Patents

Literature

33results about How to "Reduce the possibility of spontaneous combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation

ActiveCN104762097AReduce coal dust contentImprove qualitySpecial form destructive distillationGranularityCoal dust

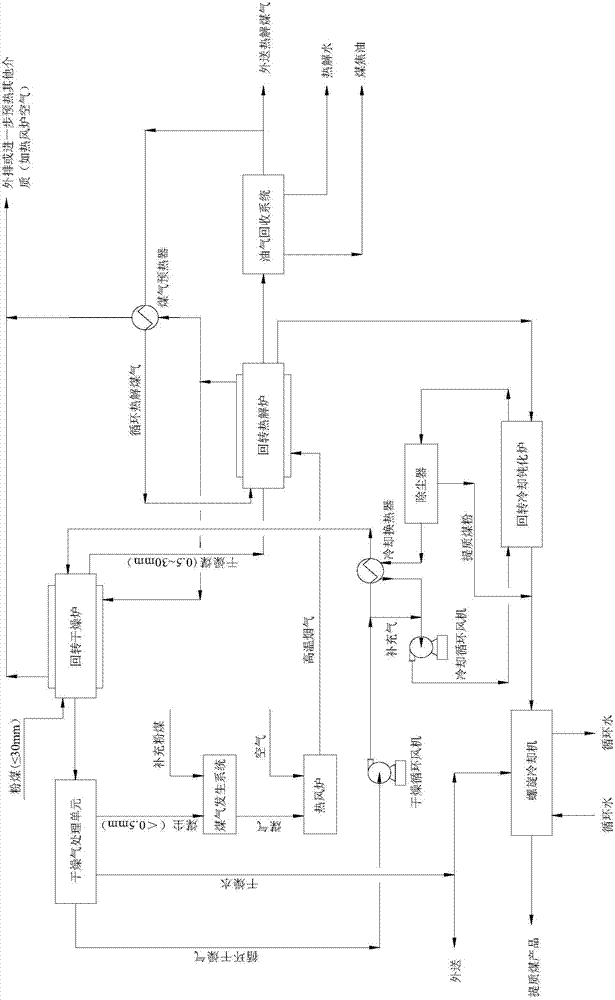

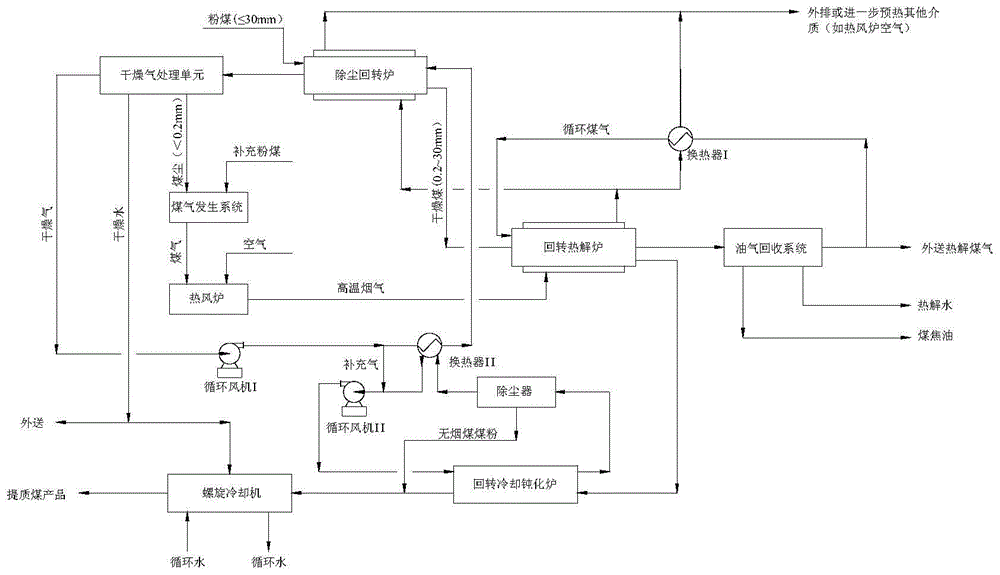

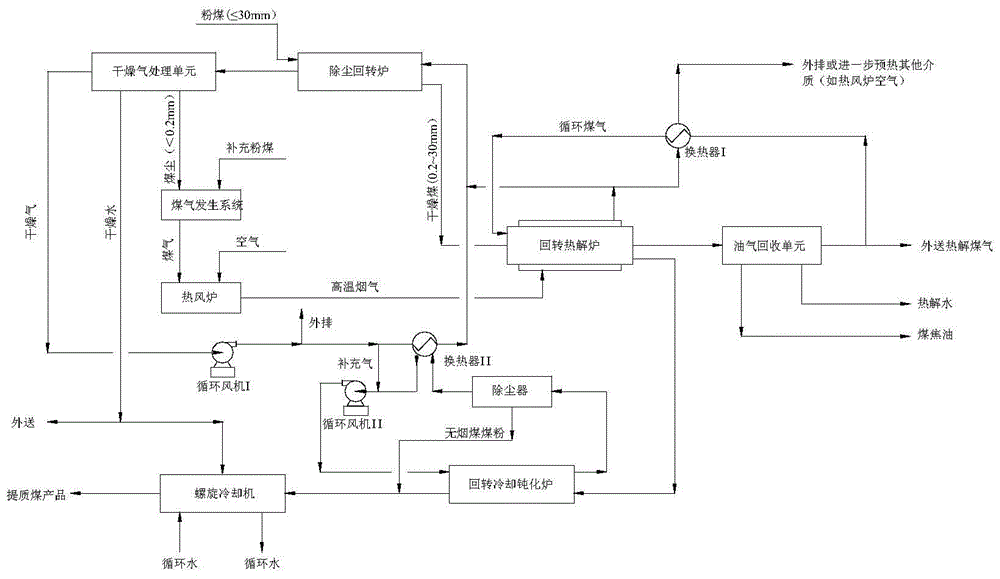

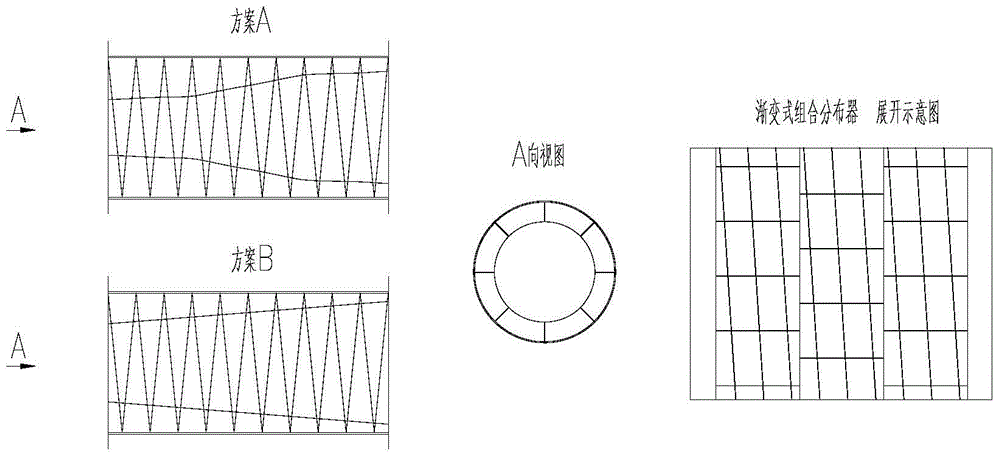

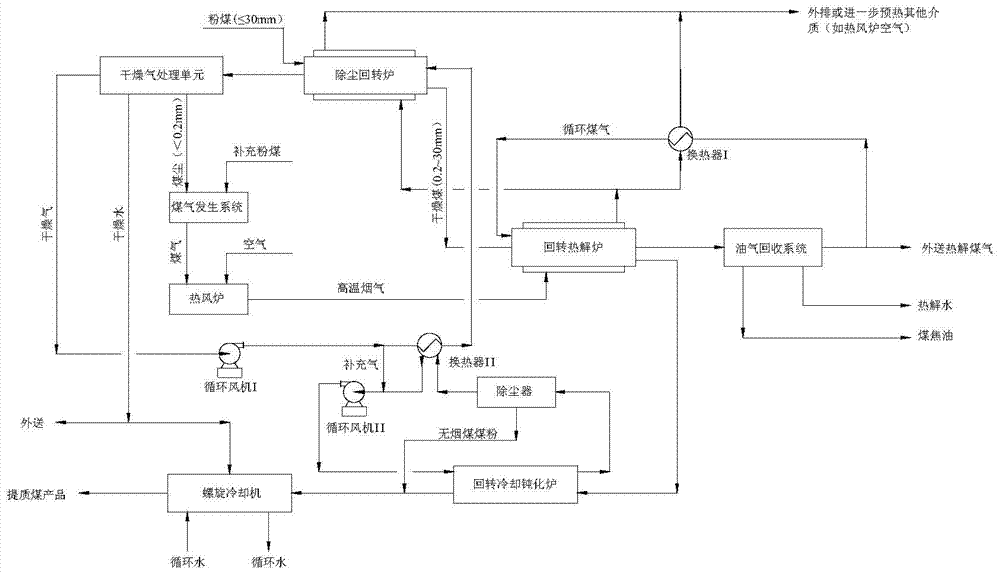

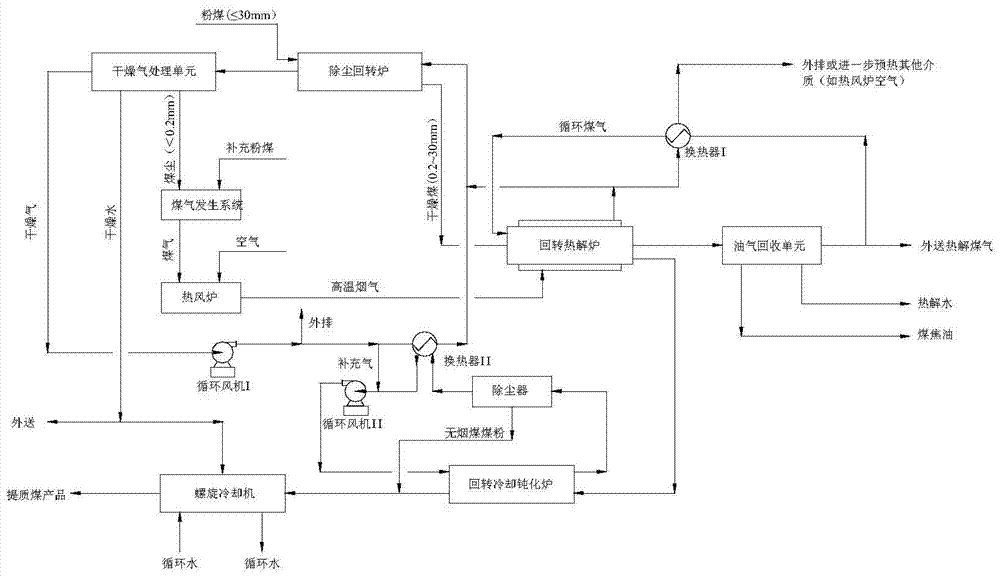

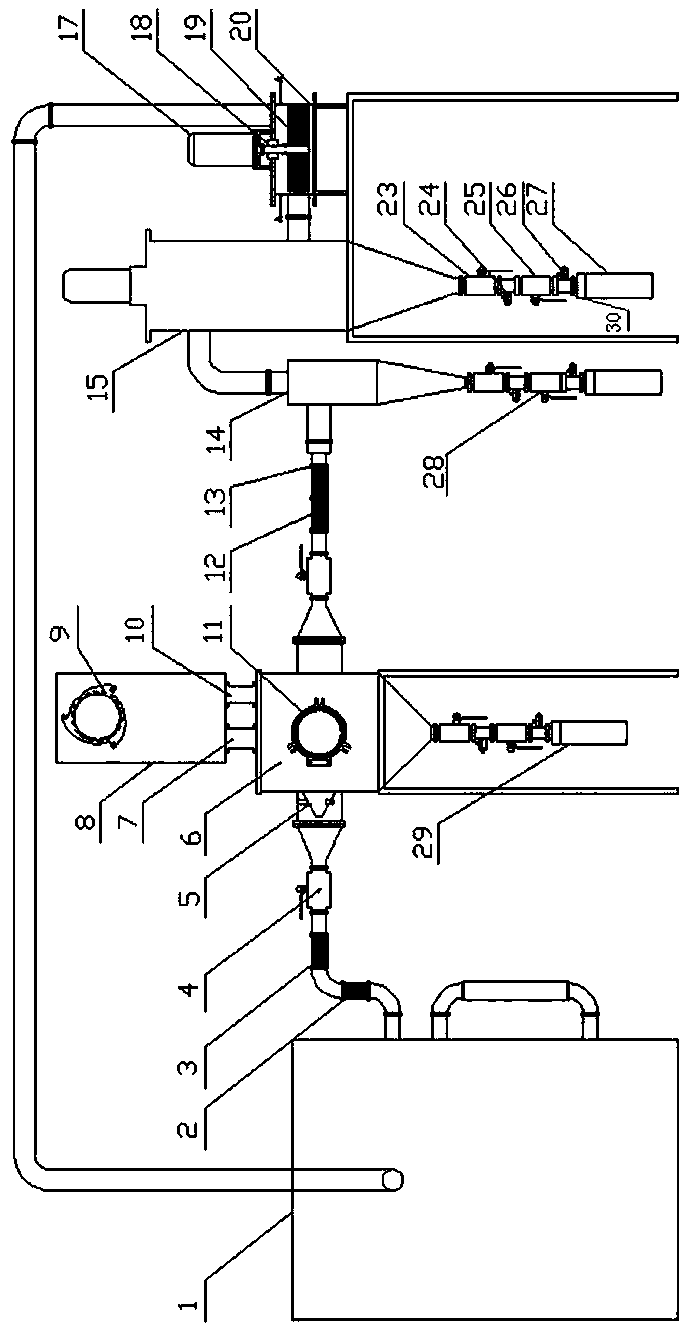

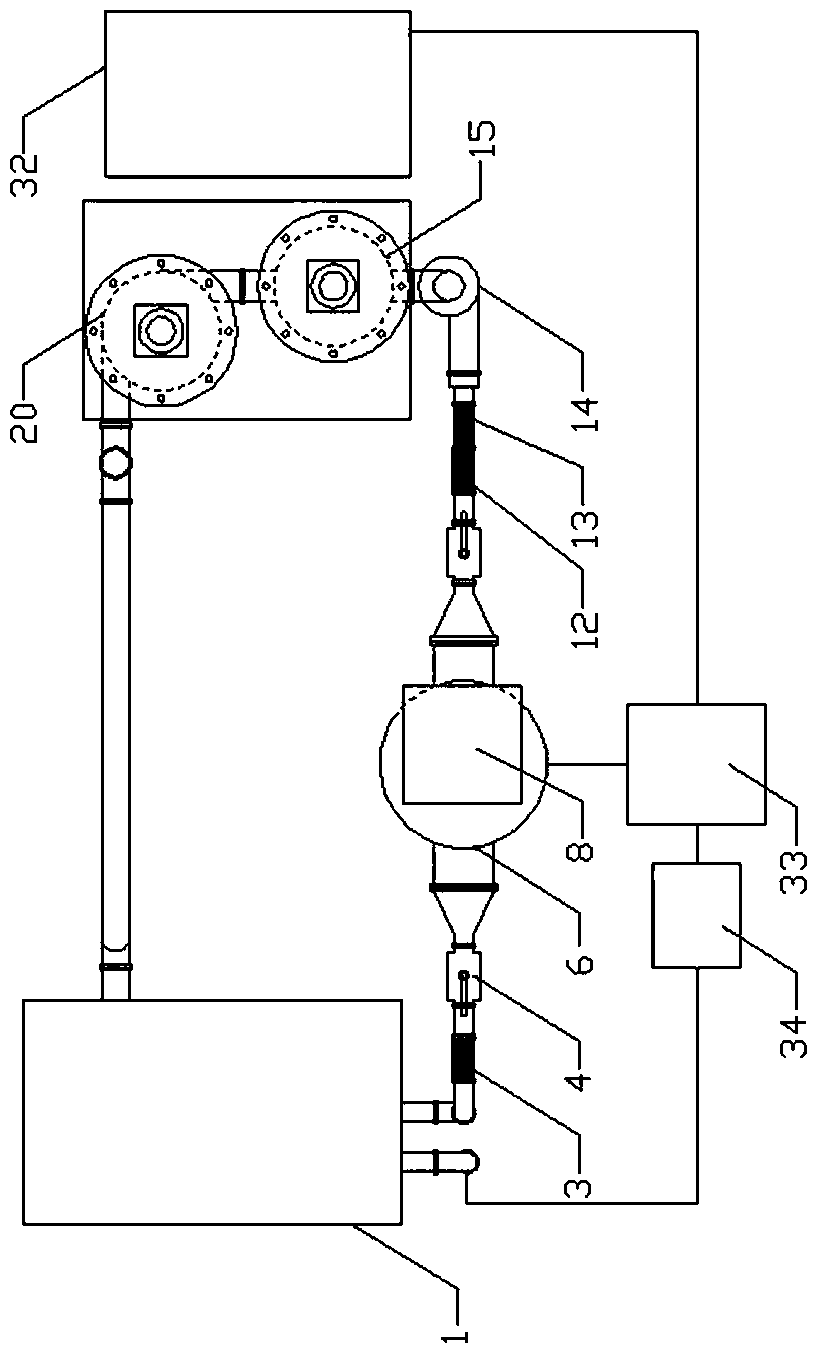

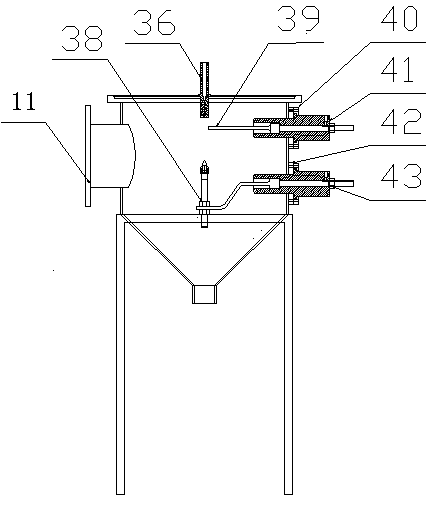

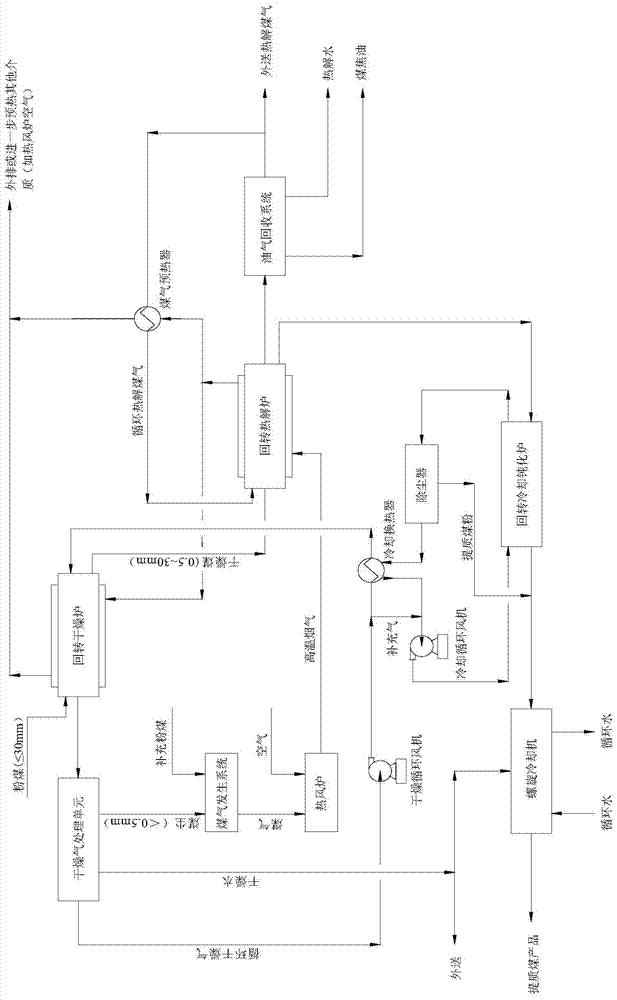

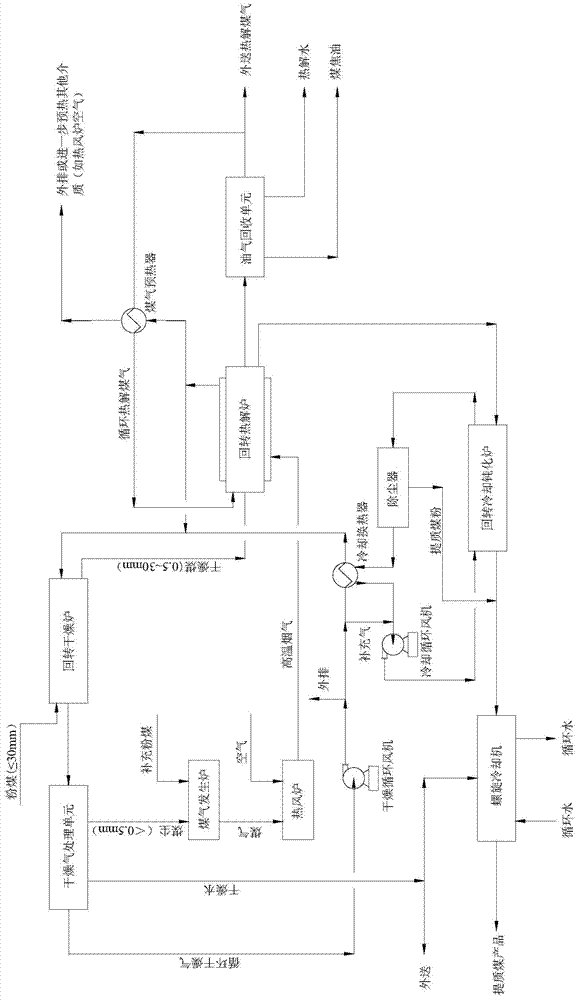

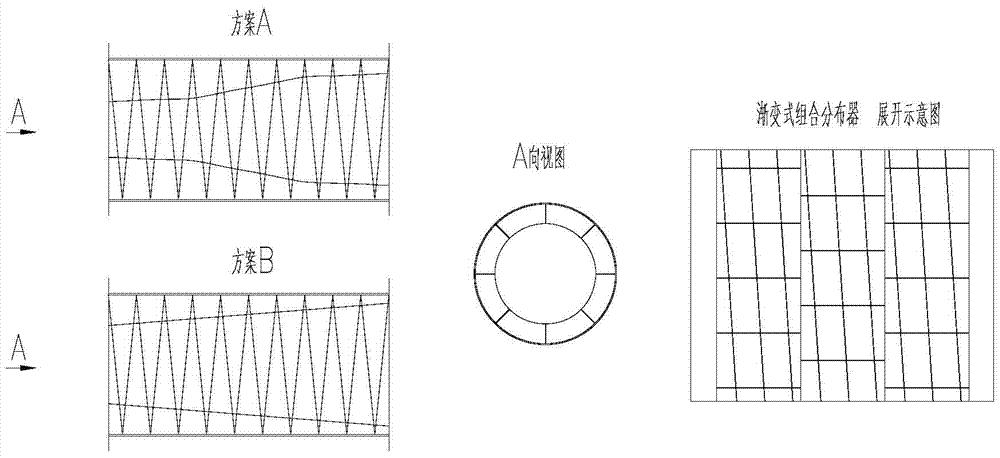

The invention provides a rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation. The rotary furnace low-order powdered coal pyrolysis upgrading method comprises the following steps: heating and drying raw material powdered coal with the granularity less than or equal to 30mm to be 110-280 DEG C in a low-order powdered coal rotary drying system with dust collection, and removing 85% of coal dust with the granularity less than 0.5mm in the powdered coal; feeding the dried coal with the granularity of 0.5-30mm to a downstream rotary pyrolysis system to react at 500-700 DEG C so as to generate upgraded coal and a high-temperature oil gas; feeding the high-temperature upgraded coal to a rotary cooling passivating furnace for primary cooling and medium / low temperature passivation, further cooling by using a spiral cooling machine, spraying water, and discharging out the product; feeding the high-temperature oil gas into an oil gas recycling system, and performing temperature reduction separation, thereby obtaining coal tar, pyrolysis water and pyrolysis coal gas; preheating a part of the pyrolysis coal gas, circulating back to the pyrolysis furnace, and discharging out the rest part of the pyrolysis coal gas.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

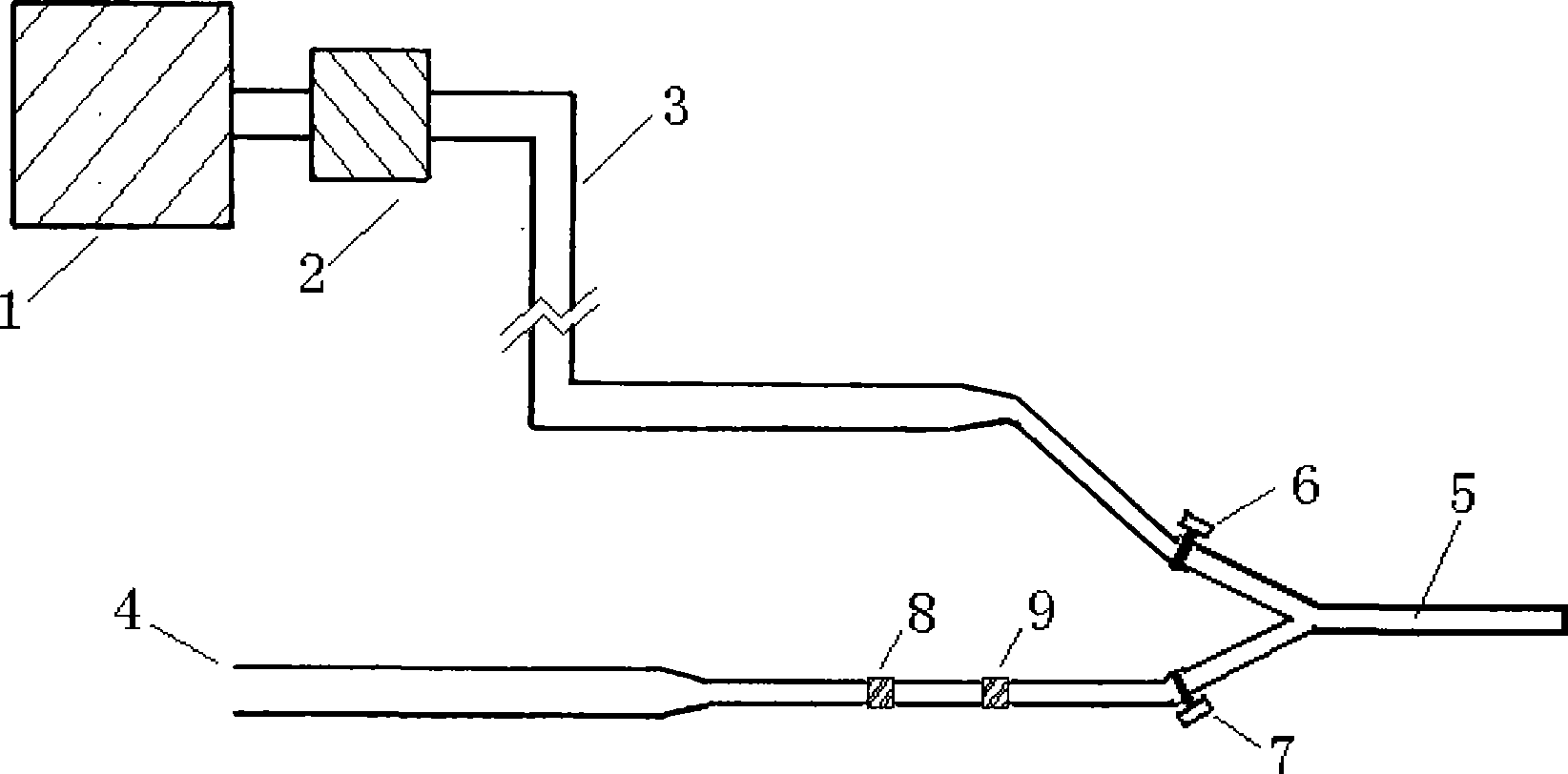

Gas-circulating method for pyrolysis production of anthracite in coal powder rotary furnace

ActiveCN104789244AHigh yieldReduce consumptionIndirect heating destructive distillationSpecial form destructive distillationCoal dustAnthracite

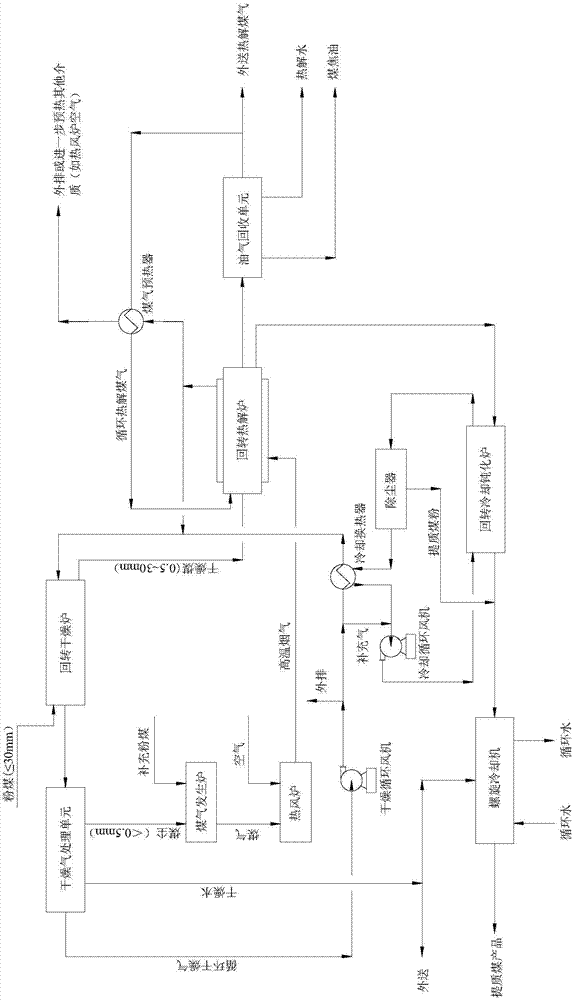

The invention provides a method for pyrolysis production of anthracite in a coal powder rotary furnace. The method relates to a coal powder dust removing rotary drying furnace system, an external-heating rotary furnace pyrolysis system with a coal gas circulation function, a rotary cooling passivation system with a heat recovery function, and an oil gas recovering system, wherein the coal powder dust removing rotary drying furnace system is used for heating coal powder to 110 to 280 DEG C and removing coal