Materialized synergistic coal inhibitor and preparation method thereof

A chemical inhibitor and coal technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of gas emission hazards, low resistance efficiency, incomplete resistance, etc., to prevent heat transfer and spontaneous combustion tendency The effect of reducing and obtaining materials is convenient and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

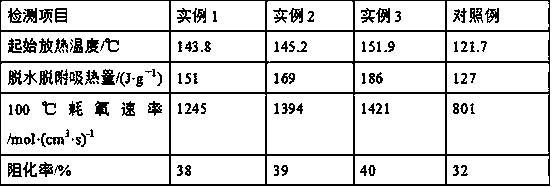

Examples

example 1

[0022] Get 13.6g of zinc chloride, 19.0g of magnesium chloride, 13.3g of aluminum chloride, add 2L of deionized water, stir at 300r / min for 30min, then add 1.0g of lanthanum chloride, and use a mass fraction of 10% sodium carbonate solution to adjust the pH to 10. Stir at 500r / min for 1 hour, put it into a hydrothermal reaction kettle, keep it warm at 70°C for 15 hours, cool to room temperature and filter to get the filter residue, wash the filter residue with deionized water until the washing liquid is neutral, then place the filter residue in In a drying oven, dry at 70°C to constant weight to obtain rare earth hydrotalcites. Take 20g of rare earth hydrotalcites, add them to 300mL of deionized water, disperse them with 300W ultrasonic waves for 20min, then add 2g of antioxidant 1010, 1g of anti-oxidant Oxygen agent 168, stirred at 300r / min for 20min, then evaporated to dryness under reduced pressure, then transferred to a mortar for grinding, passed through a 60-mesh sieve to...

example 2

[0024] Get 20.4g zinc chloride, 28.6g magnesium chloride, 20.0g aluminum chloride, add 3L deionized water, stir with 400r / min for 35min, then add 1.5g lanthanum chloride, and use the mass fraction as 10% sodium carbonate solution to adjust the pH to 10. Stir at 500r / min for 1 hour, put it into a hydrothermal reaction kettle, keep it warm at 75°C for 18 hours, cool to room temperature and filter to get the filter residue, wash the filter residue with deionized water until the washing liquid is neutral, and then place the filter residue in In a drying oven, dry at 75°C to constant weight to obtain rare earth hydrotalcites. Take 25g of rare earth hydrotalcites, add them to 300mL of deionized water, disperse them with 300W ultrasonic waves for 25min, then add 2g of antioxidant 1010, 1g of anti-oxidant Oxygen agent 168, stirred at 300r / min for 25min, then evaporated to dryness under reduced pressure, then transferred to a mortar for grinding, passed through a 60-mesh sieve to obtain...

example 3

[0026] Get 20.4g zinc chloride, 28.6g magnesium chloride, 20.0g aluminum chloride, add 3L deionized water, stir 40min with 400r / min, then add 2.5g lanthanum chloride, and use mass fraction as 10% sodium carbonate solution to adjust the pH to 11. Stir at 600r / min for 2h, put it into a hydrothermal reaction kettle, keep it warm at 80°C for 20h, cool to room temperature and filter to get the filter residue, wash the filter residue with deionized water until the washing liquid is neutral, and then place the filter residue in In a drying oven, dry at 80°C to constant weight to obtain rare earth hydrotalcites. Take 30g of rare earth hydrotalcites, add them to 400mL of deionized water, disperse them with 300W ultrasonic waves for 30min, then add 3g of antioxidant 1010, 2g of anti-oxidant Oxygen agent 168, stirred at 400r / min for 30min, evaporated to dryness under reduced pressure, then transferred to a mortar and ground, passed through a 60-mesh sieve to obtain oxygen barrier powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com