to make the paper obtain

[0042] Ability to resist diffusion and penetration of liquids.

[0043] The purpose of sizing is to change the surface energy of fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com