dust of which the particle size is smaller than 0.2 mm; drying water is recovered and fed to a downstream spiral cooling machine to be used for anthracite cooling and humidification; the coal dust obtained after separation is fed to a coal gas generating system to generate fuel, namely coal gas; after dust removing, coal is sent to a downstream rotary pyrolysis system for pyrolysis; high-temperature anthracite is generated, and cooled; the cooled anthracite is passivated at a middle-low temperature; the passivated anthracite is cooled in the spiral cooling machine; water is sprayed on the cooled passivated anthracite for humidification; the humidified anthracite is sent out; high-temperature oil gas produced in the process enters the oil gas recovering system to obtain coal tar, pyrolyzed water and coal gas. Part of the produced pyrolyzed coal gas returns to the pyrolysis furnace after preheating in a circulating manner, while the other part of the produced pyrolyzed coal gas is sent out.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

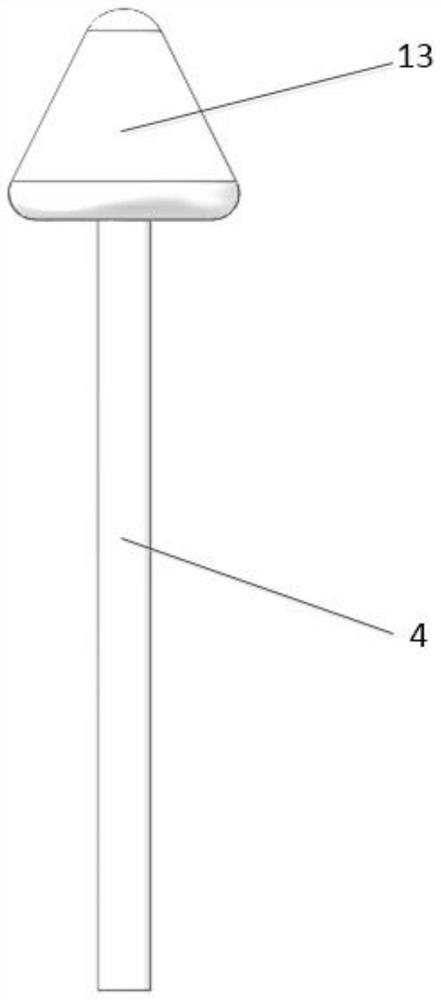

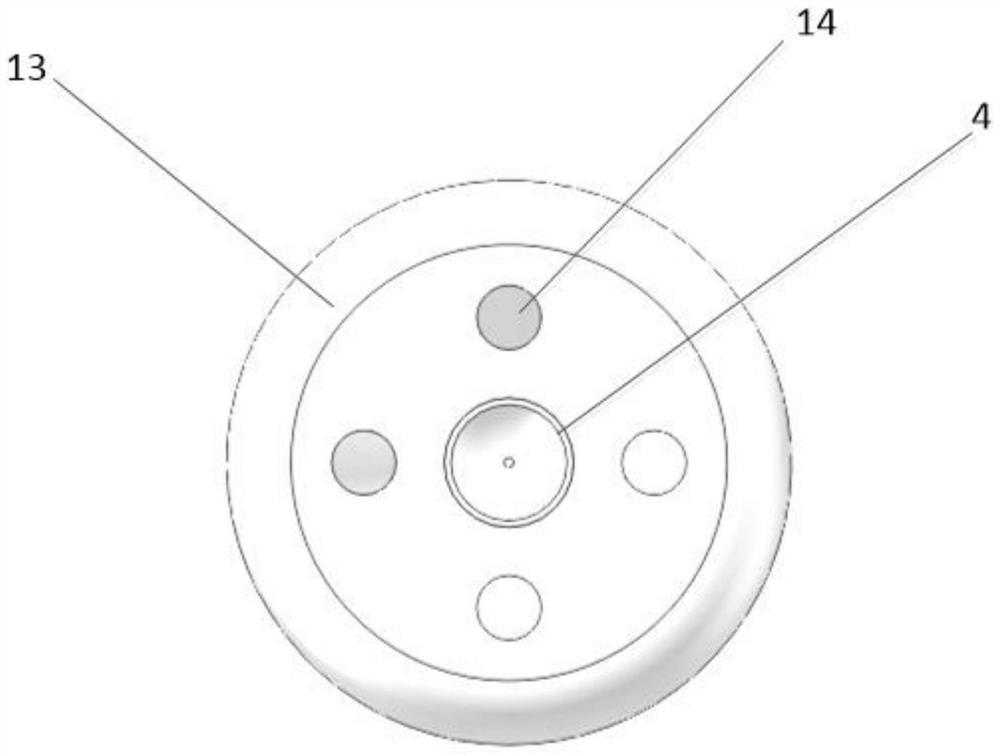

Equipment for preparing nano powder by electrical explosion method

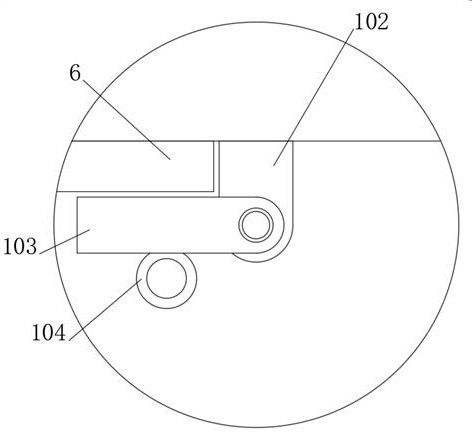

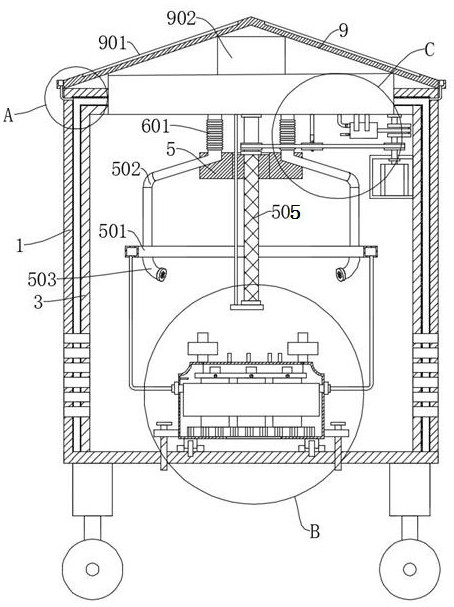

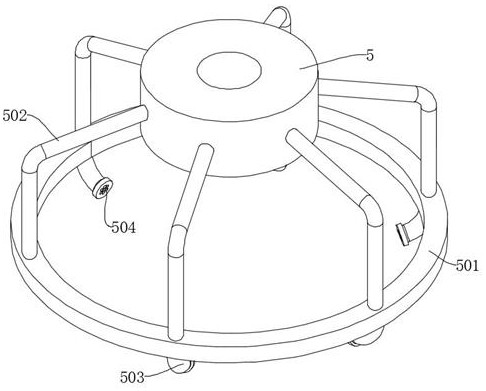

ActiveCN106807310AChange rotation speedAchieve straightening and conveyingEnergy based chemical/physical/physico-chemical processesMicroballoon preparationElectricityNanoparticle

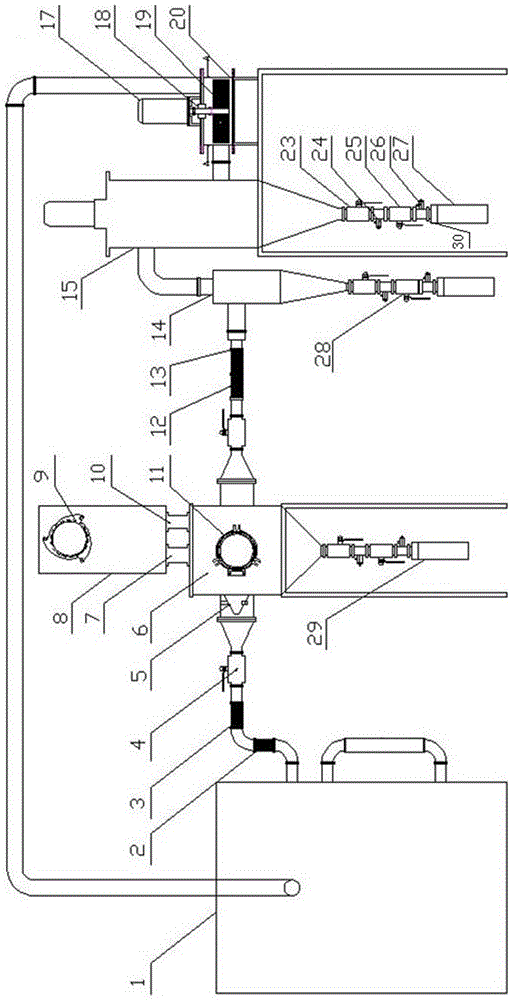

The invention discloses equipment for preparing nano powder by an electrical explosion method, and belongs to the field of nanomaterial preparation. The equipment aims at solving the problem that the conventional nano powder production equipment has a strict requirement for an insulating structure and an insulating material of a high-voltage part. The equipment comprises a nano powder reaction mechanism, an electrical explosion generation mechanism, a wire feeding mechanism matched with the nano powder reaction mechanism, an air cooler, a first connecting tube, a first insulating tube, a second connecting tube, a second insulating tube and a third connecting tube. According to the equipment, instant high voltage is generated by electrodes, so that materials in an explosion reaction cavity react to generate corresponding nano particles. Due to an improvement of a structure, the working voltage of the equipment is equal to or lower than 25KV, and a high-voltage part has a very low requirement for a high-voltage structure and a withstand voltage material. In addition, raw materials of the equipment are filamentary materials and non-insulators, so that the equipment has the characteristics of wide raw material source and high adaptability, and has good universality for various filamentary non-insulator materials.

