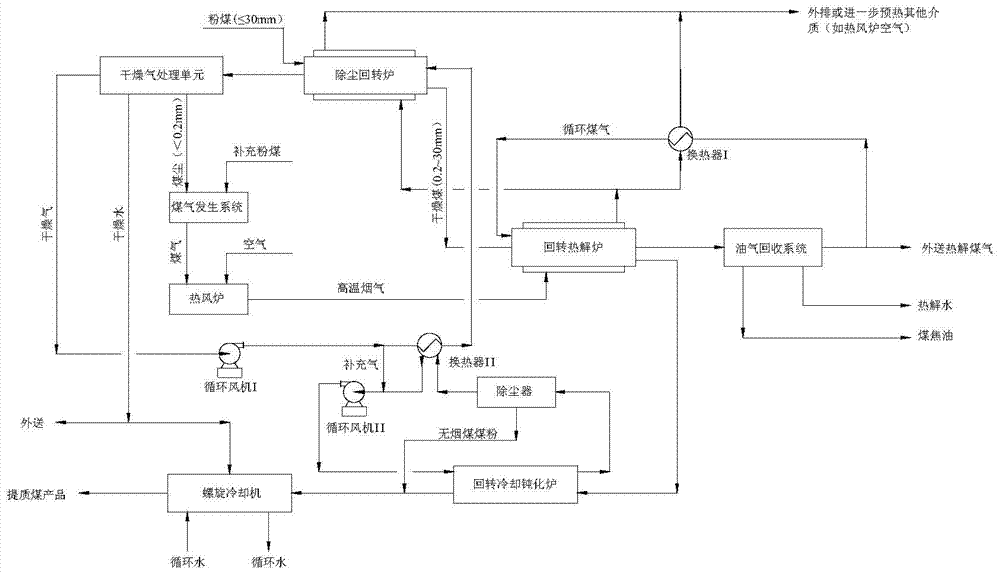

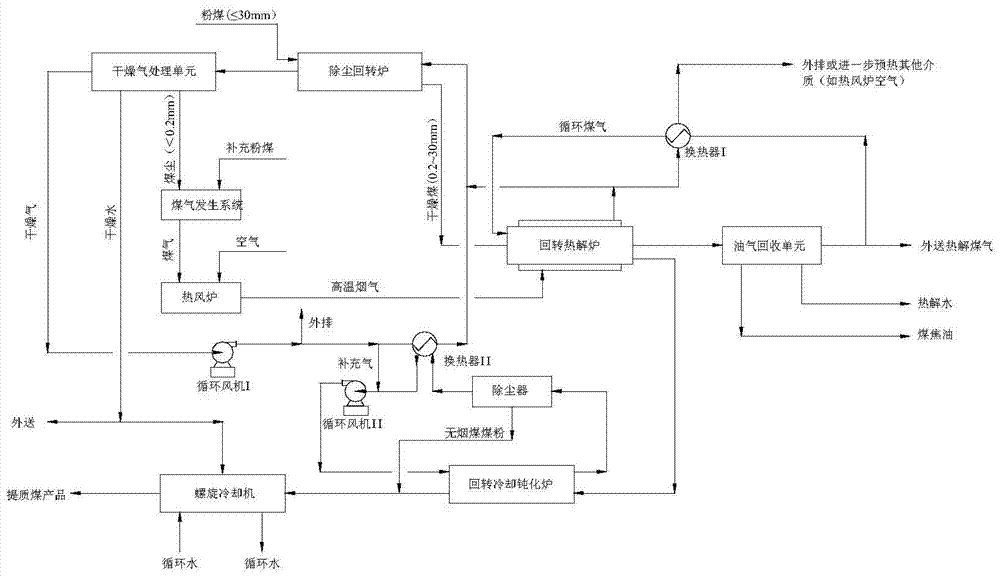

A method for producing anthracite by pyrolysis of pulverized coal in rotary furnace with gas circulation

A technology for pyrolysis of anthracite and coal, used in coke ovens, indirect heating dry distillation, special forms of dry distillation, etc., which can solve the problems of poor utilization of heat and low system energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Send 2 tons of Shenfu pulverized coal (0-30mm) to the dedusting rotary drying furnace continuously, and the flue gas from the rotary pyrolysis furnace with a temperature of 600°C is introduced into the jacket as a heat source, and the dust is dedusted in the rotary drying furnace at the same time The clean flue gas (O 2 Content 3%) is used as dedusting gas. In the dedusting rotary drying furnace, the pulverized coal is heated to 250°C, and the water content after being treated is 0wt%. After dedusting, the pulverized coal enters the rotary pyrolysis furnace through the discharge valve for pyrolysis, producing high-temperature oil gas and anthracite: the anthracite enters the rotary cooling passivation furnace, recovers high-level heat and conducts medium-low temperature passivation, and then sends it to the spiral cooler Spray water to further cool and humidify, and the humidified anthracite (H 2 O content 7wt%) sends out as the product. The high-temperature oil and ...

Embodiment 2

[0087] 6 tons of Shenfu pulverized coal (0-30mm) are continuously sent to the dedusting rotary drying furnace, and the clean flue gas (O 2 Content 2%) as dust removal gas and heat source. In the dedusting rotary drying furnace, the pulverized coal is heated to 200°C, and the water content after treatment is 1.5wt%. The pulverized coal after dust removal enters the rotary pyrolysis furnace through the discharge valve for pyrolysis to produce high-temperature oil gas and anthracite: the anthracite enters the rotary cooling passivation furnace, recovers high-level heat and passivates, and sends it to the spiral cooler for further cooling by spraying water , humidification, humidified anthracite (H 2 O content 7wt%) sends out as the product. The high-temperature oil and gas enter the oil and gas recovery system, and perform unit operations such as dust removal, cooling, and separation to obtain coal tar, pyrolysis gas and pyrolysis water; among them, part of the pyrolysis gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com