Automatic pebble coal slag discharging and collecting system of coal mill

An automatic slag discharge and collection system technology, which is applied in the directions of transportation and packaging, loading/unloading, grain processing, etc., to achieve the effects of ensuring efficiency, reducing pollution, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

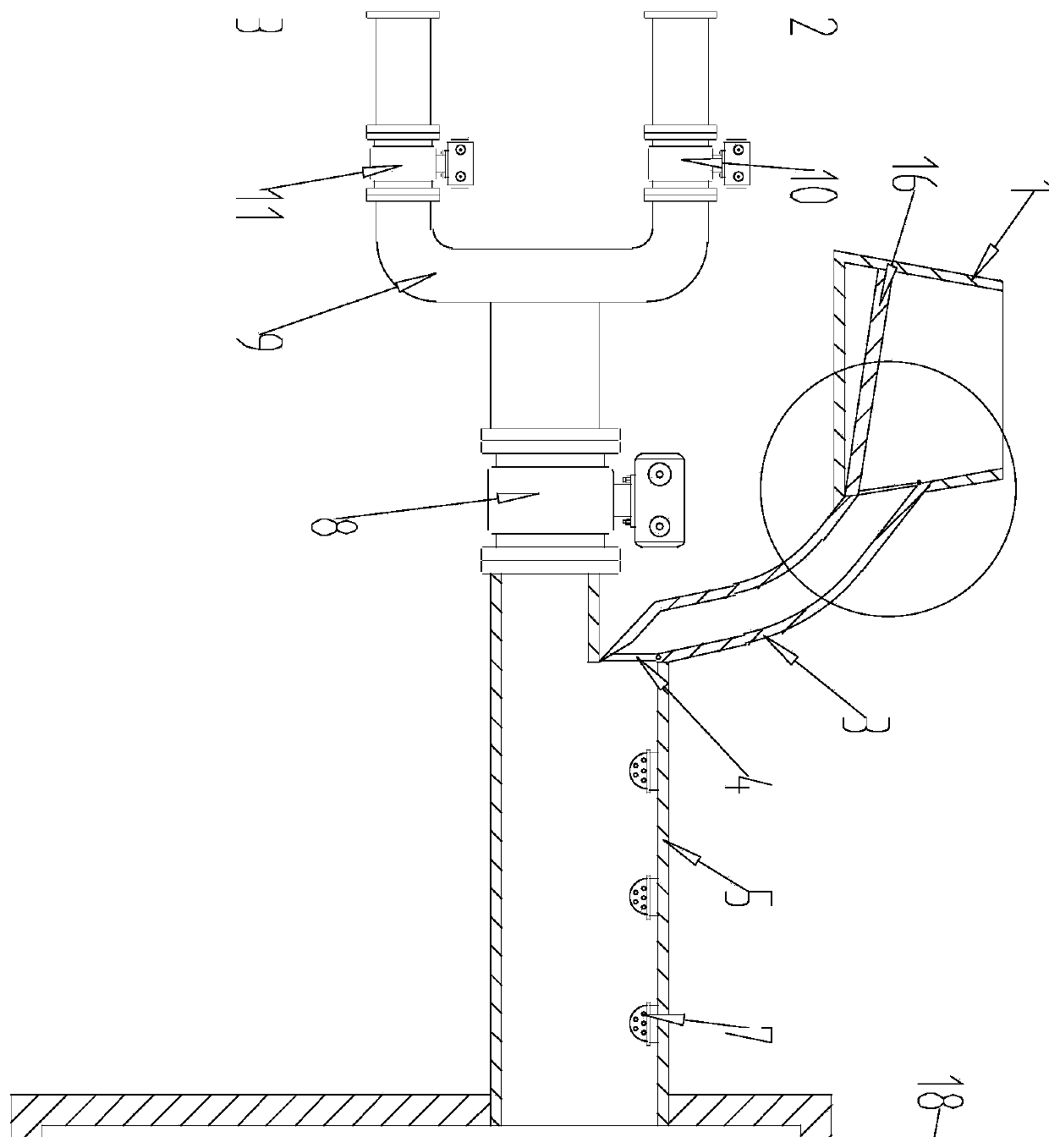

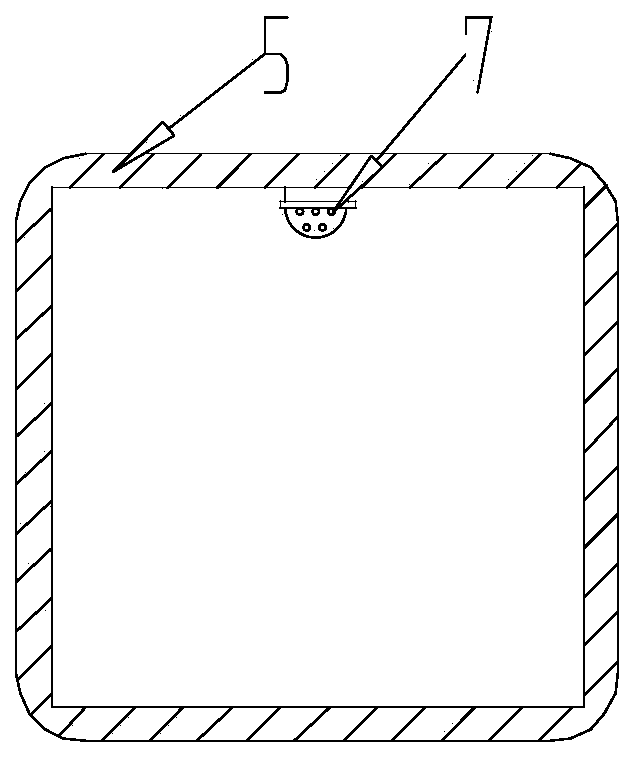

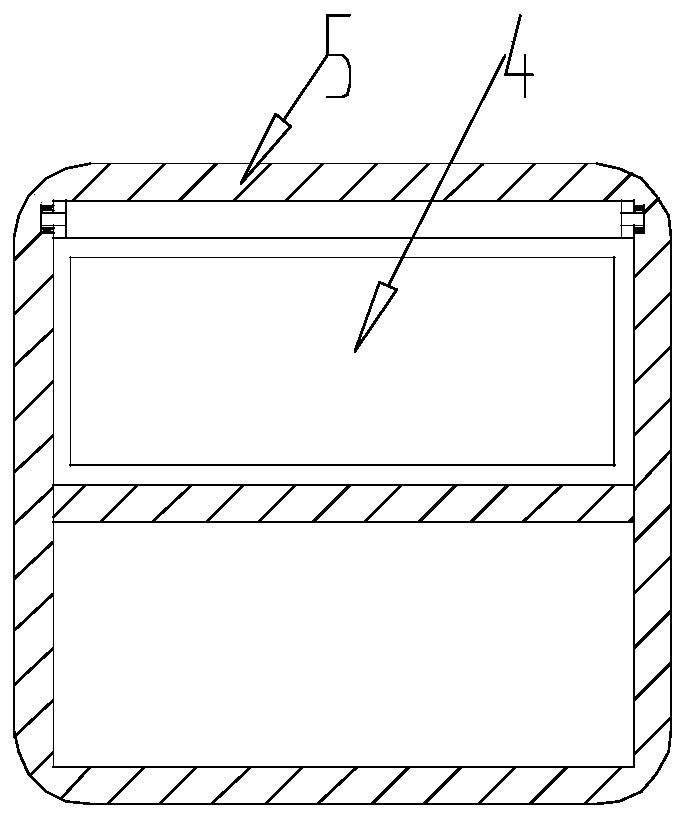

[0023] Embodiment: The coal drop hopper 1 is installed at the discharge port of the coal mill, and the pebble coal produced by the coal mill is initially collected through the coal drop hopper 1. As a preferred option, a fixed inclined plate 16 is provided inside the coal drop hopper 1 , the bottom position of the fixed sloping plate 16 and the bottom position of the coal hopper 1 are on the same horizontal plane, and the falling pebbles and coal can be gathered at the first movable baffle 2 in time and quickly. When a certain amount of pebbles and coal is exceeded, the first movable baffle 2 is pushed away, and the pebble coal falls into the coal fall pipe 3, and the pebble coal at the lower part of the coal fall pipe 3 pushes away the second movable plate, and the first movable baffle 2 and the second movable baffle 4 are both fixed at the upper part and fixed at the lower end. It is movable and has a certain weight, which can not only make the pebble coal fall quickly and sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com