Owner:四川弘博新材科技股份有限公司

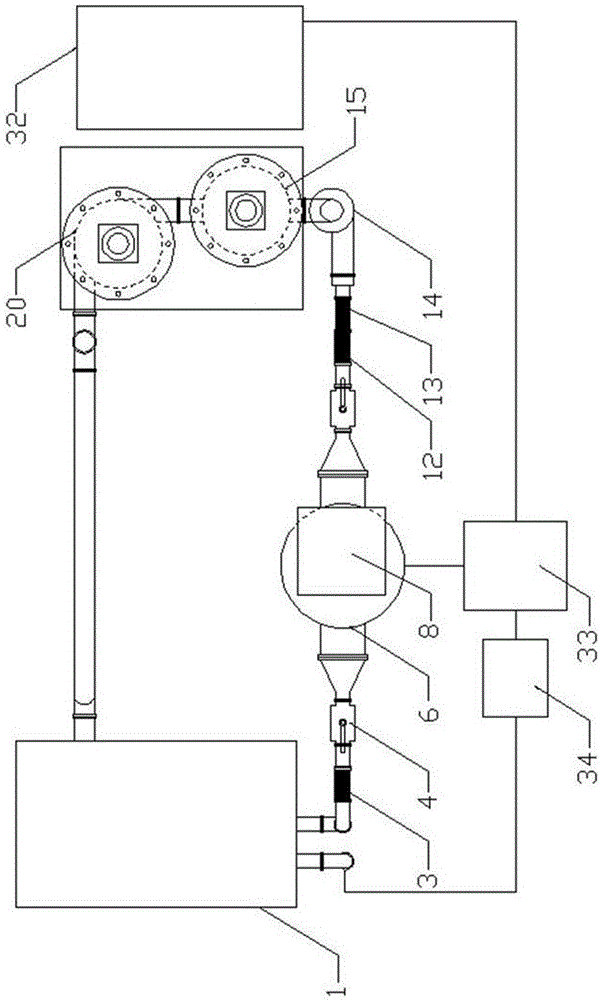

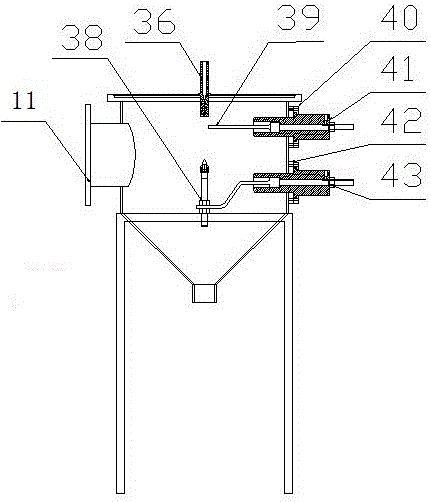

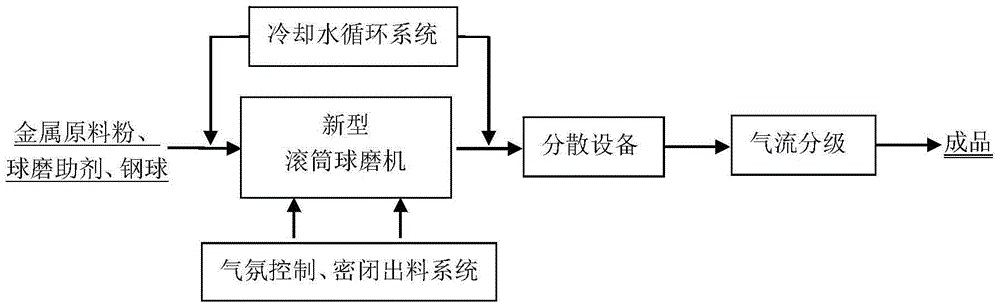

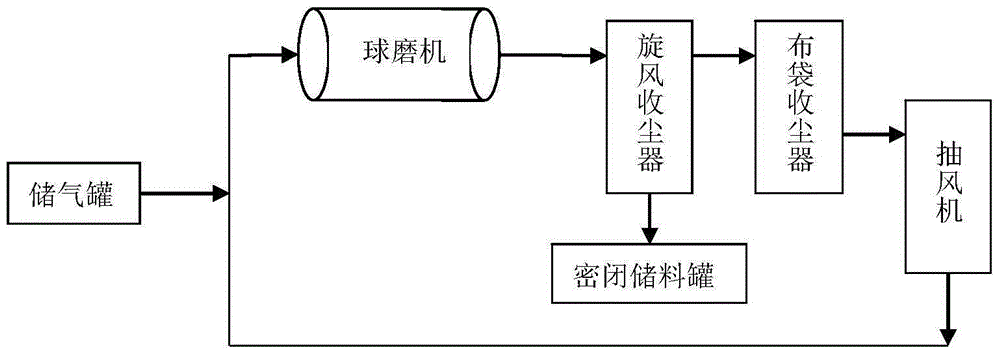

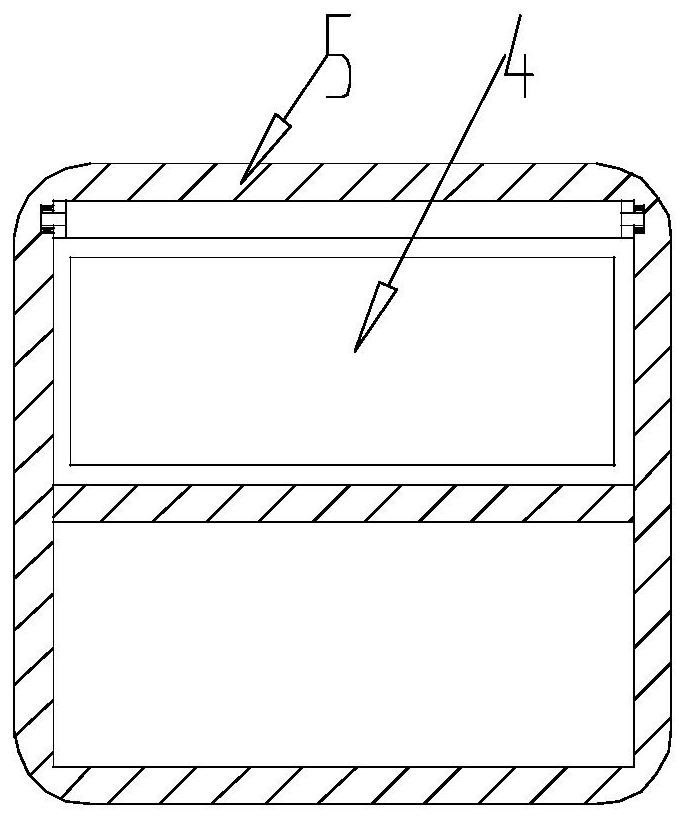

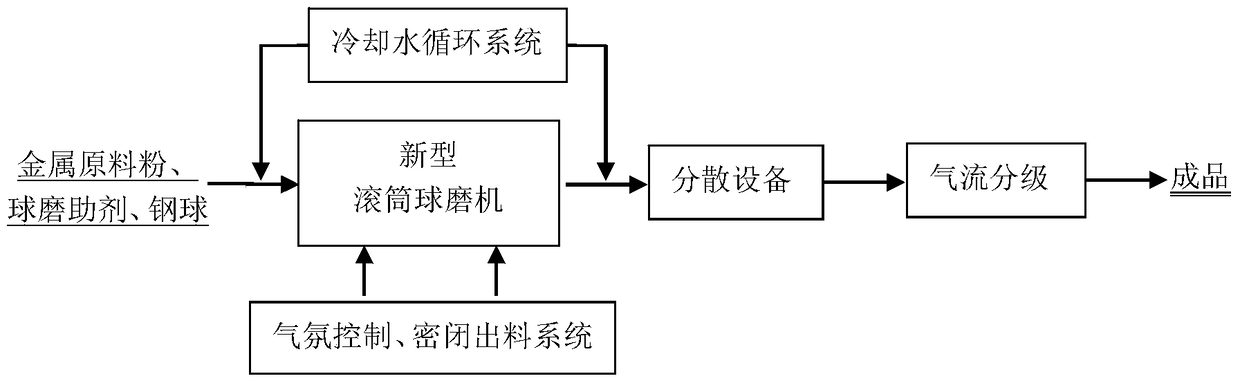

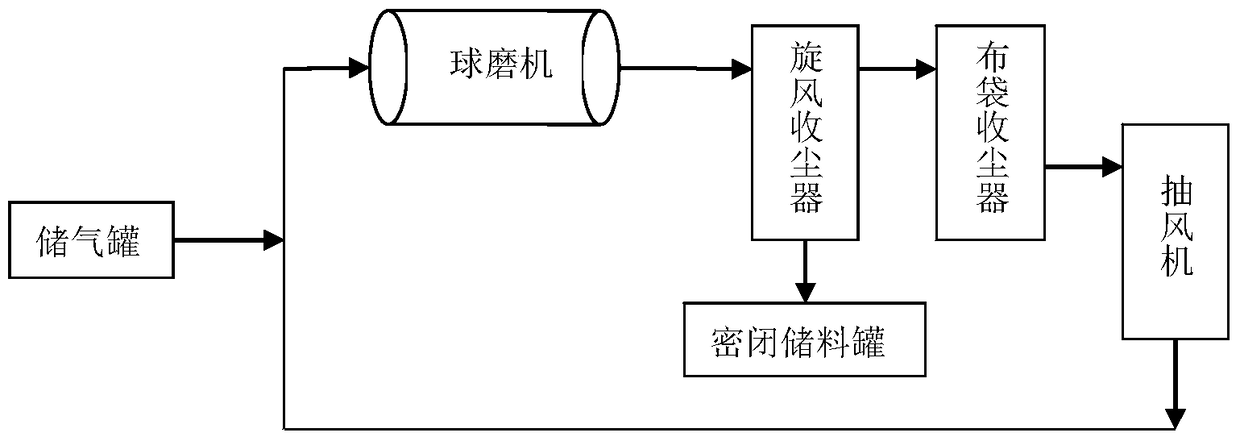

Method and device for preparing flaky metal powder by means of dry ball mill

The invention provides a method for preparing flaky metal powder by means of a dry ball mill. The method comprises the steps that metal raw material powder and ball milling additives are evenly mixed, a mixture and a steel ball are put in a closed novel roller ball mill for ball milling in proportion, the ball milling temperature is controlled through a cooling water circulation system in the ball milling process, and the ball milling atmosphere in a roller is adjusted through a ball milling atmosphere control system; a closed discharging system is adopted for discharging, inert gas of certain pressure is input, an exhaust fan and the ball mill are started, and ground metal powder in the ball mill is blown and sucked out in a blowing and sucking manner; and the metal powder is put in dispersion equipment again to be dispersed, and is graded by airflow grading equipment to obtain finished products. The invention relates to a device for achieving the method. According to the method, the whole process is high in automation degree, no steel ball transfer exists, and the labor intensity and workloads of workers are greatly reduced. In addition, the sealing performance and the cooling effect are good, no dust pollution exists, the phenomena of powder oxidation and spontaneous combustion in the powder discharging process are avoided, the yield is large, and production efficiency is greatly improved.

Owner:SHENZHEN NONFEMET TECH

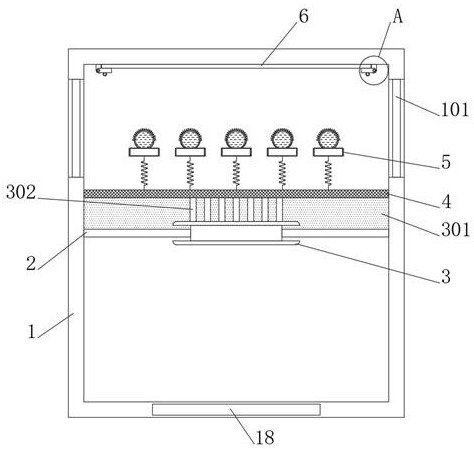

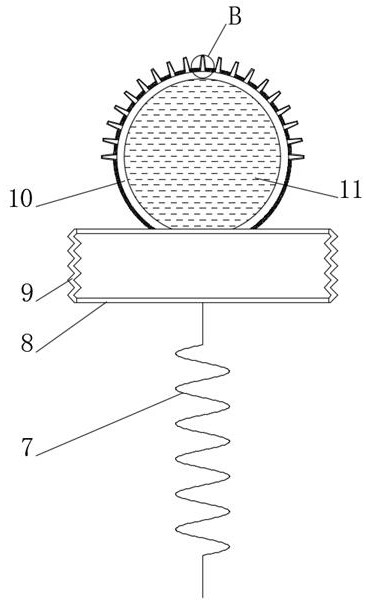

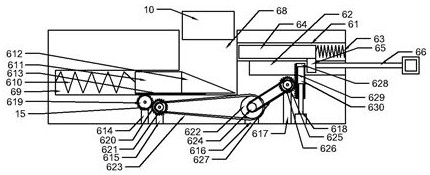

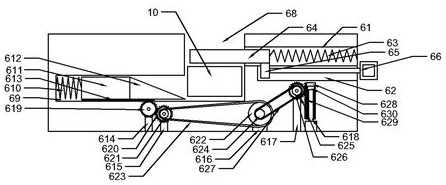

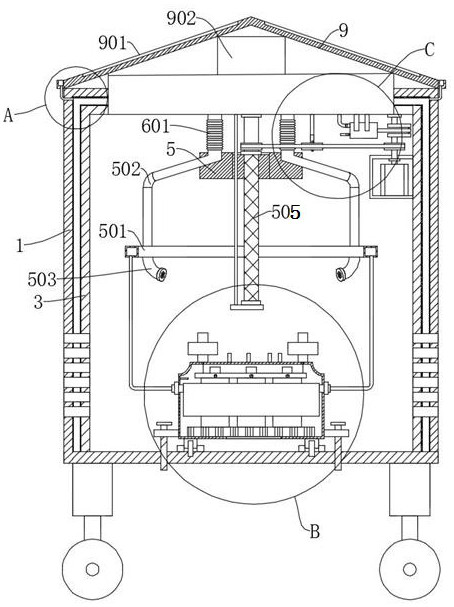

Deforming contact type fabric fluff removal device

ActiveCN111648111AImprove adhesionAccelerate sinkingMechanical cleaningPressure cleaningEngineeringHot melt

The invention discloses a deforming contact type fabric fluff removal device, and belongs to the technical field of clothing processing. A semiconductor refrigeration sheet is heated to 60 DEG C and the heat is transferred to a fluff collecting device. With the expansion of a lifting air bag, the lifting air bag can be promoted to move up until the fluff collecting device comes to contact with fabric. Meanwhile, by intermittently starting and turning off an electromagnet, the fluff collecting device can repeatedly move up and down between a bearing filter screen and the fabric and collect fluff adhering to the surface of the fabric with the help of collecting bore spines and hot melt adhesive layers at the outer ends of fluff collecting balls. When the fluff collecting balls come into contact with the fabric, the fluff collecting balls can squeeze the fabric until the fluff collecting balls become flat balls, and the collection efficiency of the fluff adhering to the surface of the fabric is increased. Meanwhile, traction particles are released, so that the fluff adhering with the traction particles can be adsorbed downward and collected. Moreover, the antistatic property of the fabric can be improved through an antistatic powder layer, and the possibility of the fluff adhering to the fabric again can be reduced.

Owner:SHANDONG TAROKO WEAVING & DYEING IND

Spray coating material for preventing air leakage in roadway, use method thereof and special spray gun

The invention discloses a coating material used for preventing the air leakage of a laneway, an application method and a special spray gun thereof. The components of the coating material are clay, cement, sodium silicate, glass fiber and water which are mixed, stirred and made into clay cement slurry according to certain proportion and processes. The clay cement slurry is transported to an underground spraying area by a slurry pump through a grouting pipe, and sprayed to a coal roadway wall by the special spray gun to prevent the air leakage of the laneway. The clay cement slurry has strong suspension property, short initial concreting time, certain strength after solidification, rinse-resistance, not easy craze, excellent air partition performance, strong flame-retardant property, ideal effect of preventing the air leakage of the laneway, quick shotcreting process operations, safety and simplicity, is applicable to the spraying to the coal roadway walls of mines with serious hazards, and prevents the air leakage of the laneway so as to reduce the possibility of the occurrence of spontaneous combustion.

