Deforming contact type fabric fluff removal device

A contact-type, fluffy technology, applied in the field of garment processing, can solve the problems of fabric wrinkles, increase production costs, and fluff attached, and achieve the effect of promoting sinking, reducing the possibility, and improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

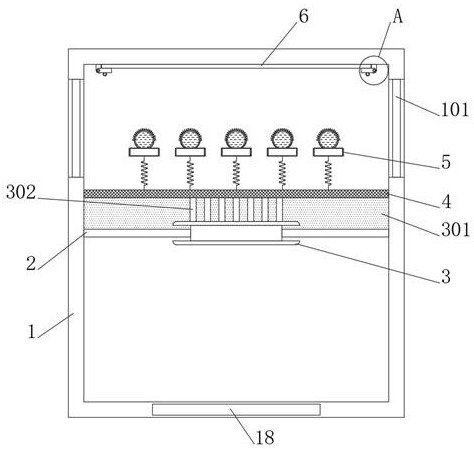

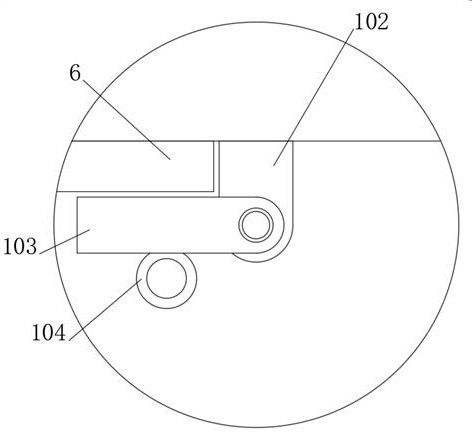

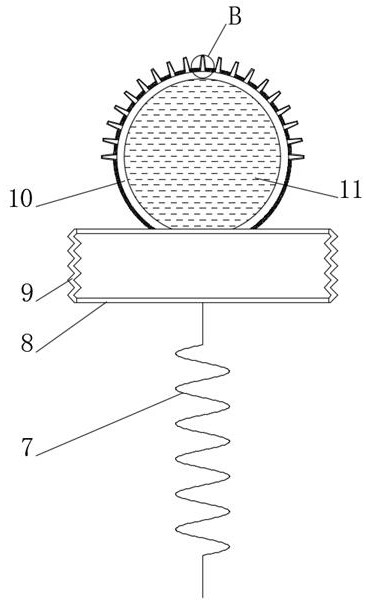

[0042] see Figure 1-4 , a deformation contact type cloth fluff removal device, comprising a fluff removal box 1, the inner wall of the fluff removal box 1 is fixedly connected with a partition plate 2, and a semiconductor refrigeration chip 3 is embedded in the partition plate 2, and the inner wall of the fluff removal box 1 It is fixedly connected with a load-bearing filter screen 4 positioned on the upper side of the partition plate 2. The upper end of the load-bearing filter screen 4 is fixedly connected with a plurality of evenly distributed velvet picking devices 5. The top of the fluff removal box 1 is provided with a cloth 6. The velvet picking device 5 includes The metal connecting rope 7 fixedly connected with the carrying filter 4, the upper end of the metal connecting rope 7 is fixedly connected with a lifting air bag, and the lifting air bag includes a pair of heat-conducting discs 8 distributed up and down, and an annular bag is fixedly connected between the two h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com