Method for oxidizing Shengli lignite with alkali-oxygen at low temperature

A Shengli lignite and low-temperature technology, applied in the field of coal chemical industry, can solve the problems of application restrictions, production, storage, utilization, transportation restrictions, etc., and achieve the effect of reducing spontaneous combustion tendency, significant economic and social benefits, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

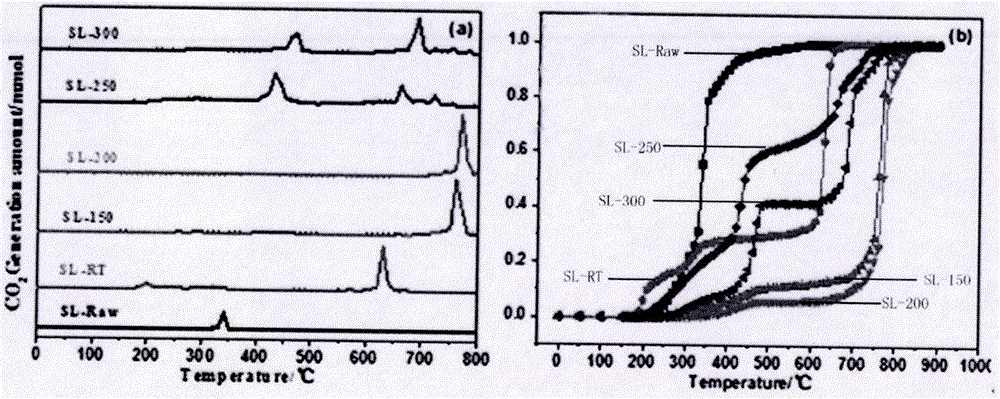

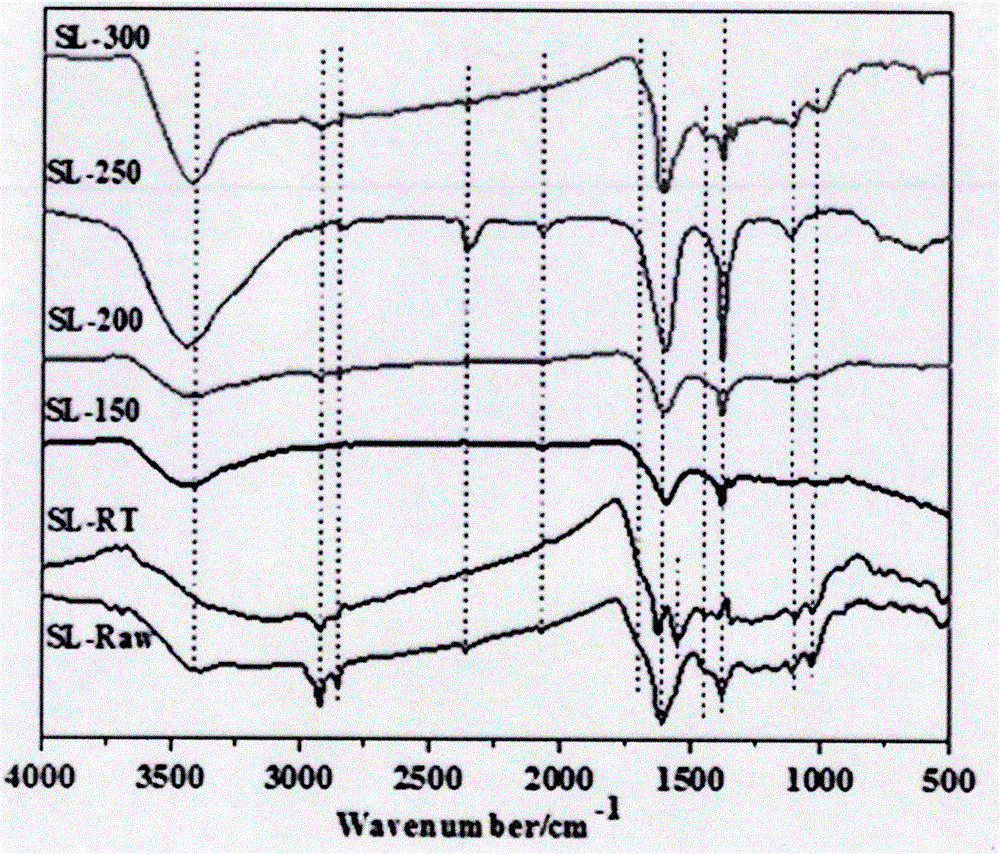

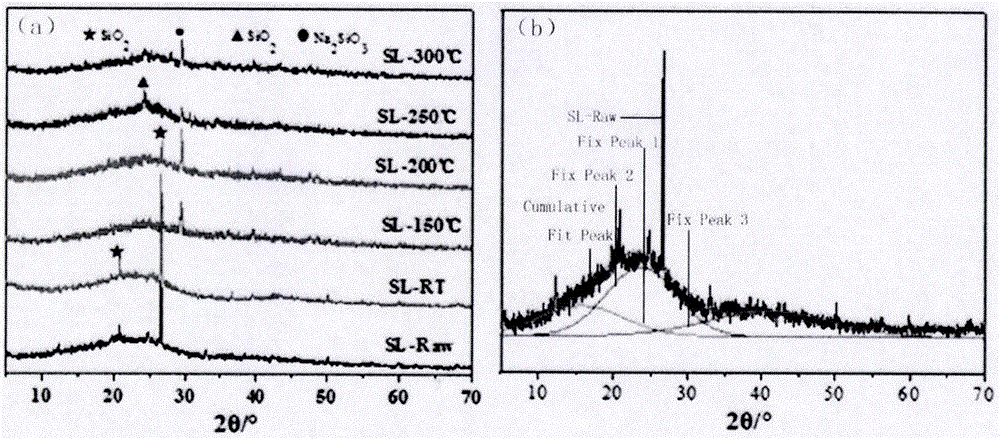

[0022] A method for alkali-oxygen low-temperature oxidation of Shengli lignite, prepared by the following steps:

[0023] 1) Grinding coal to 80-100 mesh, drying at 105°C for 4 hours to obtain coal powder;

[0024] 2) Add coal powder and 0.5mol / L NaOH solution into the autoclave, seal the autoclave, pass oxygen to 0.6MPa, raise the temperature from room temperature to 150°C at a speed of 300r / min, and keep the temperature at the final temperature for 1h. After cooling to room temperature, the sample was obtained;

[0025] 3) Suction filter the sample, wash the filter residue with distilled water until pH = 8, and then dry it at 105°C for 4 hours to obtain 150°C alkali-oxygen low-temperature oxidation Shengli lignite, which is designated as SL-150.

[0026] The coal is the Shengli lignite from the Xilingol area of Inner Mongolia.

[0027] The mass ratio of the coal powder and NaOH solution is 1:4.

[0028] The heating time is 1h.

Embodiment 2

[0030] A method for alkali-oxygen low-temperature oxidation of Shengli lignite, prepared by the following steps:

[0031] 1) Grinding coal to 80-100 mesh, drying at 105°C for 4 hours to obtain coal powder;