Owner:冀中能源股份有限公司葛泉矿

Preparation method for composite inhibitor used for preventing and handling serf-combustion of coal

InactiveCN107033924AGood dispersionEffective prevention and control of spontaneous combustionDust removalFire preventionIon exchangeOxygen

The invention specifically relates to a preparation method for a composite inhibitor used for preventing and handling serf-combustion of coal, belonging the technical field of prevention of serf-combustion of coal. The preparation method comprises the following steps: with sodium-based montmorillonite as a raw material, carrying out ultrasonic dispersion and then subjecting the dispersed sodium-based montmorillonite to ion exchange with ferric trichloride; then with cetyl trimethyl ammonium bromide as an intercalator, preparing high-dispersibility modified iron-based montmorillonite; subjecting reduced iron powder, graphite and copper powder to ball milling and alloyage and carrying out physical combination under the action of pressure to form a short-circuit corrosion microbattery together so as to improve an oxygen uptake rate; then loading modified iron-based montmorillonite with magnesium chloride; and then carrying out compounding with carboxymethyl cellulose, ethyl acetate, gelatin and the like so as to obtain the composite inhibitor used for preventing and handling serf-combustion of coal. The composite inhibitor used for preventing and handling serf-combustion of coal can deeply enter the pores of coal, consumes oxygen in a surrounding environment, reduces the temperature of coal due to its water absorption performance, decreases contact between coal and oxygen and lowers the possibility of serf-combustion of coal.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

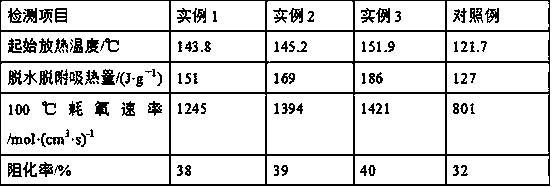

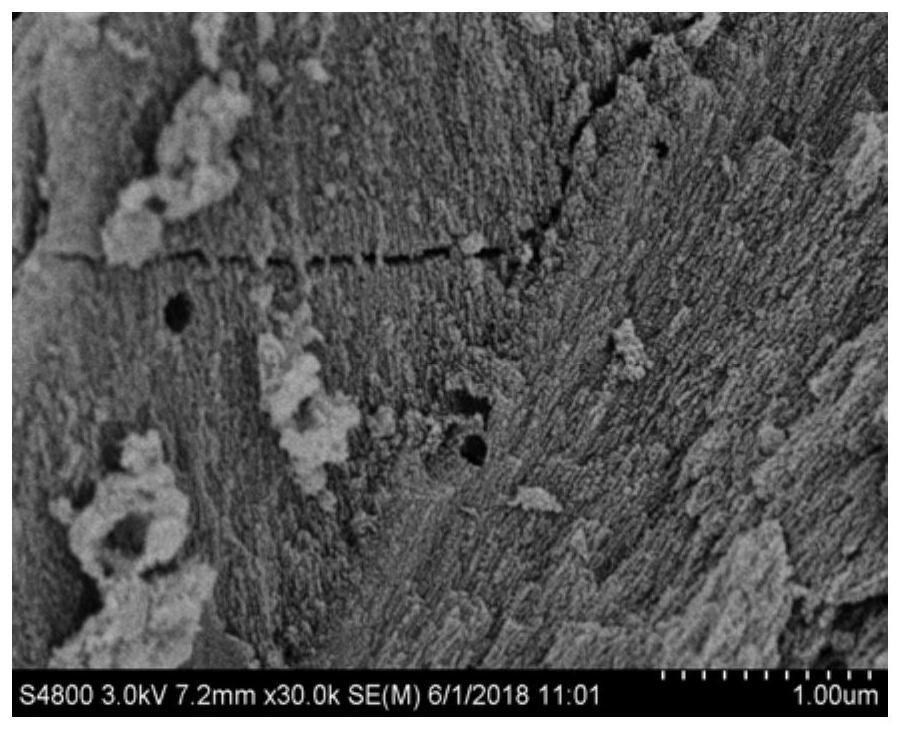

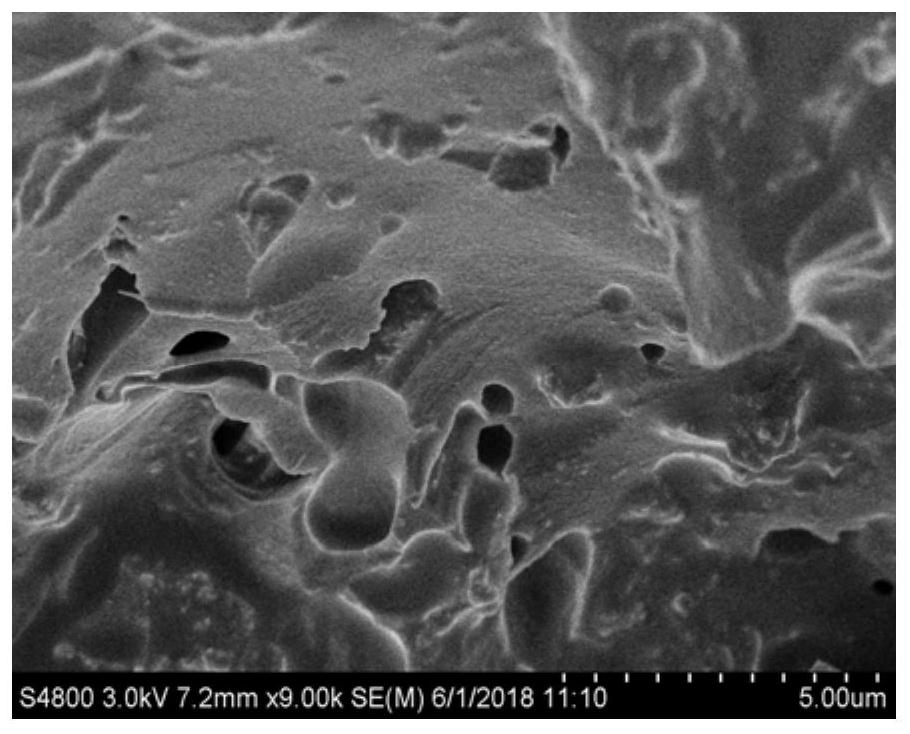

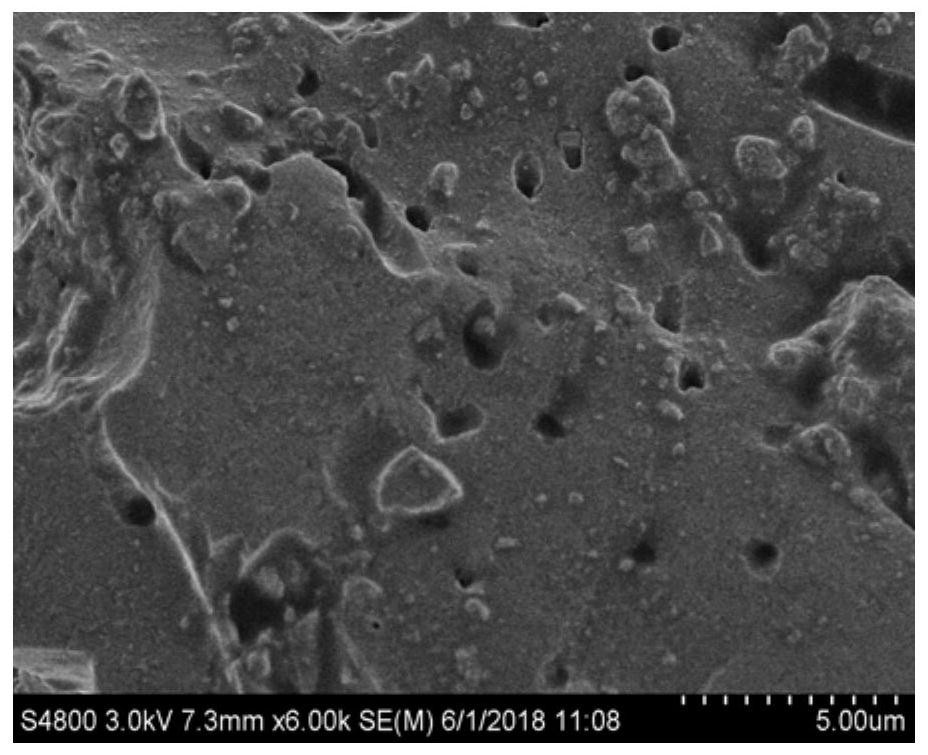

Application of ionic liquid in preparation of modified active carbon, modified active carbon and preparation method of modified active carbon

ActiveCN110064365AChemically stableIncreased distribution of viasOther chemical processesSpontaneous combustionActivated carbon

The invention relates to the technical field of adsorption materials, in particular to application of ionic liquid in preparation of modified active carbon, the modified active carbon and a preparation method of the modified active carbon. The preparation method comprises the following steps of mixing the ionic liquid with active carbon, carrying out constant-temperature treatment at 100-120 DEG Cfor 24-36 hours, and then carrying out separation treatment to obtain the modified active carbon. According to the provided modified active carbon, the saturated adsorption capacity of organic wastegas is increased by about 120%, the spontaneous combustion point is increased by about 30 DEG C, the adsorption efficiency of the modified active carbon is improved, the spontaneous combustion point becomes higher, and the possibility of spontaneous combustion is reduced.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Materialized synergistic coal inhibitor and preparation method thereof

InactiveCN108868870AHigh densityImprove flame retardant performanceDust removalFire preventionAntioxidantRare earth

The invention relates to a materialized synergistic coal inhibitor and a preparation method thereof and belongs to the technical field of mines. A sodium polyacrylate salt is used in a water absorbingswelling effect of super absorbent resin, and the physical inhibitor is obtained under the combined action of aqueous resin colloid and rare earth hydrotalcite; due to the high water content and thehigh water retaining performance, the physical inhibitor has the functions of heat absorption and temperature lowering and the effects of blocking oxygen and preventing heat transfer, and suppressionof a coal oxygen reaction is facilitated. At the same time, the affinity of the rare earth hydrotalcite and oxygen is higher than that of magnesium and oxygen, in the process of oxidation and temperature raising, the rare earth hydrotalcite reacts with oxygen and magnesium oxide to generate rare earth oxides and reduce magnesium, and a small amount of aluminum also reacts with oxygen to generate aluminum oxide, so that the density of a barrier layer is increased, the flame retardancy of hydrotalcite-like compounds to polymers is greatly improved, and reduced magnesium, graphite powder and copper powder together constitute a short-circuited corrosion micro-battery for increasing the oxygen absorption rate and synergizing with an antioxidant to capture active radical groups and block a chainoxidation reaction.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

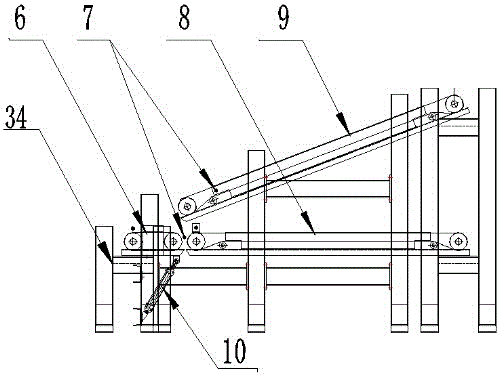

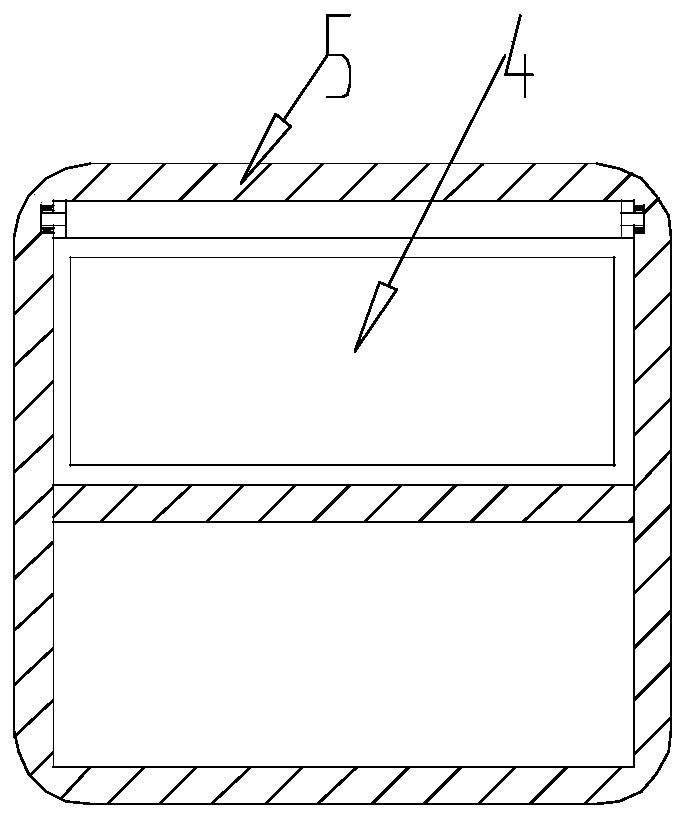

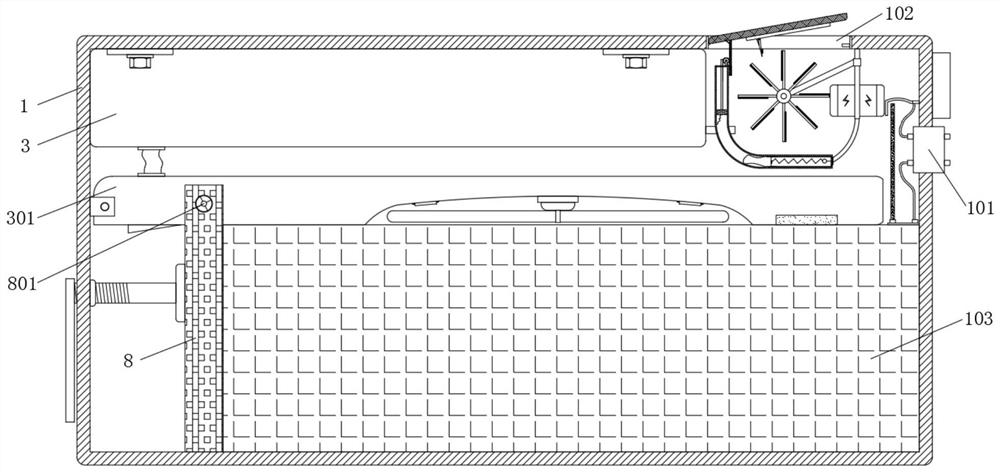

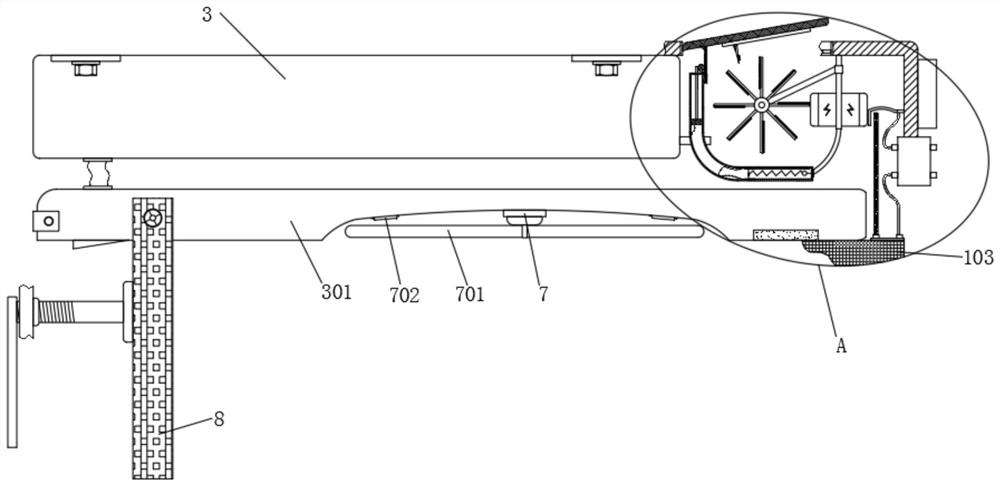

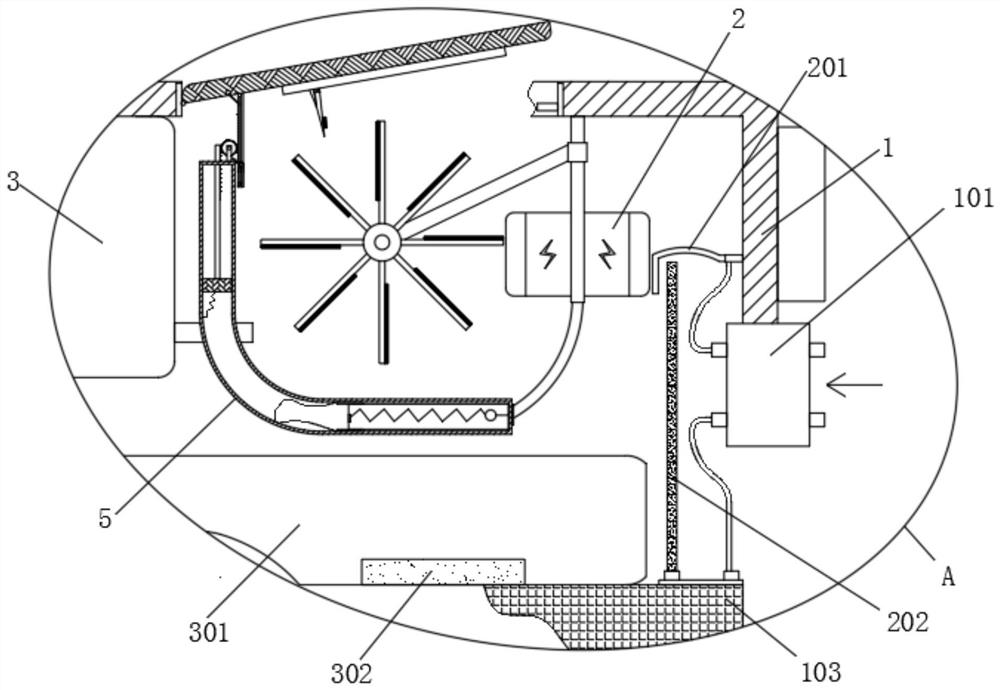

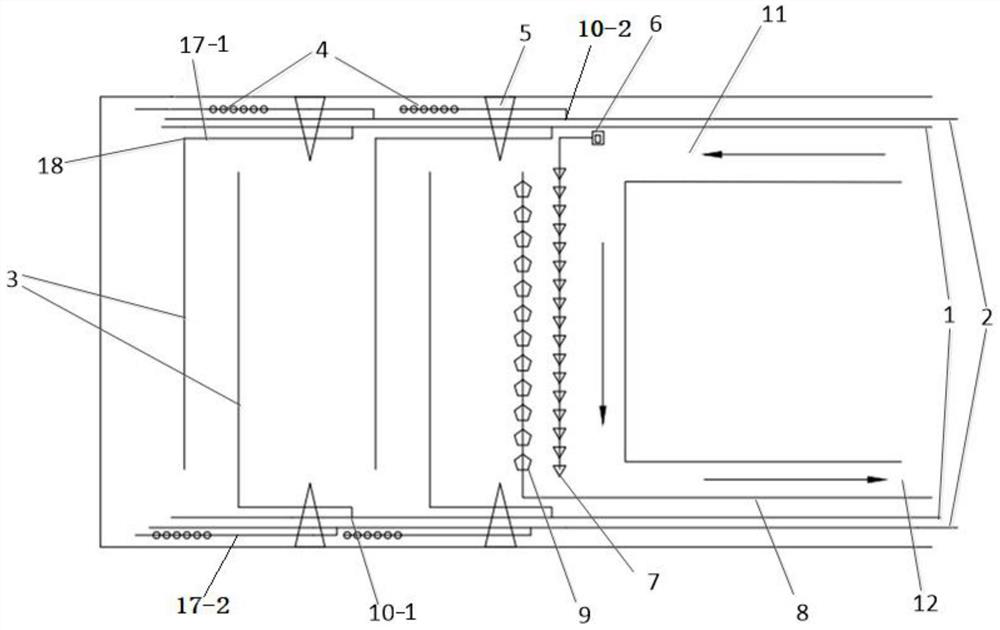

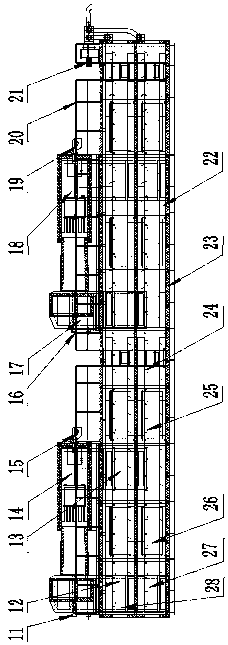

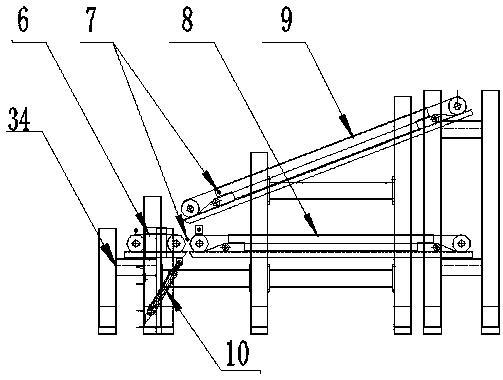

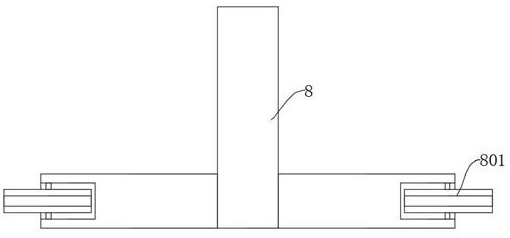

Hot air vulcanization equipment

ActiveCN106003497AReduce the possibility of spontaneous combustionImprove securityHot blastExhaust fumes

The invention discloses hot air vulcanization equipment. The hot air vulcanization equipment comprises a vulcanization tank, and a vulcanization conveying chain is arranged in the vulcanization tank. A vulcanization line feeding inlet combustor and a vulcanization line discharging outlet combustor are arranged on the top of the vulcanization tank. A vulcanization line feeding inlet combustion engine is arranged on one side of the vulcanization line feeding inlet combustor, and a vulcanization line feeding inlet circulating fan is arranged on the other side of the vulcanization line feeding inlet combustor. A vulcanization line feeding inlet air supply channel is arranged below the vulcanization line feeding inlet circulating fan. A vulcanization line air return channel is arranged in the vulcanization tank. A vulcanization line discharging outlet combustion engine is arranged on one side of the vulcanization line discharging outlet combustor, and a vulcanization line discharging outlet circulating fan is arranged on the other side of the vulcanization line discharging outlet combustor. A vulcanization line discharging outlet air supply channel is arranged below the vulcanization line discharging outlet circulating fan. A waste air exhaust fan is arranged in a discharging outlet of the vulcanization tank. The hot air vulcanization equipment has the beneficial effects that the production safety coefficient is high, cost is low, the vulcanization time is short, the vulcanization efficiency is high, and the vulcanization effect is good.

