Supporting platform for crane

A technology for supporting platforms and cranes, applied in the directions of load hanging elements, safety devices, transportation and packaging, etc., can solve the problem of uneven force, and achieve the effects of preventing overturning accidents, safe and stable transportation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

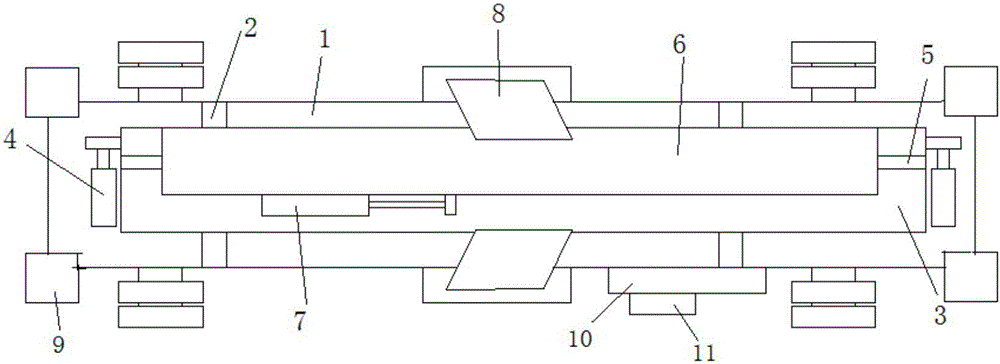

[0010] Referring to the accompanying drawings, a support platform for a crane includes an auxiliary vehicle girder 1, two rails 2 are installed on the upper surface of the auxiliary vehicle girder 1, and a support platform 3 is slidably installed on the rail 2, and the support platform 3 The front and rear ends are respectively connected with a cylinder 4, the cylinder 4 can control the front and rear movement of the support platform 3, the surface of the support platform 3 is provided with a transverse track 5, and a transverse adjustment plate is slidably installed on the transverse track 5 6. A horizontal cylinder 7 is connected to the side wall of the horizontal adjustment plate 6, and the horizontal adjustment plate 7 can move left and right under the control of the horizontal cylinder 7. Each corner of the auxiliary vehicle frame 1 is equipped with a hydraulic cylinder 9. A level sensor 10 is provided on the side wall of the sub-vehicle frame 1, and the level sensor 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com