Ultra-low double girder crane with large used space

A double-girder crane, ultra-low technology, applied in cranes, walking bridge cranes, transportation and packaging, etc. The effect of improved space, prevention of wheel rails, and low overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

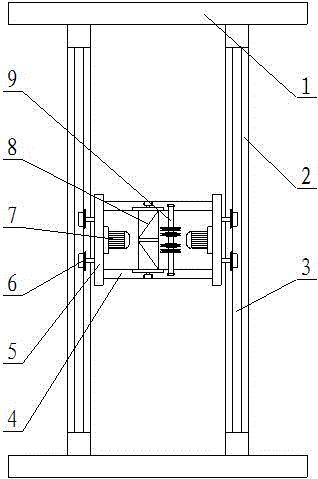

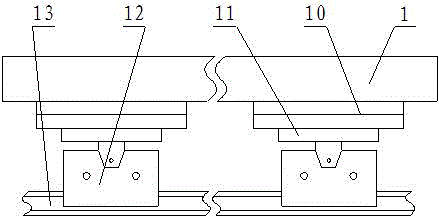

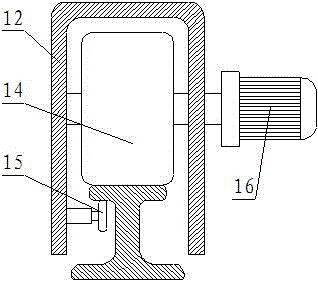

[0019] Such as figure 1 — Figure 5 Shown, a kind of ultra-low double-girder crane with large use space, it comprises end beam 1, the position near two ends on the lower surface of described end beam 1 is provided with lifting platform 10, the lower surface of described lifting platform 10 The wheel frame 12 is connected to the rotating table 11, the wheel frame 12 is provided with a traveling wheel 14, the driving device A16 is connected to the traveling wheel 14, and the traveling wheel 14 is arranged on the I-shaped cart guide rail On the upper step surface of 13, a support wheel 15 is arranged under the traveling wheel 14 on the wheel frame 12, and the support wheel 15 is arranged on the lower surface of the upper step surface of the cart guide rail 13, and the end beam The inner surface of 1 is connected with two main beams 2 parallel to each other. The main beam 2 adopts a "凵"-shaped structure, and the upper surface of the main beam 2 is provided with a trolley walking ...

Embodiment 2

[0022] Such as figure 1 — Figure 5 Shown, a kind of ultra-low double-girder crane with large use space, it comprises end beam 1, the position near two ends on the lower surface of described end beam 1 is provided with lifting platform 10, the lower surface of described lifting platform 10 The wheel frame 12 is connected to the rotating table 11, the wheel frame 12 is provided with a traveling wheel 14, the driving device A16 is connected to the traveling wheel 14, and the traveling wheel 14 is arranged on the I-shaped cart guide rail On the upper step surface of 13, a support wheel 15 is arranged under the traveling wheel 14 on the wheel frame 12, and the support wheel 15 is arranged on the lower surface of the upper step surface of the cart guide rail 13, and the end beam The inner surface of 1 is connected with two main beams 2 parallel to each other. The main beam 2 adopts a "凵"-shaped structure, and the upper surface of the main beam 2 is provided with a trolley walking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com