Owner:GUIZHOU DAZIRAN TECH

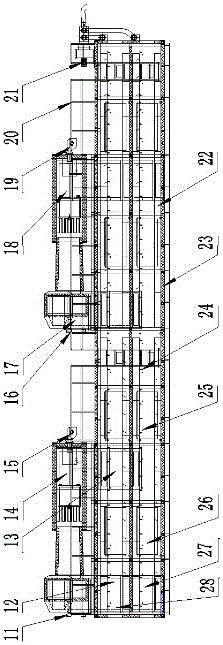

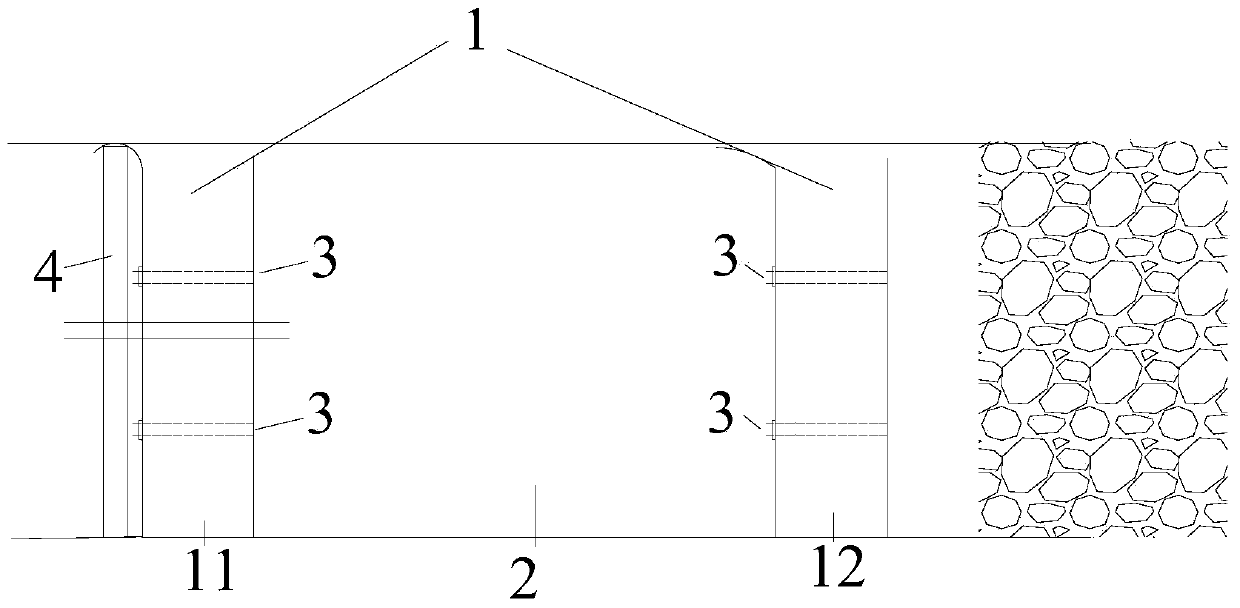

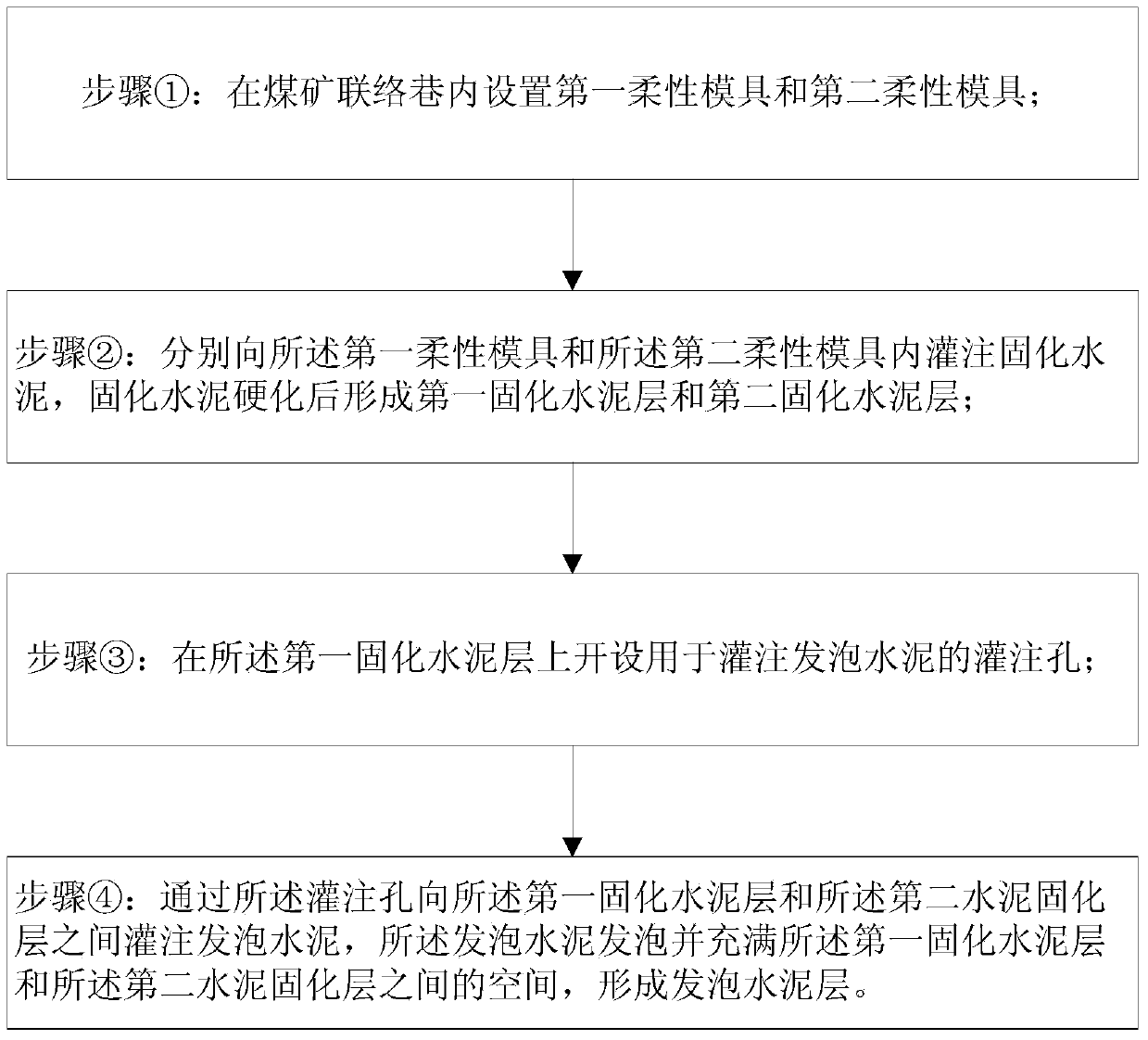

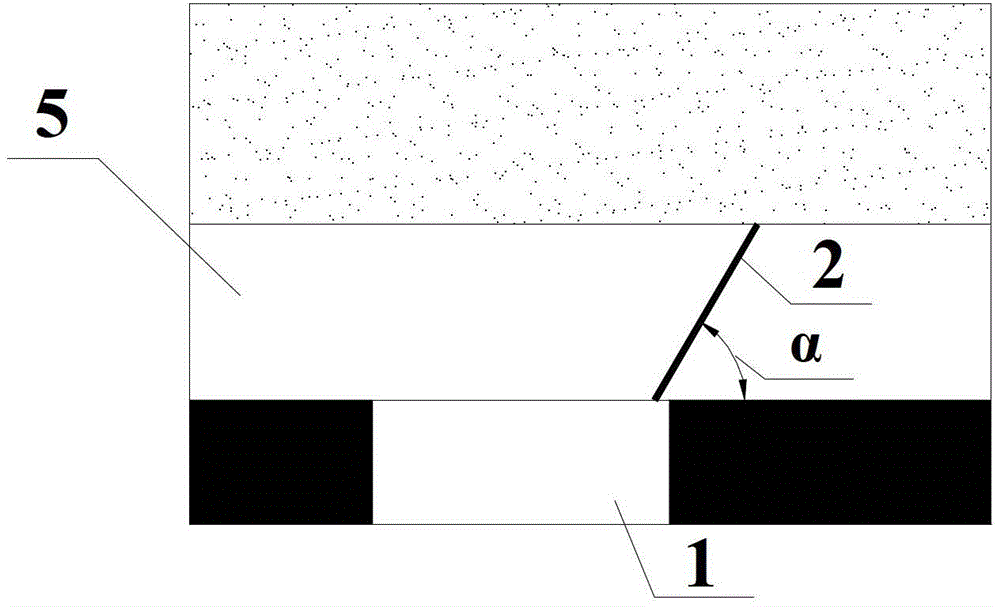

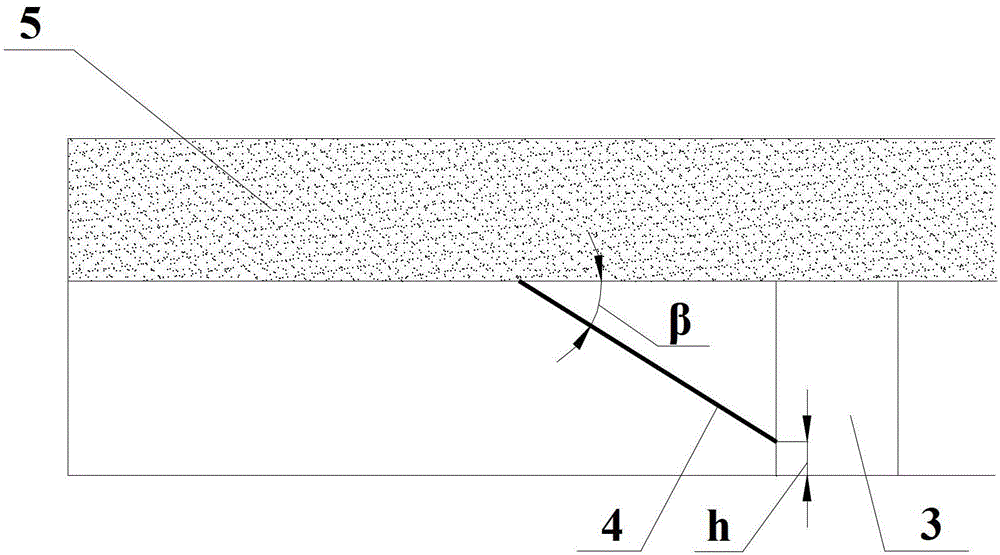

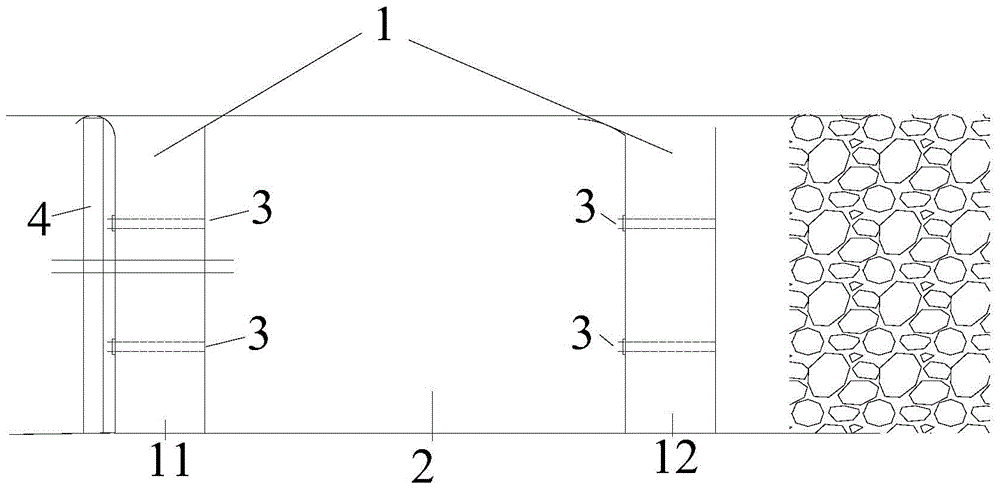

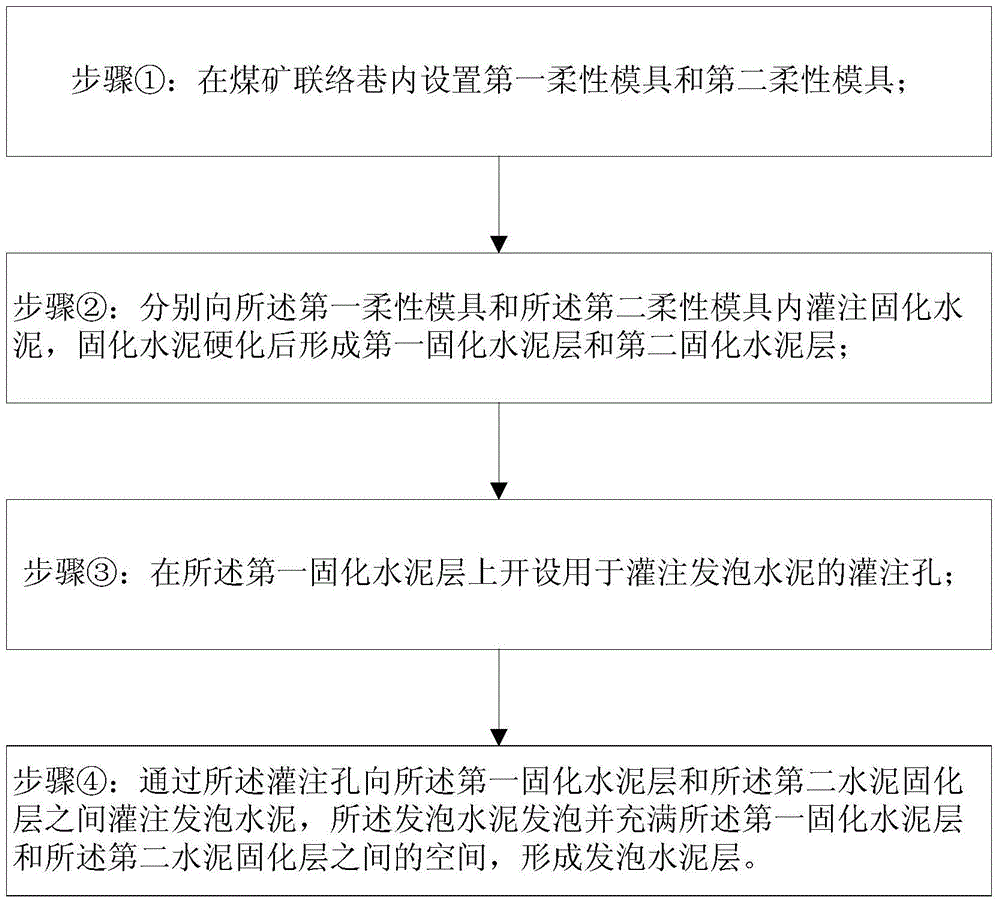

Coal mine connection roadway and sealing method thereof

ActiveCN104179527AImprove poor plasticityImprove sealingMining devicesSpontaneous combustionPolymer science

The invention discloses a coal mine connection roadway and a sealing method thereof. The coal mine connection roadway comprises solidified cement layers and a foamed cement layer, wherein the solidified cement layers and the foamed cement layer are vertically arranged in the coal mine connection roadway; the solidified cement layers comprise a first solidified cement layer and a second solidified cement layer; the foamed cement layer is arranged between the first solidified cement layer and the second solidified cement layer; filling holes which are used for filling foamed cement are further formed in the first solidified cement layer. The foamed cement layer is filled by foamed cement materials which are less in heat release after being physically expanded and relatively low in cost, so that the sealing cost of the coal mine connection roadway can be effectively reduced, the sealing efficiency is improved, and the spontaneous combustion possibility of float coal at the top of the connection roadway is reduced; by virtue of the solidified cement layers arranged on two sides of the foamed cement layer, the problem that the foamed cement is low in plasticity is solved, so that the sealing property of the foamed cement layer is improved favorably.

