Chemical vapor deposition apparatus and deposition method thereof

A chemical vapor deposition and exhaust device technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., to achieve the effect of reducing deposition, increasing distance, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

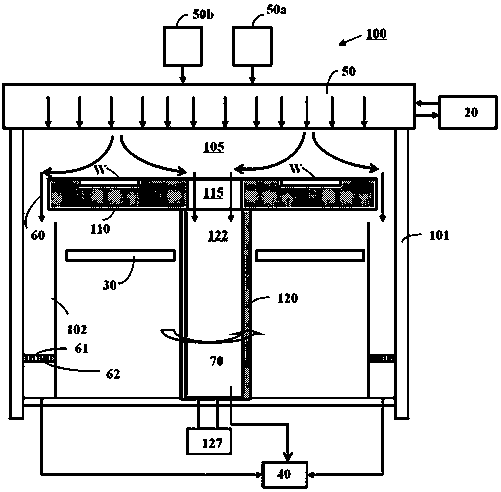

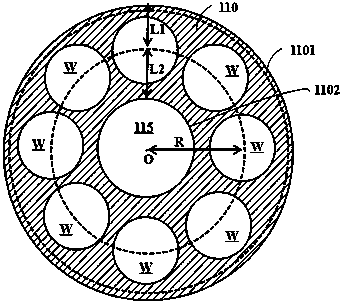

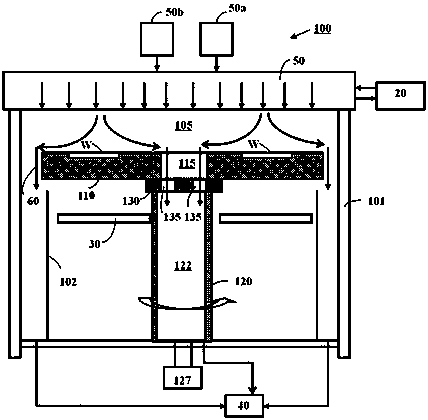

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0066] The invention provides a chemical vapor deposition reaction device and a deposition method for depositing thin films or growing epitaxial crystals on substrates or substrates. The reaction device and the deposition method can be used to deposit various thin films on the substrate or on the substrate. In particular, the reaction device of the present invention can be preferably applied to the MOCVD method or the HVPE method to deposit or epitaxially grow III-V group thin films.

[0067] The chemical vapor deposition device provided by the present invention can realize the simultaneous processing of multiple substrates in one reaction chamber, and ensure the yield and uniformity of each substrate as in a single substrate reaction chamber, thereby not only improving The yield and uniformity of deposited or epitaxially grown films can greatly increase the yield, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com