[0032] 2) Put coal powder and 0.5mol / L NaOH solution into the autoclave, seal the autoclave, pass oxygen to 0.6MPa, raise the temperature from room temperature to 200°C at a speed of 300r / min, and keep the temperature at the final temperature for 1h. After cooling to room temperature, the sample was obtained;

[0033] 3) The sample was suction-filtered, and the filter residue was washed with distilled water until pH = 8, and then dried at 105°C for 4 hours to obtain 200°C alkali-oxygen low-temperature oxidation Shengli lignite, which was designated as SL-200.

[0034] The coal is the Shengli lignite from the Xilingol area of Inner Mongolia.

[0035] The mass ratio of the coal powder and NaOH solution is 1:5.

[0036] The heating time is 1h.

Embodiment 3

[0038] A method for alkali-oxygen low-temperature oxidation of Shengli lignite, prepared by the following steps:

[0039] 1) Grinding coal to 80-100 mesh, drying at 105°C for 4 hours to obtain coal powder;

[0040] 2) Add coal powder and 0.5mol / L NaOH solution into the autoclave, seal the autoclave, pass oxygen to 0.6MPa, raise the temperature from room temperature to 250°C at a speed of 300r / min, and keep the temperature at the final temperature for 1h. After cooling to room temperature, the sample was obtained;

[0041] 3) The sample was suction-filtered, and the filter residue was washed with distilled water until pH = 8, and then dried at 105°C for 4 hours to obtain 250°C alkali-oxygen low-temperature oxidation Shengli lignite, which was designated as SL-250.

[0042] The coal is the Shengli lignite from the Xilingol area of Inner Mongolia.

[0043] The mass ratio of the coal powder and NaOH solution is 1:5.

[0044] The heating time is 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com