Owner:CHINA SHENHUA ENERGY CO LTD +2

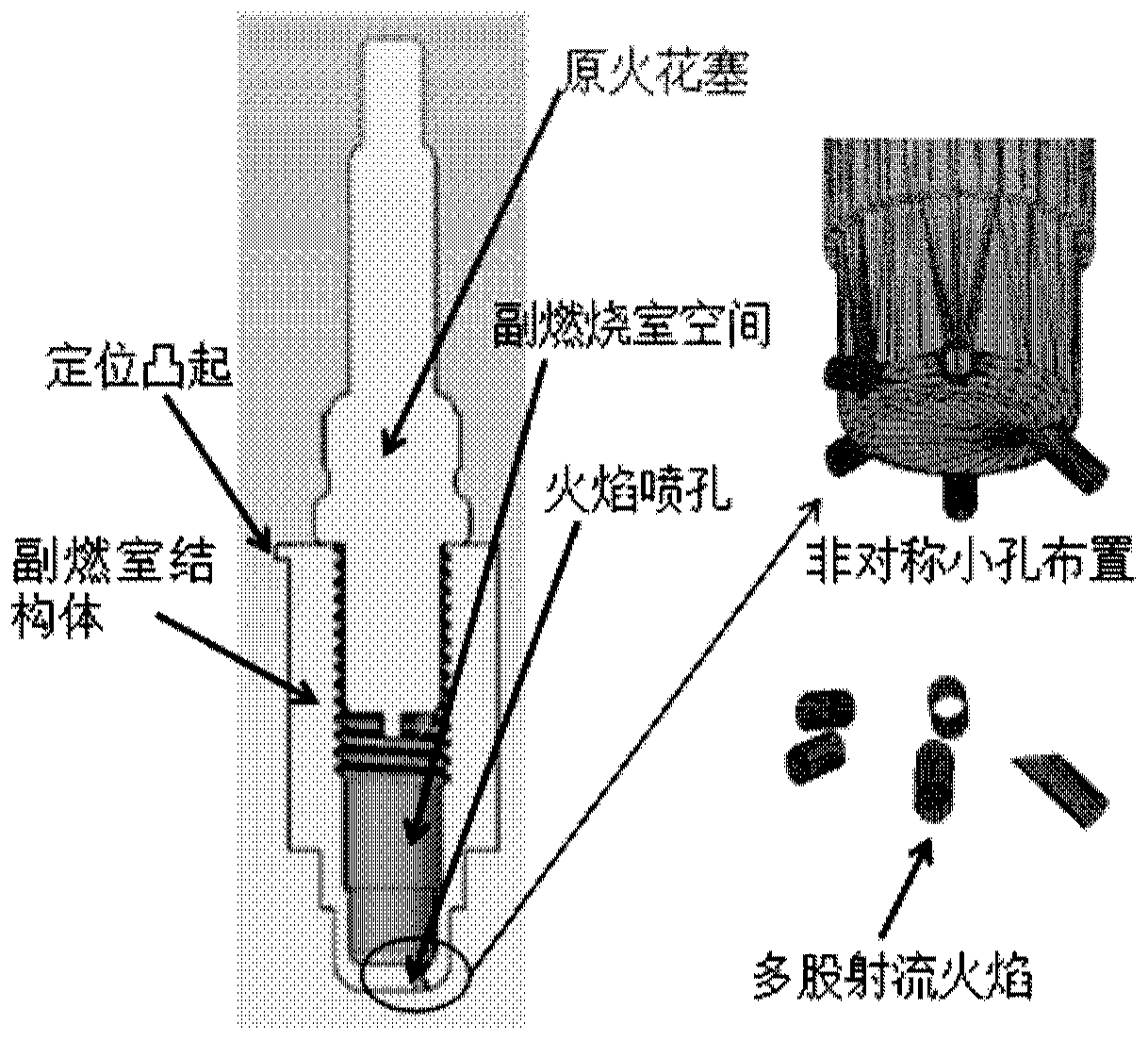

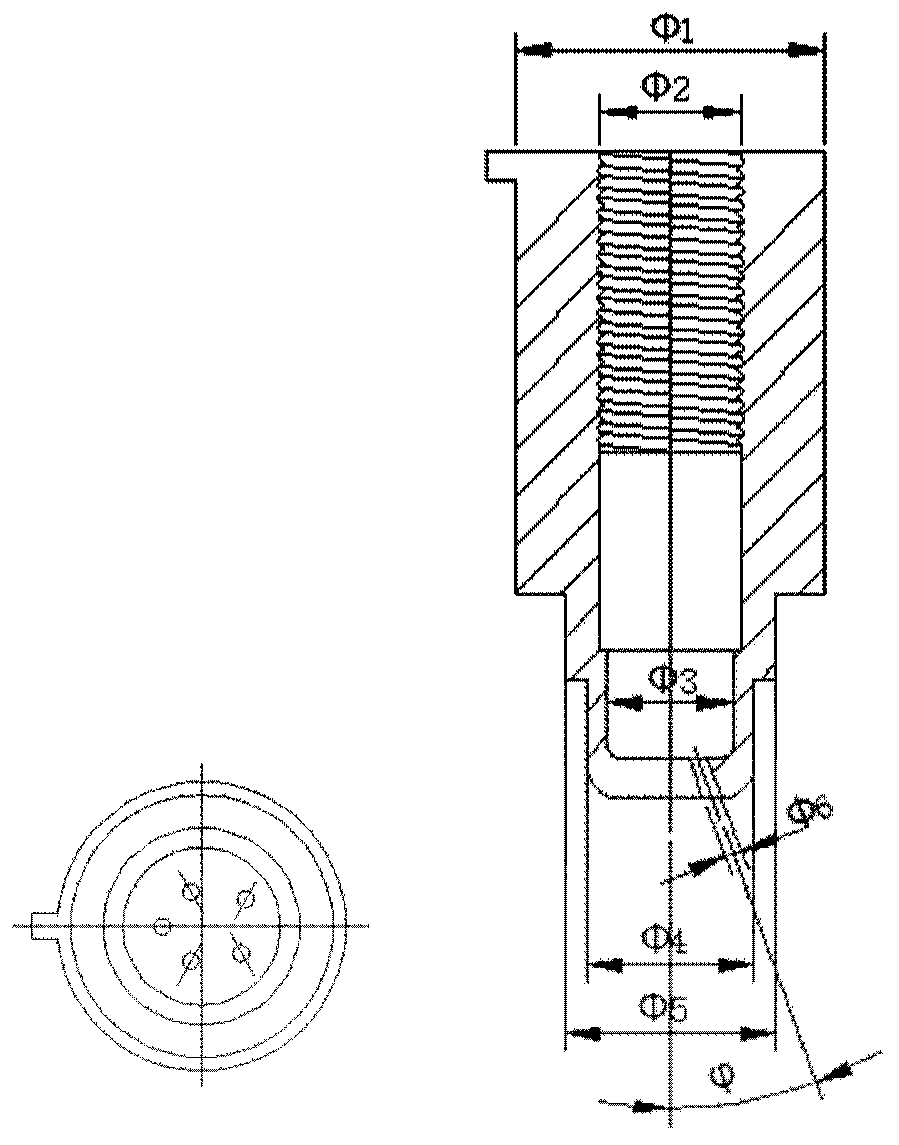

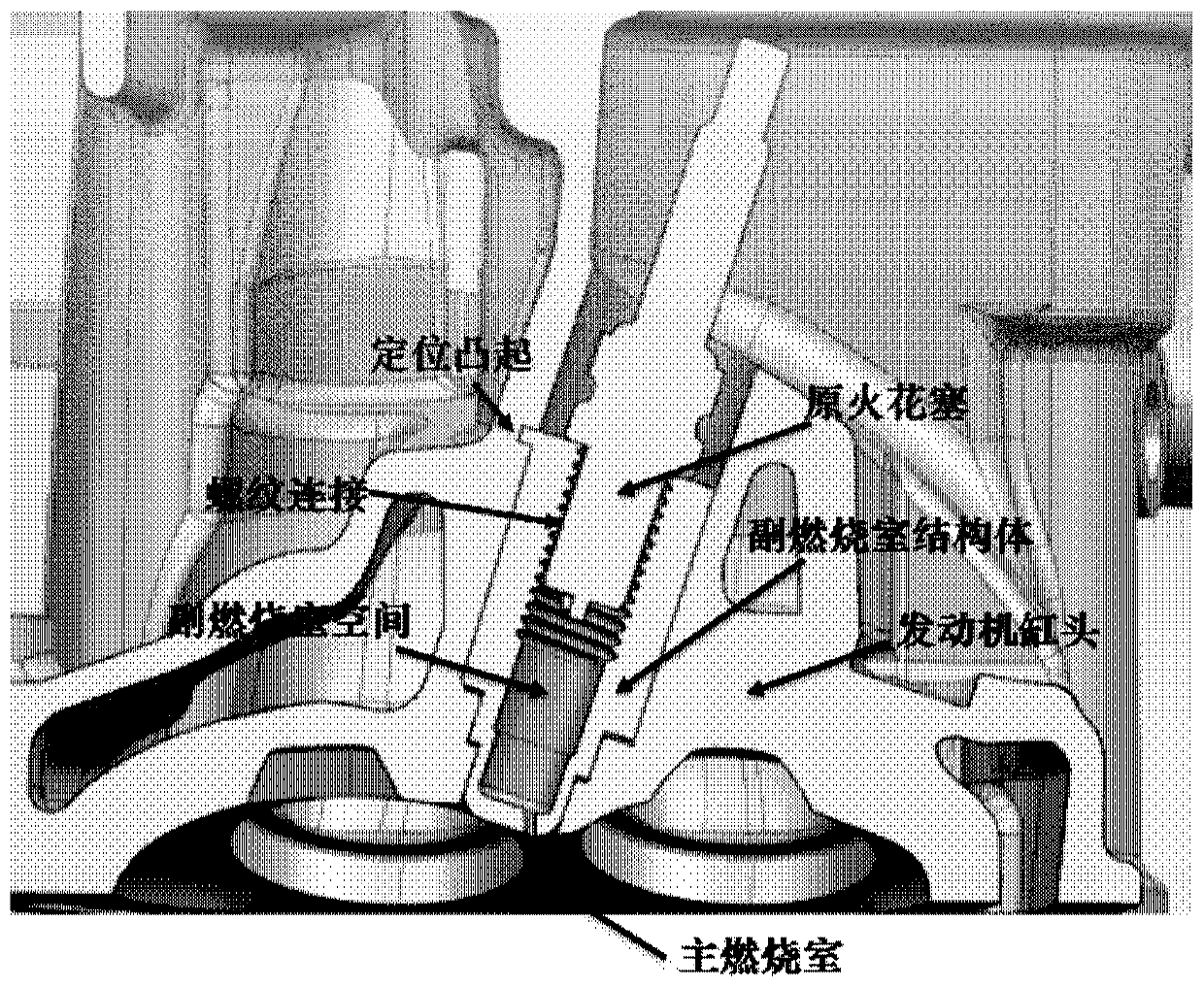

Engine rapid combustion device suitable for low-evaporation characteristic fuel

PendingCN111485992ABurn fasterFast ignitionInternal combustion piston enginesCombustion chamberMixed gas

The invention relates to an engine combustion device. The engine combustion device comprises a main combustion chamber, a spark plug, an auxiliary combustion chamber and flame spray holes, wherein initial flames are generated in the auxiliary combustion chamber through discharging of the spark plug, then the flames are generated in the auxiliary combustion chamber and develop rapidly, then multiple jet flames are generated through the plurality of spray holes used for connecting the auxiliary combustion chamber with the main combustion chamber, the multiple jet flames are jetted into the maincombustion chamber at the same time and are equivalent to a high-energy multi-core ignition source of the main combustion chamber, and mixed gas in the main combustion chamber is ignited by multiple large-area flames at the same time. According to the engine combustion device, the combustion speed of the mixed gas is increased, the ignition stability and reliability are improved, and the knockingphenomenon can be effectively restrained.

Owner:天津内燃机研究所(天津摩托车技术中心)

New energy automobile wire harness assembling frame

InactiveCN112909708AClear in timeEasy to disassemble and replaceContact member assembly/disassemblySpontaneous combustionNew energy

The invention is suitable for the field of new energy automobiles, and provides a new energy automobile wire harness assembling frame which comprises a bottom plate, a supporting seat is installed at the bottom of the bottom plate, a rack is installed above the bottom plate, a heat dissipation device is installed at the top of the rack, a supporting plate is installed in the middle of the rack, a fixing device is installed in the supporting plate, an assembling frame is arranged above the supporting plate, a wiring port is formed in the assembling frame, a connecting rod is installed at the bottom of the assembling frame, a fixing block is installed at the bottom of the connecting rod, and the fixing block matches a fixing device. According to the device, the assembling frame is split, the fixing device is used to fix the assembling frame inside the rack, disassembly, replacement or carrying is easy, and meanwhile, a heat dissipation device is additionally arranged, so that the temperature in the rack can be removed in time, the temperature is reduced in time, and the possibility of spontaneous combustion is reduced.

Owner:宁波米锐汽车配件技术有限公司

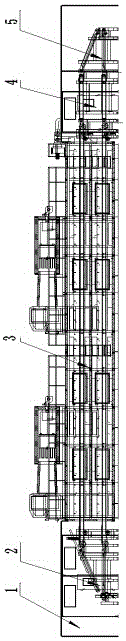

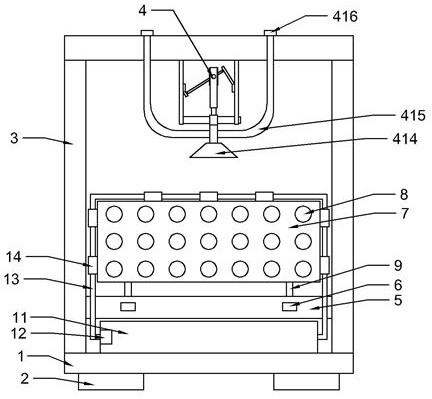

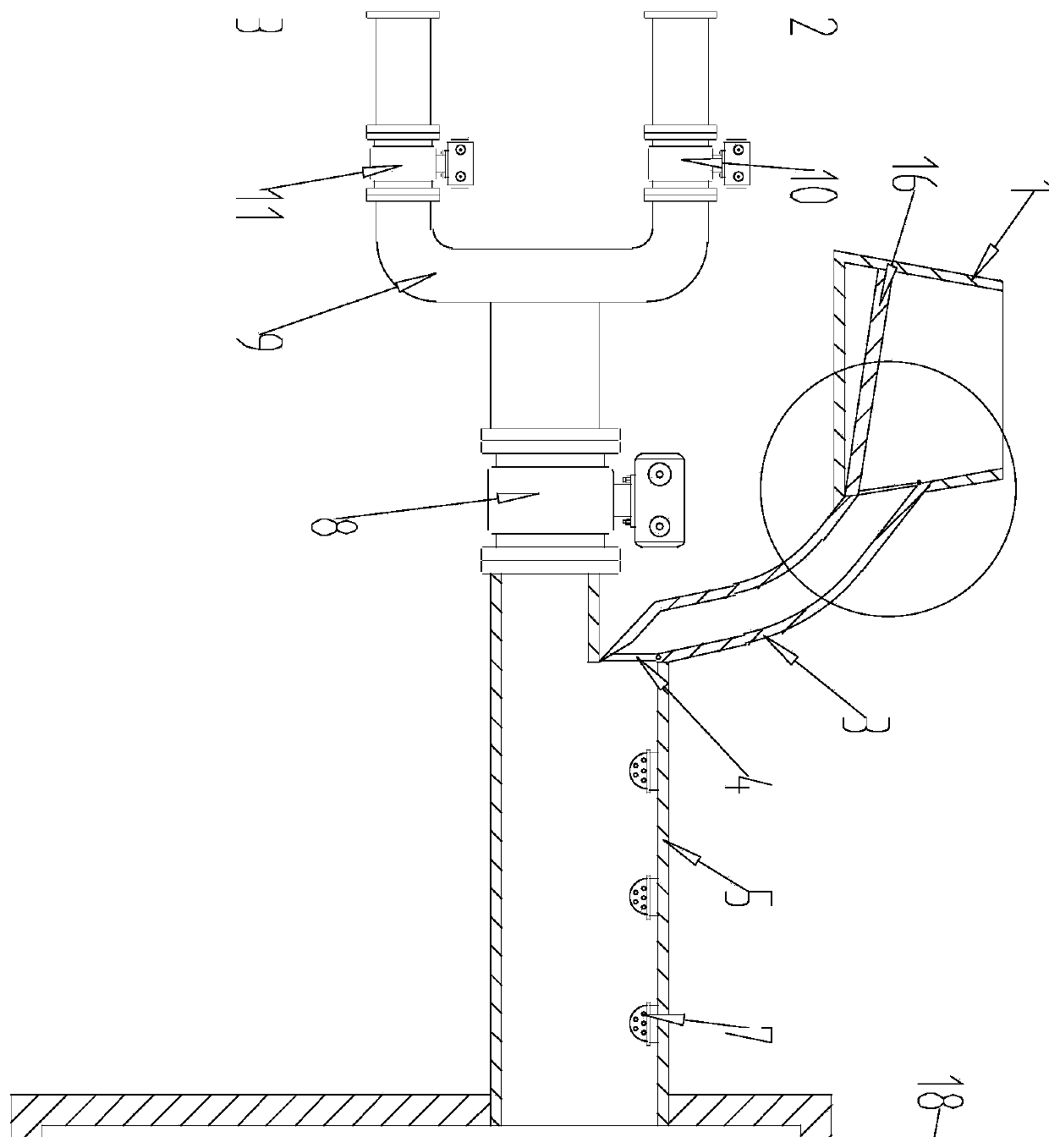

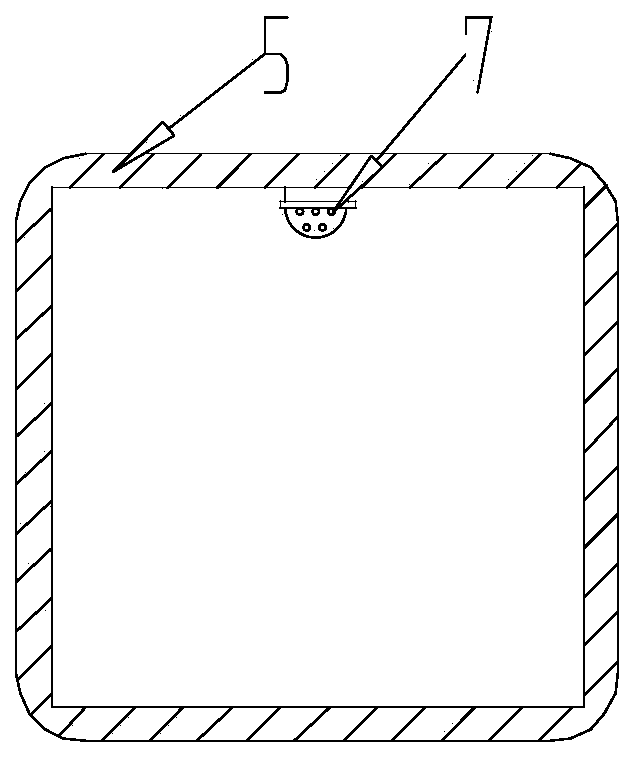

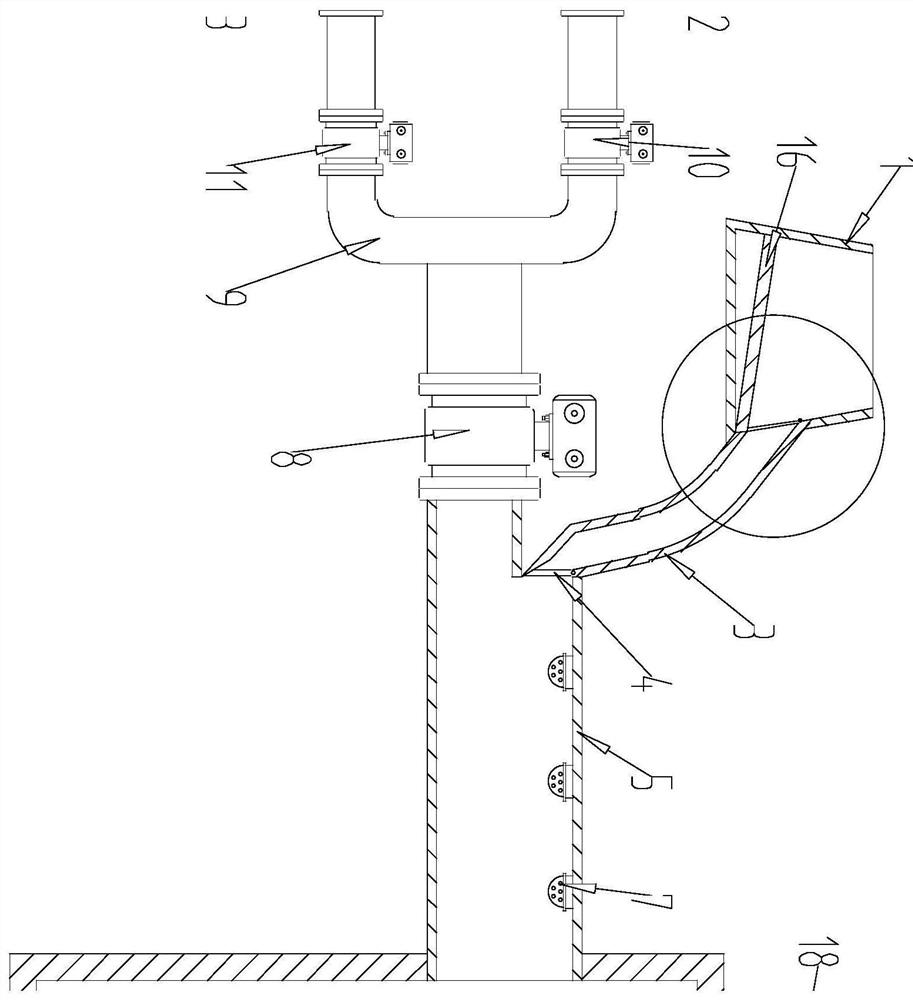

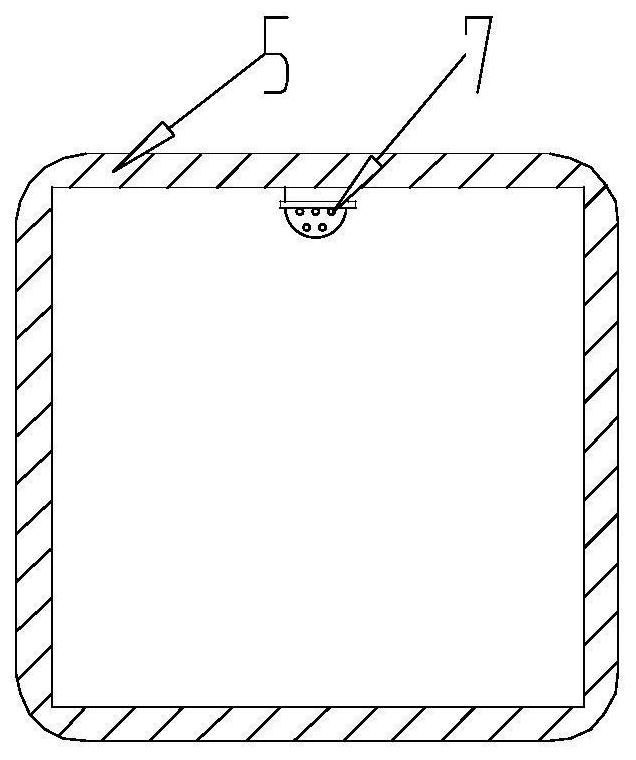

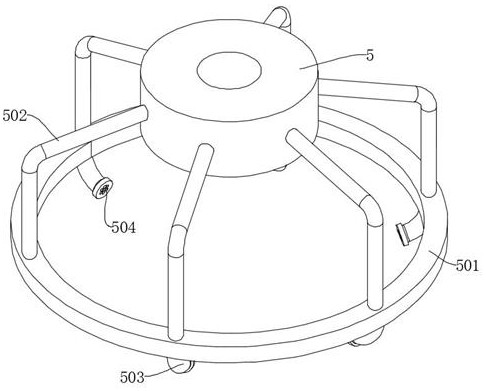

Automatic pebble coal slag discharging and collecting system of coal mill

ActiveCN110834969AReduce the possibility of spontaneous combustionGuaranteed delivery efficiencyGrain treatmentsLoading/unloadingSpontaneous combustionCold air

