Preparation method of special oil for emulsion explosive and application of special oil in emulsion explosive

A technology for emulsifying explosives and special oil, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of unsatisfactory emulsification effect of explosives, low flash point of the oil phase of emulsified explosives, unqualified explosives, etc., to avoid the influence of emulsification effect , high flash point, suitable explosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

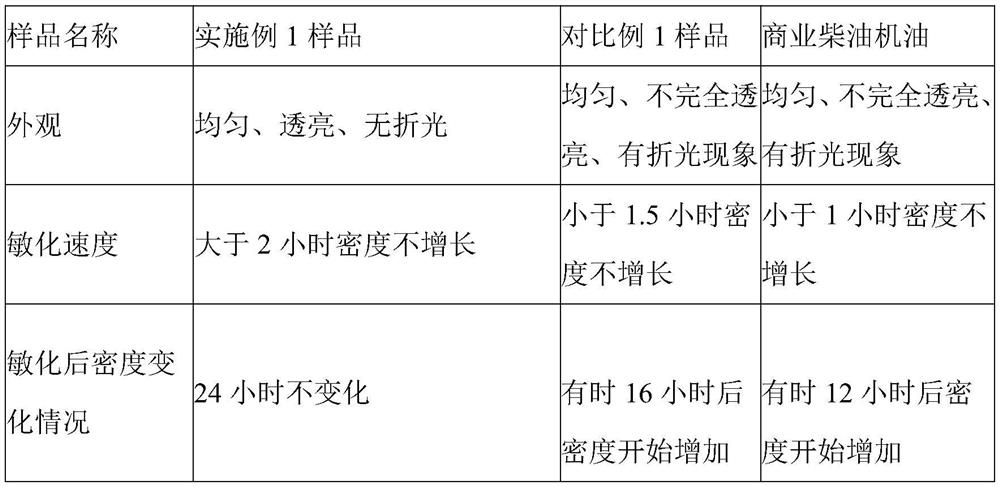

Examples

Embodiment 1

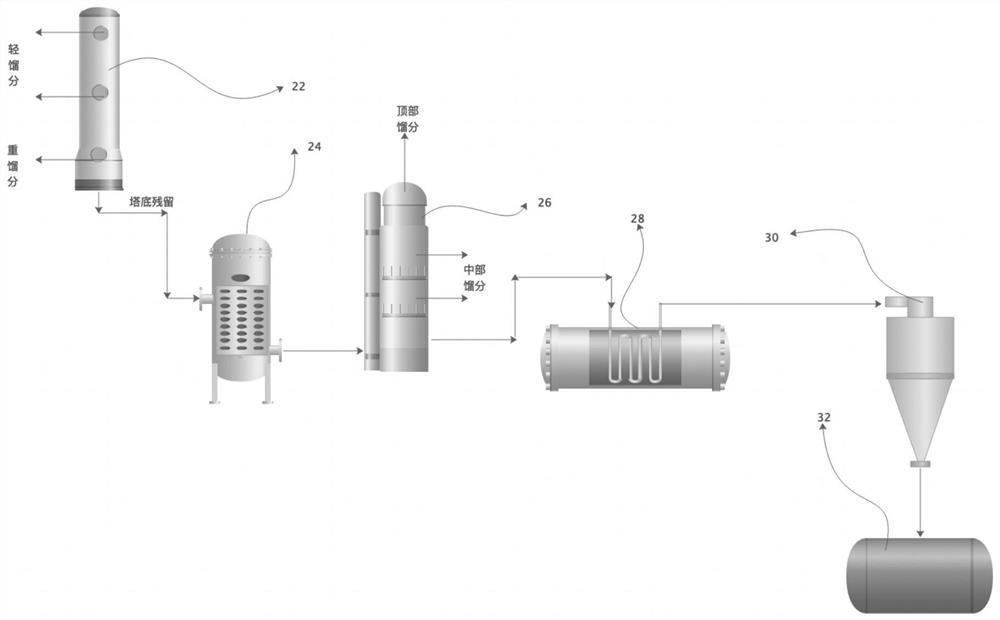

[0047] A preparation method of special oil for emulsion explosives, comprising the following steps:

[0048] Step 1: The base crude oil is heated in an atmospheric distillation tower, the components of the base crude oil are separated, the obtained light fractions and heavy fractions are separated from the middle section of the atmospheric distillation tower, and the bottom residue is obtained at the same time; the heavy fractions are used as intermediate oil fractions Carry out circulation; atmospheric distillation temperature is controlled at 360 ℃;

[0049] Step 2: the residue at the bottom of the tower is pumped into a plate filter tower to remove heavy impurities to obtain a filtered residue;

