A kind of gas circulation utilization fire extinguishing system and control method in goaf

A technology of gas circulation and gobs, applied in the field of fire prevention and extinguishing systems, can solve the problems of inability to quickly reduce the oxygen concentration of gobs, low utilization rate of nitrogen gas, and slow diffusion of nitrogen gas, so as to speed up the gas circulation speed, improve the utilization rate, The effect of reducing oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

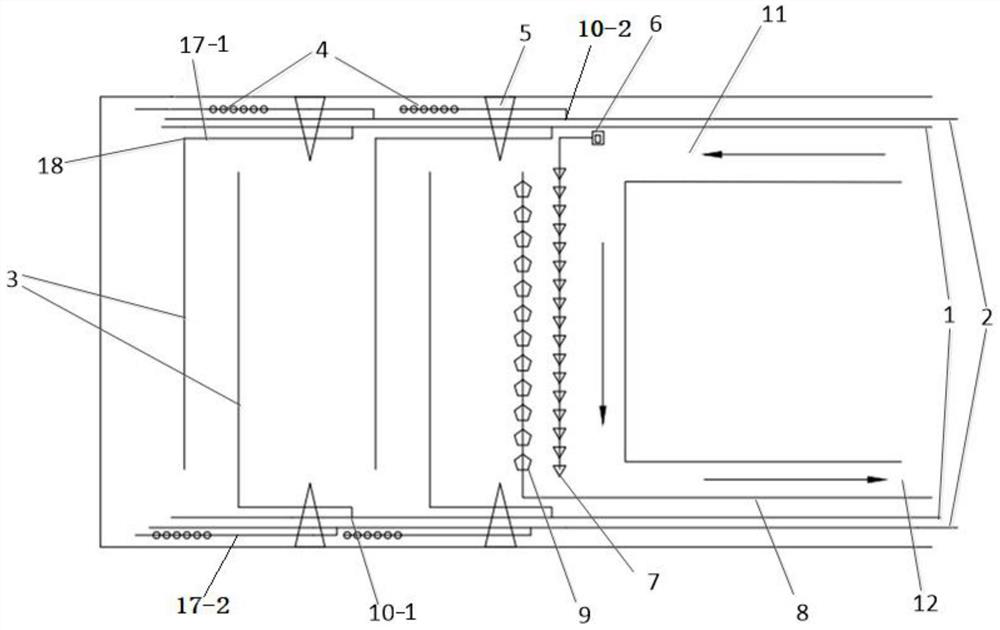

[0028] like figure 1 As shown, an anti-extinguishing system for gas recycling in a goaf includes a gas transmission pipeline, a gas return pipeline, a flame retardant system, a wind flow blocking system and a gas generating device.

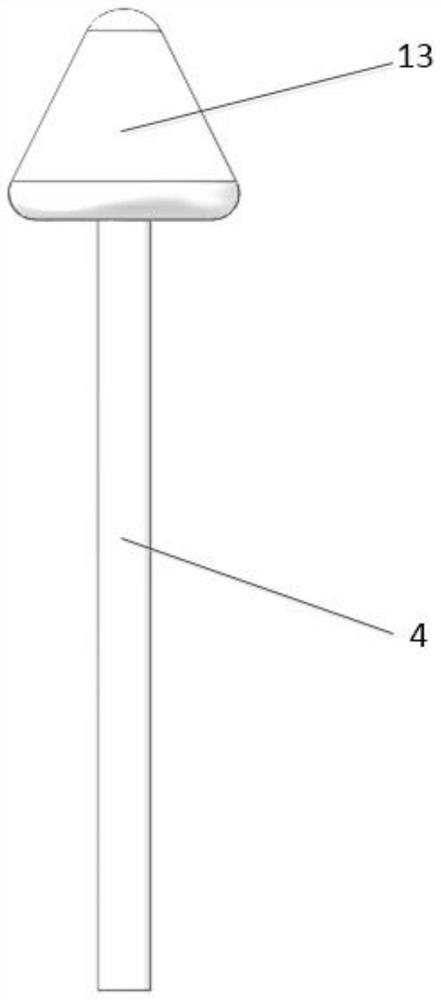

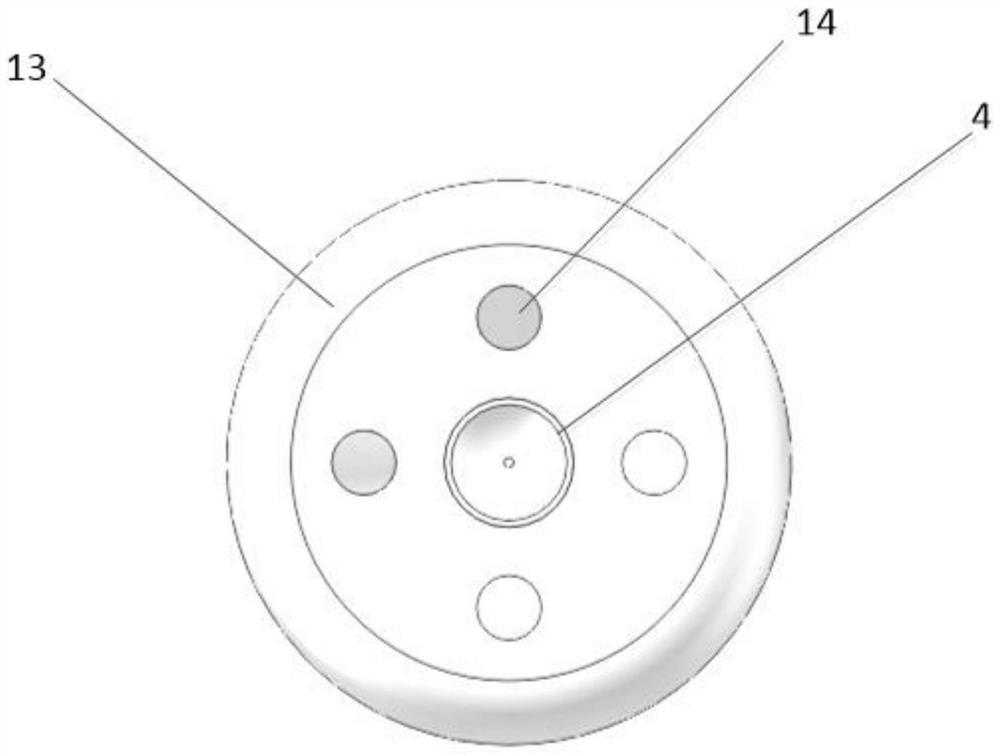

[0029] The gas transmission pipeline includes a gas transmission main pipe 1 and a gas transmission branch pipe 3. The gas transmission main pipe 1 is respectively arranged in the air inlet road 11 and the return air road 12 of the fully mechanized mining face. The three-way valves 10-1 are connected together, and the third interface of each first three-way valve 10-1 is connected to the gas transmission branch pipe 3 through the first L-shaped short pipe 17-1 and the right-angle joint 18. The empty area is arranged in the width direction, and each gas transmission branch pipe 3 is distributed at intervals. The horizontal distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com