The invention discloses an automatic pebble coal slag discharging and collecting system of a coal mill, and relates to the technical field of pebble coal collecting devices. The automatic pebble coalslag discharging and collecting system comprises a coal hopper, and an automatic collecting structure is arranged on the coal hopper. The automatic collecting structure mainly comprises a first movable baffle, a coal dropping pipe, a second movable baffle, a purging air duct, a cold air purging structure, a collecting box and a plurality of spraying heads identical in structure. The first movablebaffle is movably mounted at one end of the coal hopper, and the coal dropping pipe is mounted at one end of the coal hopper. The second movable baffle is movably mounted at one end of the coal dropping pipe, and the purging air duct is mounted at one end of the coal dropping pipe. The cold air purging structure is mounted at one end of the purging air duct, and the collecting box is mounted at the other end of the purging air duct. The automatic pebble coal slag discharging and collecting system is simple in structure, convenient to mount and use, extremely low in maintenance cost, easy to maintain and low in failure rate, the spontaneous combustion probability of pebble coal is reduced, and safety operation of a coal pulverizing system is guaranteed.

Owner:国家能源集团泰州发电有限公司

Automatic constant-temperature lithium battery auxiliary device

ActiveCN114447410AProtection securityAvoid explosionFinal product manufactureCell temperature controlSpontaneous combustionThermodynamics

An automatic constant-temperature lithium battery auxiliary device disclosed by the present invention comprises a protection box, a charging head, a heat dissipation groove and a battery body, a protection mechanism is mounted on the inner wall of the protection box below the heat dissipation groove, a constant-temperature mechanism is mounted on the protection mechanism, and a flame-retardant mechanism is mounted on the inner wall of one side of the protection box. A limiting mechanism is installed on the surface of one side of the protection box, and a sealing rotating plate is installed in the heat dissipation groove through a rotating shaft. Through the arrangement of the structure, the constant-temperature mechanism can take away heat on the surface of the battery body, so that the battery body is in a normal-temperature charging environment, and when the temperature of the battery body exceeds the normal temperature range of the lithium battery, the switch tube is started to trigger the electromagnetic valve to work, and cooling water in the liquid box and the limiting cooling tube is guided out; the problem of high temperature of the battery body can be solved, spontaneous combustion and combustion explosion can be avoided, the charging temperature can be increased, and the viscosity of the electrolyte can be reduced.

Owner:徐州储盈电子科技有限公司

Application of ionic liquid in preparation of modified activated carbon, modified activated carbon and preparation method thereof

ActiveCN110064365BChemically stableIncreased distribution of viasOther chemical processesActivated carbonExhaust fumes

The invention relates to the technical field of adsorption materials, and specifically discloses the application of an ionic liquid in the preparation of modified activated carbon, the modified activated carbon and a preparation method thereof. The preparation method comprises the following steps: mixing the ionic liquid and activated carbon, treating at a constant temperature of 100-120° C. for 24-36 hours, and obtaining modified activated carbon through separation treatment. The modified activated carbon provided by the present invention increases the saturated adsorption capacity of organic waste gas by about 120%, increases the spontaneous ignition point by about 30°C, improves the adsorption efficiency of the modified activated carbon, increases the spontaneous ignition point, and reduces the possibility of spontaneous combustion.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of gas circulation utilization fire extinguishing system and control method in goaf

ActiveCN113250733BSpeed up the cycleAchieve recyclingMining devicesDust removalSpontaneous combustionThermodynamics

The invention discloses an anti-extinguishing system and a control method for gas circulation utilization in a goaf, including a gas transmission pipeline, a gas return pipeline, a flame retardant system, a wind flow blocking system and a gas generating device. The gas transmission pipeline includes a gas transmission main pipe and a gas transmission pipe The air branch pipe and the air return pipeline include the suction main pipe and the vertical column branch pipe, in which the gas transmission main pipe and the suction main pipe are connected by a multi-section straight pipe through a three-way valve; the flame retardant system includes a flame retardant tank, a flame retardant pipeline, The water injection pipe and the injection head are connected with a number of injection heads parallel to the flame retardant pipeline; the air flow blocking system is composed of a hydraulic support and a coal gangue pile whose gaps are sealed by foam; the gas generating device includes nitrogen gas. Production unit, nitrogen work station and gas recovery unit, this part is placed in the roadway. The whole system has simple structure, coherent working process and high efficiency, which can greatly reduce the occurrence rate of spontaneous combustion fire in the goaf.

Owner:SHANDONG UNIV OF SCI & TECH

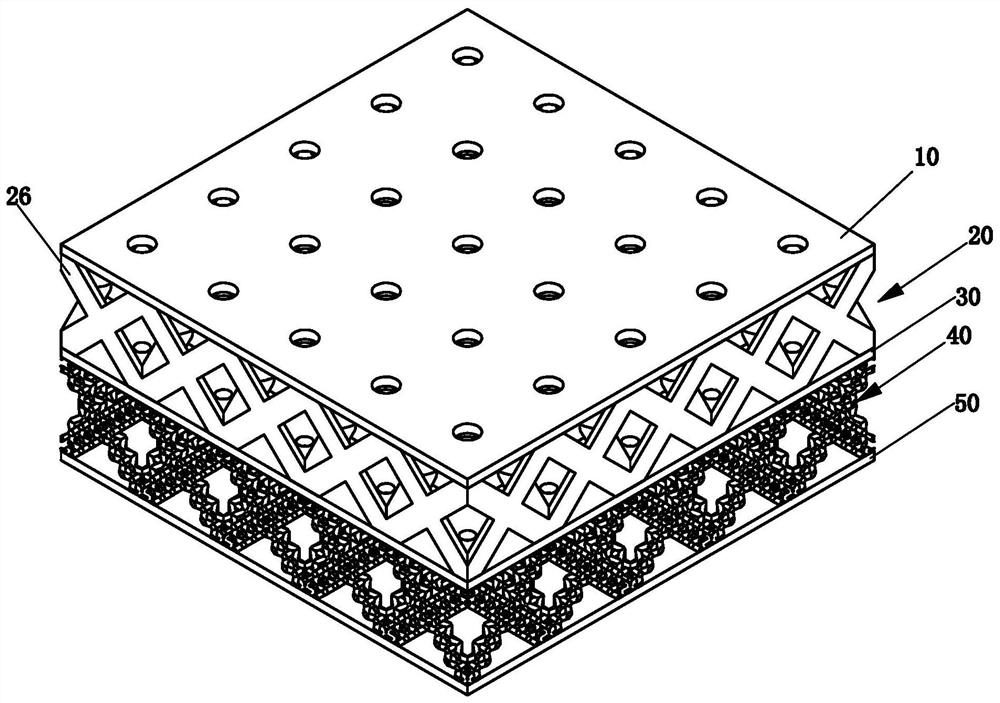

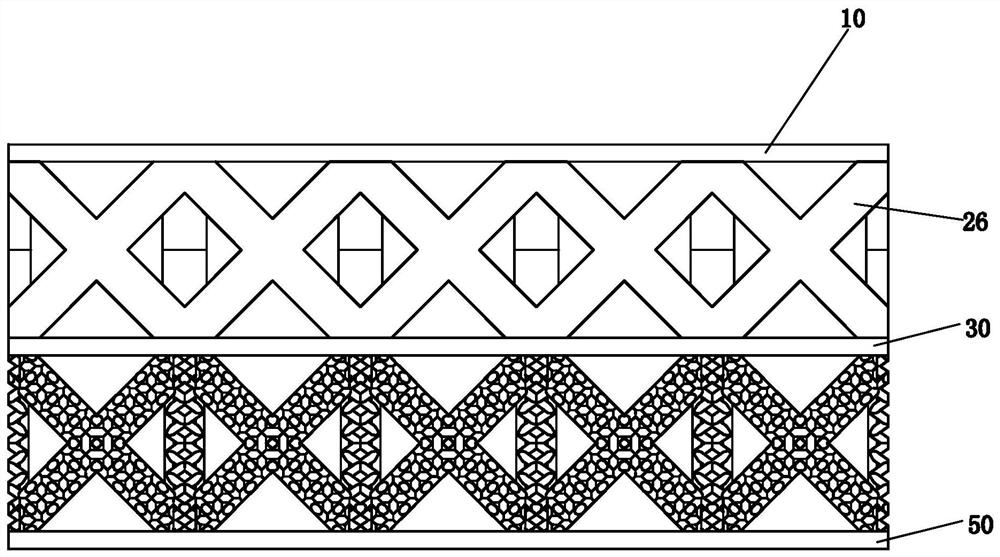

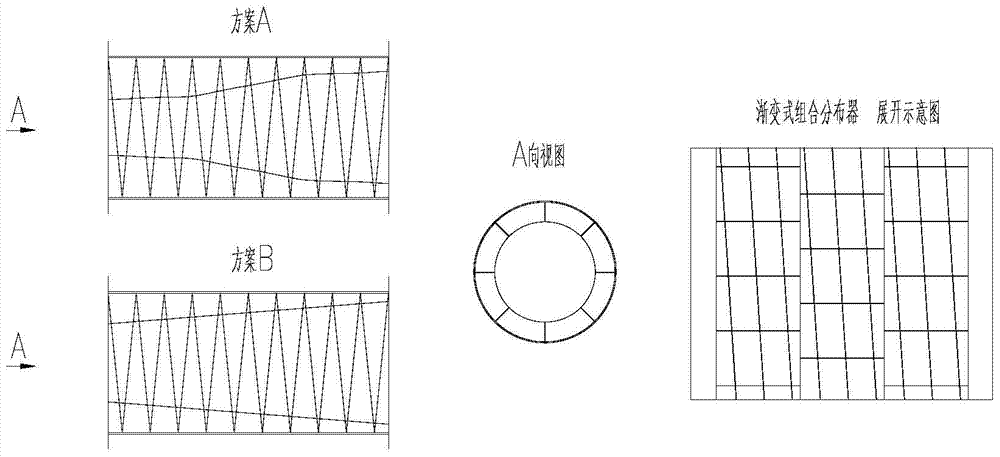

A multi-level sandwich composite structure and an automobile front panel using the structure

ActiveCN109483962BAvoid stress concentrationImprove structural rigiditySynthetic resin layered productsLaminationCross overComposite structure

The invention discloses a multi-layer sandwich-type composite structure and an automobile dash board using the same. The composite structure comprises an upper roof plate, a first sandwich-type body,and an intermediate separating plate which are successively connected. The first sandwich-type body comprises a plurality of first matrixes. A plurality of the first matrixes is arranged on a horizontal plane in periodic array. The first matrix is formed by four first crossed units. The four first crossed units are arranged along a diagonal line of four side faces of a cube, and the four first crossed units are successively connected and a first cavity is surrounded between the four first crossed units. Two neighboring first matrixes are connected through own first crossed units. The compositestructure is capable of greatly improving structural rigidity and strength, bending resistance, anti-penetration performance and different surface collision resistance. The first sandwich-type body is a single-layer lattice structure, and has higher energy absorption capability. In addition, the first cavity has a noise-reducing function.

Owner:HUAQIAO UNIVERSITY

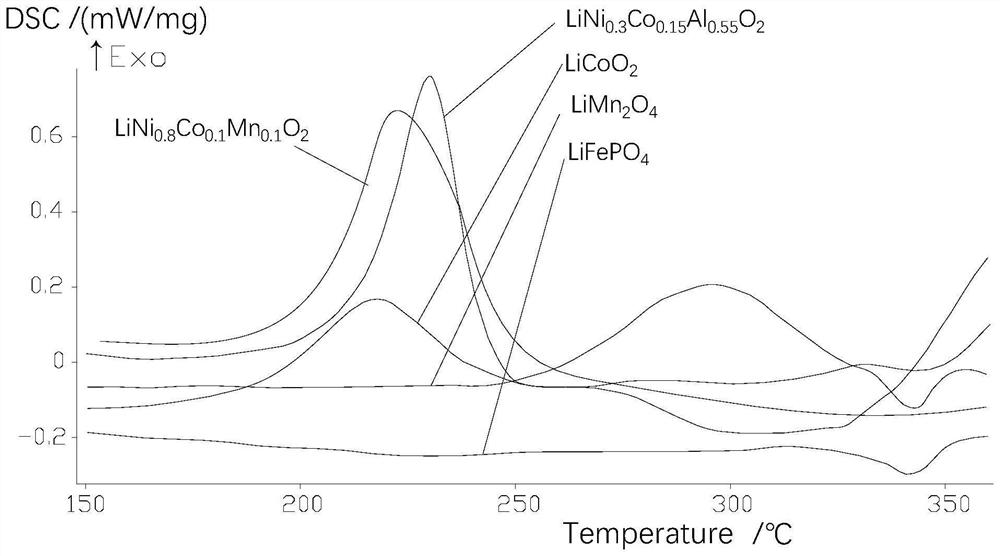

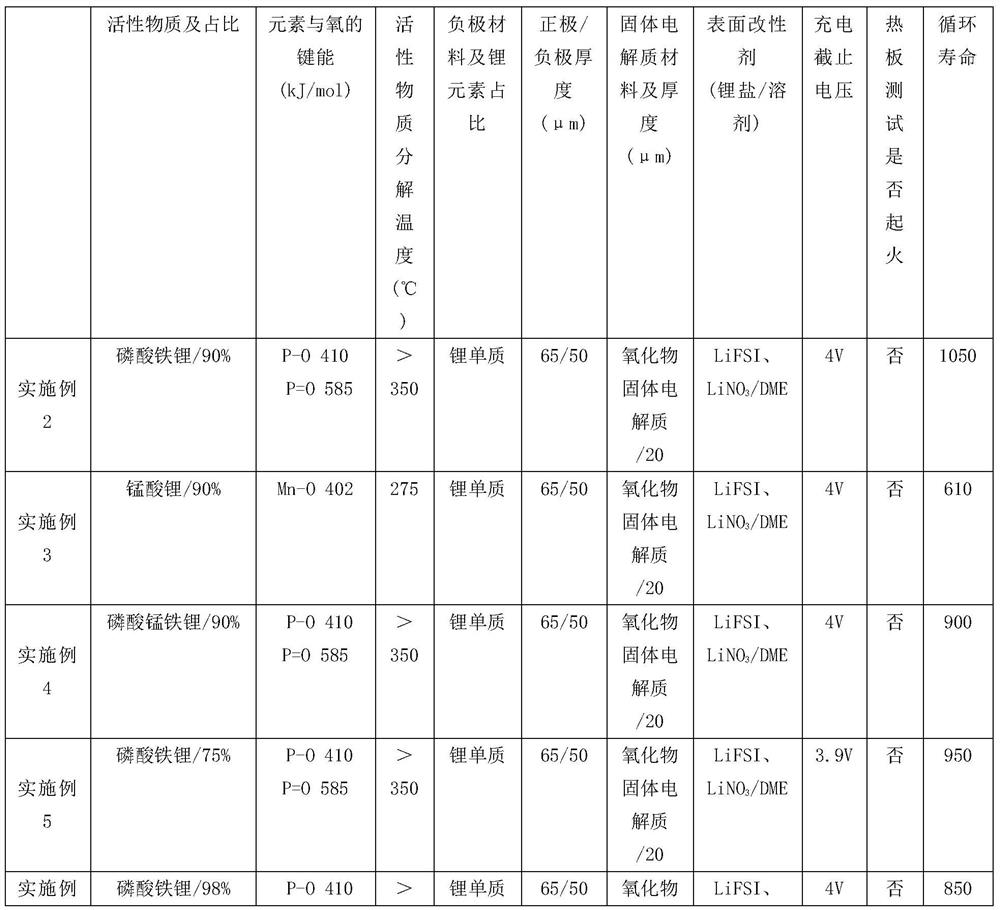

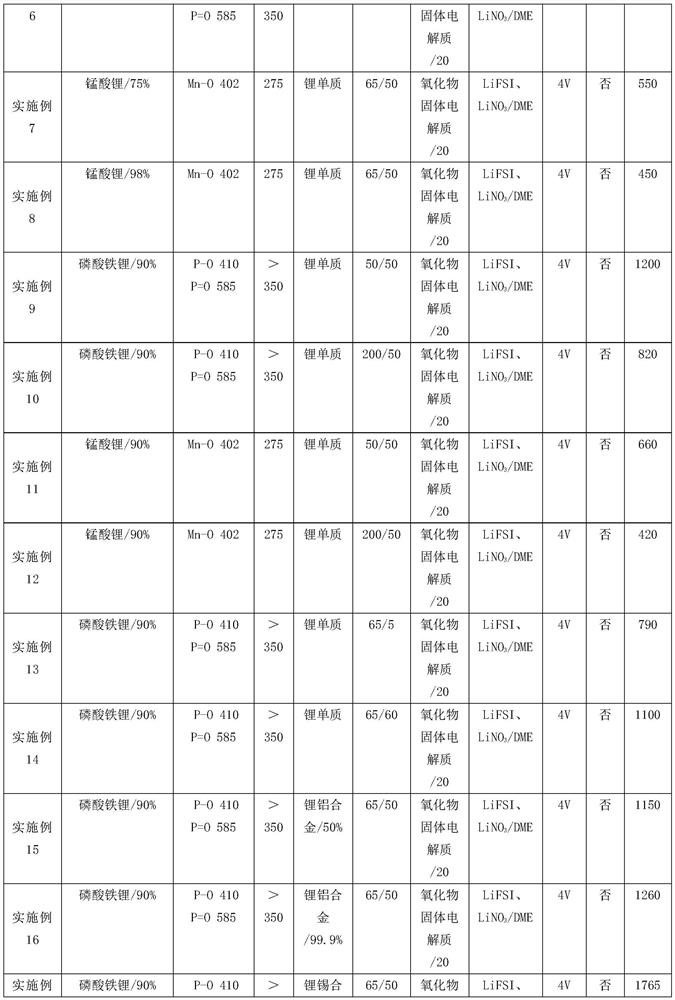

Positive electrode and high-safety and high-cyclicity lithium metal solid-state battery