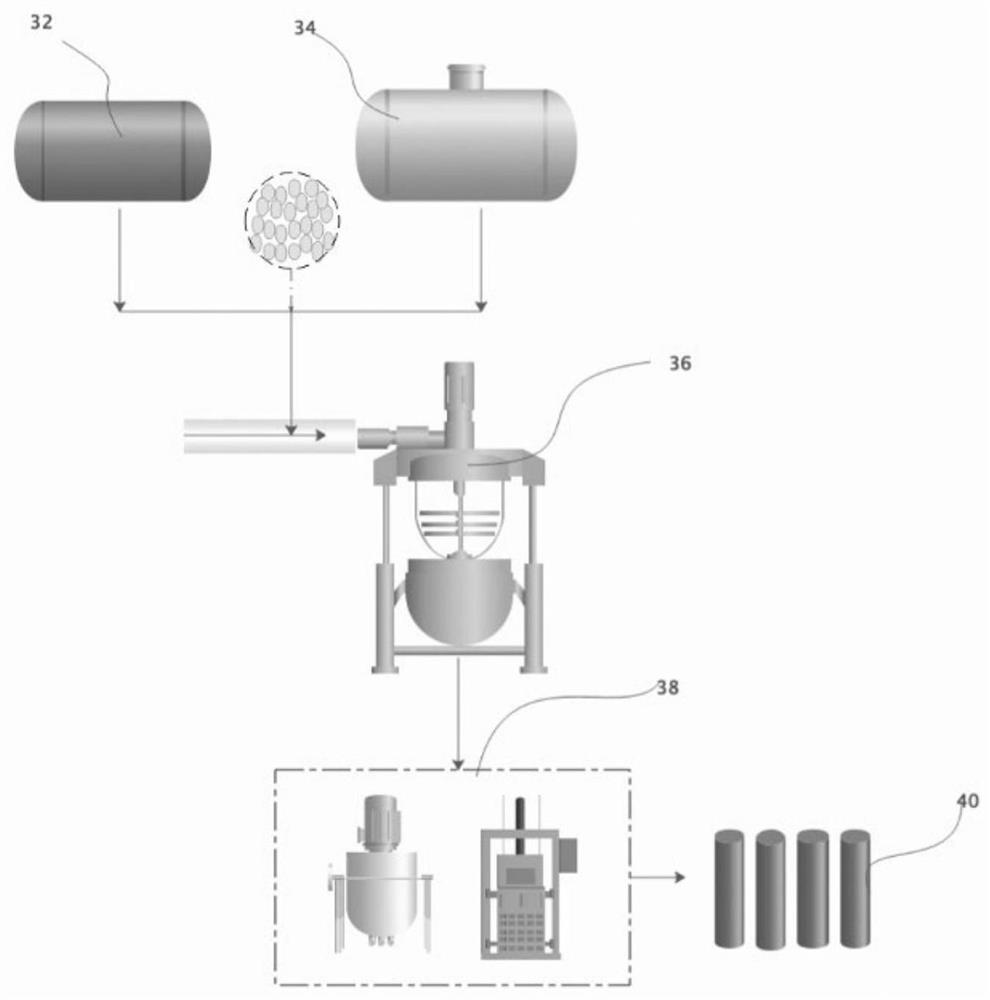

[0050] Step 3: The residue obtained in step 2 enters the vacuum distillation column for vacuum distillation separation, the light fraction escapes directly from the top of the column, part of the fraction is separated in the middle of the column, and the oil and gas special for emu...

Embodiment 2

[0054] A preparation method of special oil for emulsion explosives, comprising the following steps:

[0055] Step 1: The base crude oil is heated in an atmospheric distillation tower, the components of the base crude oil are separated, the obtained light fractions and heavy fractions are separated from the middle section of the atmospheric distillation tower, and the bottom residue is obtained at the same time; the heavy fractions are used as intermediate oil fractions Carry out circulation; atmospheric distillation temperature is controlled at 400 ℃;

[0056] Step 2: the residue at the bottom of the tower is pumped into a plate filter tower to remove heavy impurities to obtain a filtered residue;

[0057] Step 3: The residue obtained in step 2 enters the vacuum distillation column for vacuum distillation and separation, the light fraction escapes directly from the top of the column, part of the fraction is separated in the middle of the column, and the oil and gas special for...

Embodiment 3

[0061] A preparation method of special oil for emulsion explosives, comprising the following steps:

[0062] Step 1: The base crude oil is heated in an atmospheric distillation tower, the components of the base crude oil are separated, the obtained light fractions and heavy fractions are separated from the middle section of the atmospheric distillation tower, and the bottom residue is obtained at the same time; the heavy fractions are used as intermediate oil fractions Carry out circulation; atmospheric distillation temperature is controlled at 360 ℃;

[0063] Step 2: the residue at the bottom of the tower is pumped into a plate filter tower to remove heavy impurities to obtain a filtered residue;

[0064] Step 3: The residue obtained in step 2 enters the vacuum distillation column for vacuum distillation and separation, the light fraction escapes directly from the top of the column, part of the fraction is separated in the middle of the column, and the oil and gas special for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com