PendingCN114373884AReduce oxygen evolution reactionReduce the possibility of spontaneous combustionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsElectrical batteryCyclic stability

The invention discloses a positive electrode and a lithium metal solid-state battery with high safety and high cyclicity, and belongs to the field of lithium metal solid-state batteries, the positive electrode of the lithium metal solid-state battery comprises an active substance, the bond energy of elements and oxygen in the active substance is greater than 390 kJ / mol, and the decomposition temperature of the active substance is greater than 250 DEG C. The proper active substance is screened out through the bond energy of the chemical bond and the decomposition temperature to serve as the positive electrode of the lithium metal solid-state battery, the active substance with large binding energy of elements and oxygen is selected, and the oxygen evolution reaction of the active substance in the charging process can be effectively reduced, so that the spontaneous combustion possibility of the lithium metal solid-state battery is reduced; the safety of the lithium metal solid-state battery is greatly improved; meanwhile, the selection of the active substance needs to meet the charging cut-off voltage for stabilizing the electrolyte, and the cycling stability of the battery is ensured.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Method for improving recovery rate of fully mechanized top coal caving

InactiveCN102691502BReduce the possibility of spontaneous combustionReduce overflowUnderground miningSurface miningVertical driftSpelunking

Owner:SHANDONG UNIV OF SCI & TECH

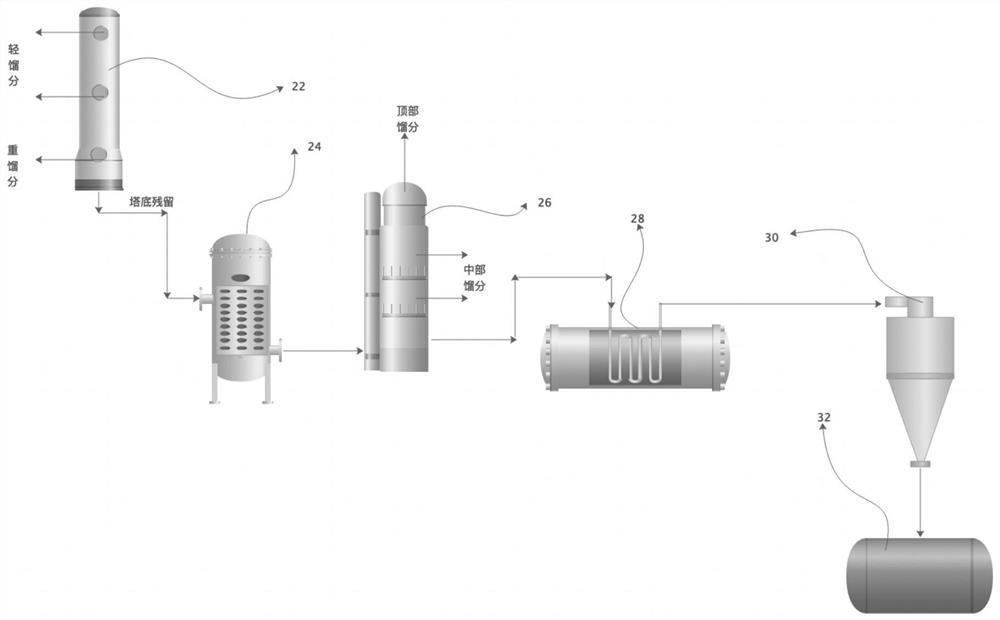

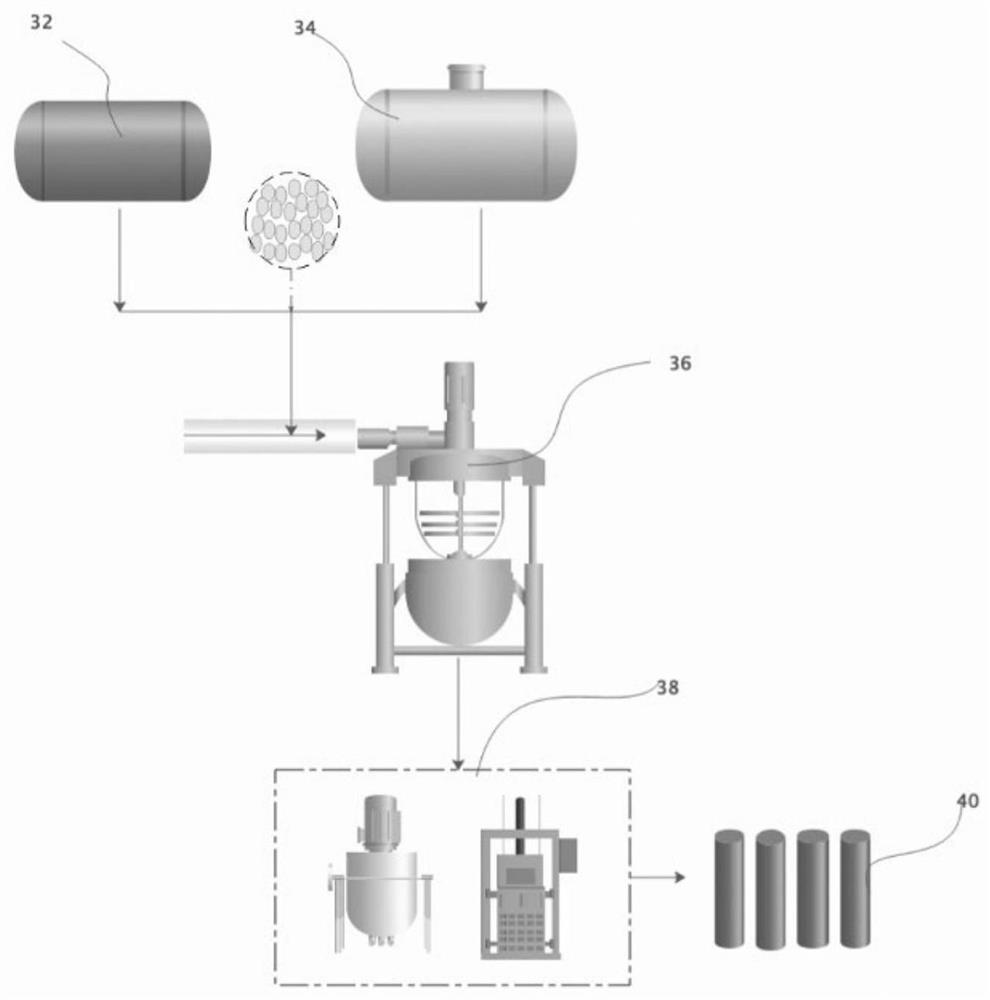

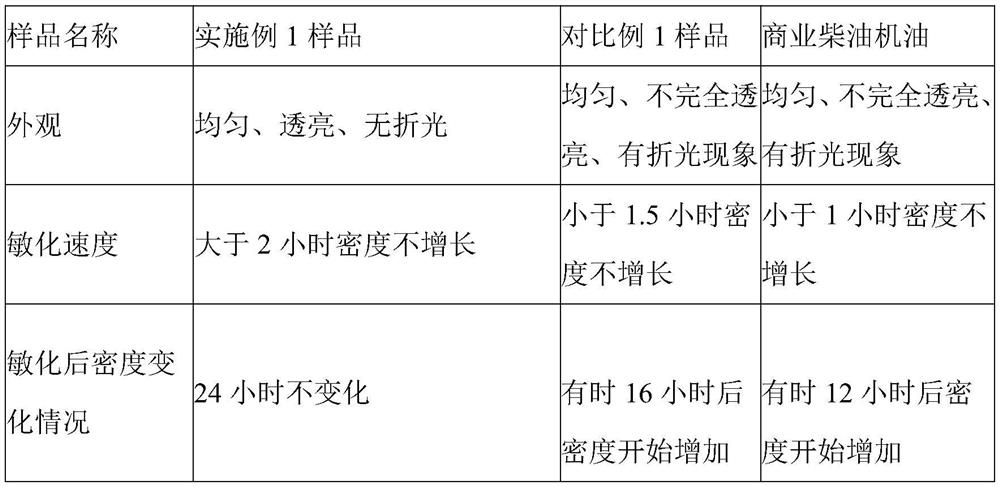

Preparation method of special oil for emulsion explosive and application of special oil in emulsion explosive

ActiveCN114874059AImprove efficiencyReduce the impactChemical industryExplosive working-up apparatusSpontaneous combustionExplosive Agents

The invention relates to a preparation method of special oil for emulsion explosives and application of the special oil for the emulsion explosives in the emulsion explosives. The influence of impurity gas and bottom slag in reduced pressure distillation is reduced, the load on reduced pressure distillation equipment is reduced, and the reduced pressure distillation efficiency is improved; the obtained special oil for the emulsion explosive is low in residual amount of sulfur and carbon, basically free water is not contained, the flash point is high, the possibility of spontaneous combustion of an oil product in the steam heating production and transportation process can be effectively reduced, and the safety coefficient is improved; meanwhile, the special oil product for the emulsion explosive does not contain an additive in engine oil blending, so that the influence of the additive on the emulsifying effect of an emulsifier is avoided, and the quality stability of an emulsion matrix is improved; the emulsion explosive prepared from the special oil for the emulsion explosive is high in density, proper in detonation velocity and good in water resistance.

Owner:新疆中科工贸有限公司

A method for producing anthracite by pyrolysis of pulverized coal in rotary furnace with gas circulation

ActiveCN104789244BHigh yieldReduce consumptionIndirect heating destructive distillationSpecial form destructive distillationAnthraciteRecovery function

The invention provides a method for pyrolysis production of anthracite in a coal powder rotary furnace. The method relates to a coal powder dust removing rotary drying furnace system, an external-heating rotary furnace pyrolysis system with a coal gas circulation function, a rotary cooling passivation system with a heat recovery function, and an oil gas recovering system, wherein the coal powder dust removing rotary drying furnace system is used for heating coal powder to 110 to 280 DEG C and removing coal dust of which the particle size is smaller than 0.2 mm; drying water is recovered and fed to a downstream spiral cooling machine to be used for anthracite cooling and humidification; the coal dust obtained after separation is fed to a coal gas generating system to generate fuel, namely coal gas; after dust removing, coal is sent to a downstream rotary pyrolysis system for pyrolysis; high-temperature anthracite is generated, and cooled; the cooled anthracite is passivated at a middle-low temperature; the passivated anthracite is cooled in the spiral cooling machine; water is sprayed on the cooled passivated anthracite for humidification; the humidified anthracite is sent out; high-temperature oil gas produced in the process enters the oil gas recovering system to obtain coal tar, pyrolyzed water and coal gas. Part of the produced pyrolyzed coal gas returns to the pyrolysis furnace after preheating in a circulating manner, while the other part of the produced pyrolyzed coal gas is sent out.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

A device for preparing nano powder by electric explosion method

ActiveCN106807310BChange rotation speedAchieve straightening and conveyingEnergy based chemical/physical/physico-chemical processesMicroballoon preparationElectricityNanoparticle

The invention discloses equipment for preparing nano powder by an electrical explosion method, and belongs to the field of nanomaterial preparation. The equipment aims at solving the problem that the conventional nano powder production equipment has a strict requirement for an insulating structure and an insulating material of a high-voltage part. The equipment comprises a nano powder reaction mechanism, an electrical explosion generation mechanism, a wire feeding mechanism matched with the nano powder reaction mechanism, an air cooler, a first connecting tube, a first insulating tube, a second connecting tube, a second insulating tube and a third connecting tube. According to the equipment, instant high voltage is generated by electrodes, so that materials in an explosion reaction cavity react to generate corresponding nano particles. Due to an improvement of a structure, the working voltage of the equipment is equal to or lower than 25KV, and a high-voltage part has a very low requirement for a high-voltage structure and a withstand voltage material. In addition, raw materials of the equipment are filamentary materials and non-insulators, so that the equipment has the characteristics of wide raw material source and high adaptability, and has good universality for various filamentary non-insulator materials.

Owner:四川弘博新材科技股份有限公司

A rotary kiln low-rank pulverized coal pyrolysis upgrading method with gas circulation

ActiveCN104762097BReduce coal dust contentImprove qualitySpecial form destructive distillationGranularityCoal dust

The invention provides a rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation. The rotary furnace low-order powdered coal pyrolysis upgrading method comprises the following steps: heating and drying raw material powdered coal with the granularity less than or equal to 30mm to be 110-280 DEG C in a low-order powdered coal rotary drying system with dust collection, and removing 85% of coal dust with the granularity less than 0.5mm in the powdered coal; feeding the dried coal with the granularity of 0.5-30mm to a downstream rotary pyrolysis system to react at 500-700 DEG C so as to generate upgraded coal and a high-temperature oil gas; feeding the high-temperature upgraded coal to a rotary cooling passivating furnace for primary cooling and medium / low temperature passivation, further cooling by using a spiral cooling machine, spraying water, and discharging out the product; feeding the high-temperature oil gas into an oil gas recycling system, and performing temperature reduction separation, thereby obtaining coal tar, pyrolysis water and pyrolysis coal gas; preheating a part of the pyrolysis coal gas, circulating back to the pyrolysis furnace, and discharging out the rest part of the pyrolysis coal gas.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

a transformer

ActiveCN113192736BIncrease pressureAvoid contactTransformers/inductances coolingTransformers/inductances casingsSpontaneous combustionTransformer

The invention discloses a transformer and belongs to the technical field of transformers. A transformer, comprising an installation box, further comprising: an electrical assembly detachably connected to the installation box, wherein the electrical assembly includes a casing, and a heat sink is arranged in the casing, and a heat sink is fixedly connected to the heat sink. Windings, the top of the housing is provided with terminals, the terminals are electrically connected to the windings; the shunt box fixedly connected to the inner wall of the housing is used to spray dry powder to the windings; the shunt box arranged in the installation box Ring; the connecting block arranged in the installation box; the present invention automatically uses dry powder to extinguish the fire of the electrical components when they spontaneously ignite, preventing the electrical components from continuing to burn and causing a fire, and by collecting rainwater, the rainwater is used to reduce the temperature inside the installation box , so as to reduce the possibility of spontaneous combustion of electrical components, and the water in the water chamber can absorb the vibration waves generated by the electrical components, thereby reducing noise.

Owner:江苏龙创电气有限公司

Coal mine connecting roadway and sealing method thereof

ActiveCN104179527BImprove poor plasticityImprove sealingMining devicesSpontaneous combustionCement cure

The invention discloses a coal mine tie roadway and a sealing method thereof. The coal mine tie roadway includes a solidified cement layer and a foamed cement layer vertically arranged in the coal mine tie wayway, and the solidified cement layer includes a first solidified cement layer and a foamed cement layer. The second solidified cement layer, the foamed cement layer is arranged between the first solidified cement layer and the second solidified cement layer, and the first solidified cement layer is also provided with a pouring hole for pouring foamed cement hole. The present invention uses less heat release after physical expansion and relatively cheap foamed cement material to fill the foamed cement layer, which can not only effectively reduce the sealing cost of coal mine connecting lanes, improve sealing efficiency, and reduce the possibility of spontaneous combustion of floating coal at the top of connecting lanes It also solves the problem of poor plasticity of the foamed cement by setting the solidified cement layer on both sides of the foamed cement layer, thereby helping to improve the sealing performance of the foamed cement layer.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A hot air vulcanization equipment

ActiveCN106003497BReduce the possibility of spontaneous combustionImprove securityCombustorCombustion chamber

The invention discloses hot air vulcanization equipment. The hot air vulcanization equipment comprises a vulcanization tank, and a vulcanization conveying chain is arranged in the vulcanization tank. A vulcanization line feeding inlet combustor and a vulcanization line discharging outlet combustor are arranged on the top of the vulcanization tank. A vulcanization line feeding inlet combustion engine is arranged on one side of the vulcanization line feeding inlet combustor, and a vulcanization line feeding inlet circulating fan is arranged on the other side of the vulcanization line feeding inlet combustor. A vulcanization line feeding inlet air supply channel is arranged below the vulcanization line feeding inlet circulating fan. A vulcanization line air return channel is arranged in the vulcanization tank. A vulcanization line discharging outlet combustion engine is arranged on one side of the vulcanization line discharging outlet combustor, and a vulcanization line discharging outlet circulating fan is arranged on the other side of the vulcanization line discharging outlet combustor. A vulcanization line discharging outlet air supply channel is arranged below the vulcanization line discharging outlet circulating fan. A waste air exhaust fan is arranged in a discharging outlet of the vulcanization tank. The hot air vulcanization equipment has the beneficial effects that the production safety coefficient is high, cost is low, the vulcanization time is short, the vulcanization efficiency is high, and the vulcanization effect is good.

Owner:GUIZHOU DAZIRAN TECH

A Coal Pulverizer Pebble Coal Automatic Slagging Collection System

ActiveCN110834969BReduce the possibility of spontaneous combustionGuaranteed delivery efficiencyGrain treatmentsLoading/unloadingCold airSlag

Owner:国家能源集团泰州发电有限公司

Method and device for preparing flake metal powder by dry ball milling

The invention provides a method for dry-type ball milling to prepare flake metal powder, comprising: uniformly mixing metal raw material powder and ball milling aids, and putting steel balls in proportion to ball milling in a new type of closed roller ball mill, and the ball milling process is circulated through cooling water The temperature of the ball mill is controlled by the system, and the ball mill atmosphere in the cylinder is adjusted by the ball mill atmosphere control system; the discharge adopts a closed discharge system, and a certain pressure of inert gas is introduced to start the exhaust fan and the ball mill, and the metal powder ground in the ball mill is blown and sucked. Blow and suck it out; put it into the dispersing equipment to disperse, and then classify it through the airflow grading equipment to get the finished product. And a device for realizing the above method. The method of the present invention has a high degree of automation in the whole process, no steel ball turnover, greatly reduces the labor intensity and workload of workers, and in addition has good sealing and cooling effects, no dust pollution, avoids the phenomenon of spontaneous combustion of powder oxidation in the process of powder discharge, and has a high yield Large, the production efficiency is greatly improved.

Owner:SHENZHEN NONFEMET TECH

Transformer

ActiveCN113192736AIncrease pressureAvoid contactTransformers/inductances coolingTransformers/inductances casingsSpontaneous combustionTransformer

The invention discloses a transformer, and belongs to the technical field of transformers. The transformer comprises an installation box and further comprises an electrical assembly detachably connected to the installation box, the electrical assembly comprising a shell, a cooling fin being arranged in the shell, a winding being fixedly connected to the cooling fin, a wiring terminal being arranged at the top of the shell, and the wiring terminal being electrically connected with the winding; a shunting box fixedly connected to the inner wall of the shell and used for spraying dry powder to a winding; a shunting ring arranged in the installation box; and a connecting block arranged in the installation box. According to the invention, dry powder is automatically utilized to extinguish fire when the electrical component is spontaneously combusted, fire disasters caused by continuous combustion of the electrical component are prevented, and rainwater is collected and utilized to reduce the temperature in the mounting box, so that the possibility of spontaneous combustion of the electrical component is reduced; and the water in the water cavity can absorb vibration waves generated when the electrical assembly works, so that the noise is reduced.

Owner:江苏龙创电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com