Shunting device for pipeline electrolyzer

A shunt device and electrolytic cell technology, applied in the field of electrolysis, can solve the problems of long concentration adjustment process, damage to the cell body, and inability to adjust the current independently, and achieve the effects of stable and reliable structure, large resistance, and avoiding high-temperature melt leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below by accompanying drawing.

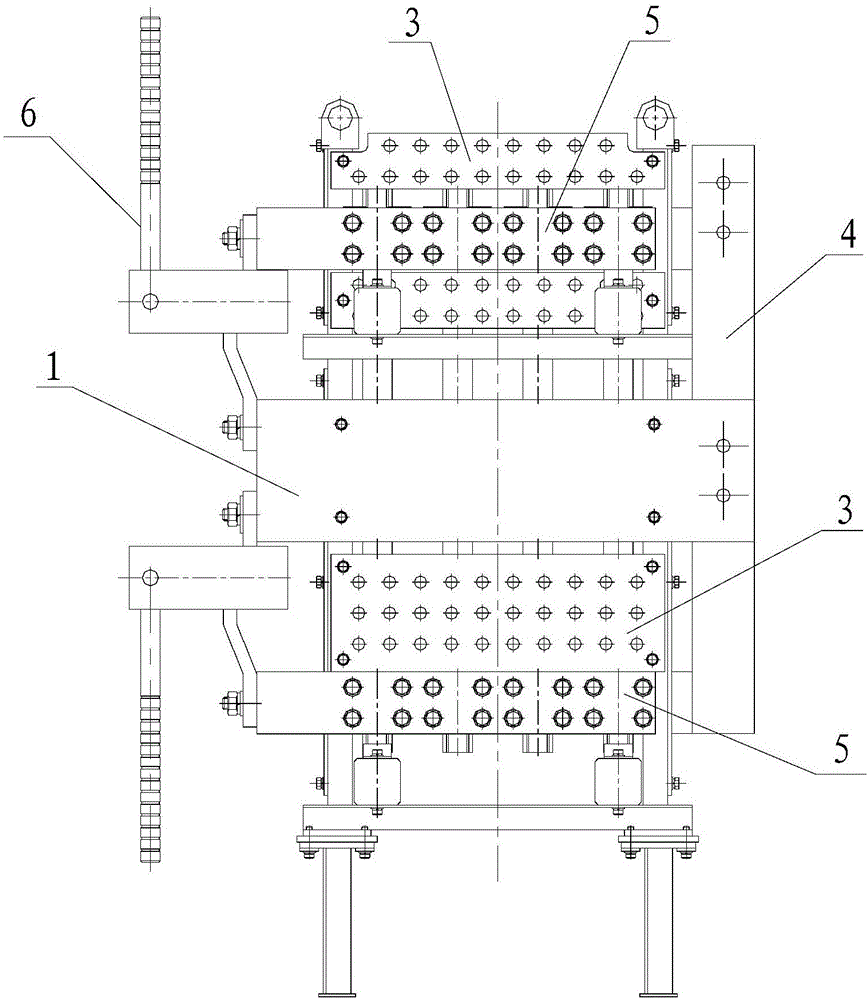

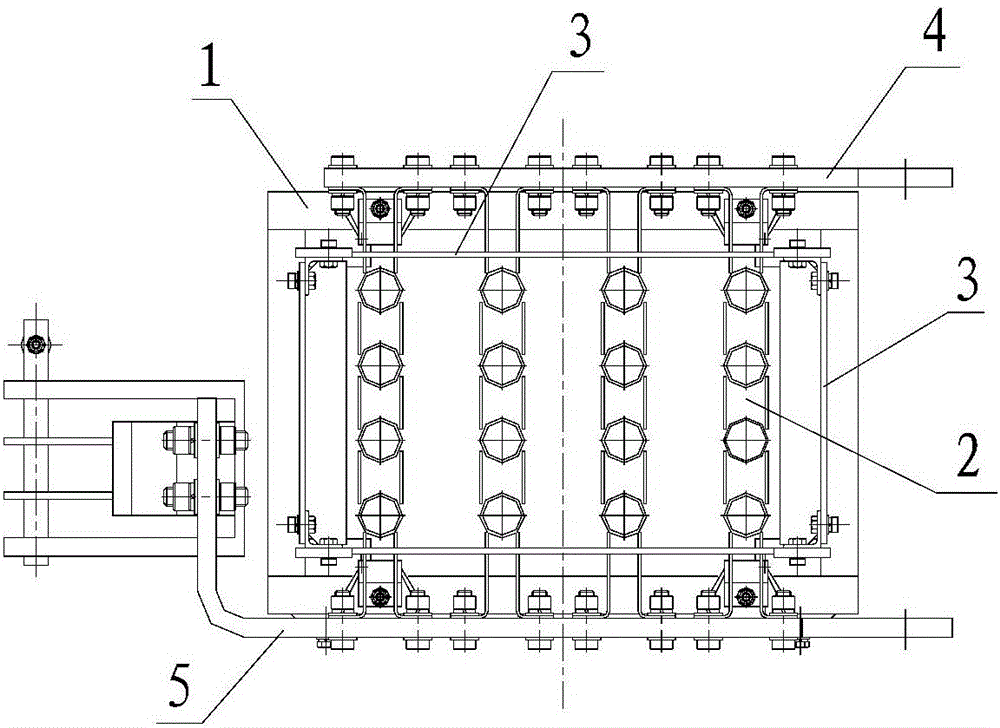

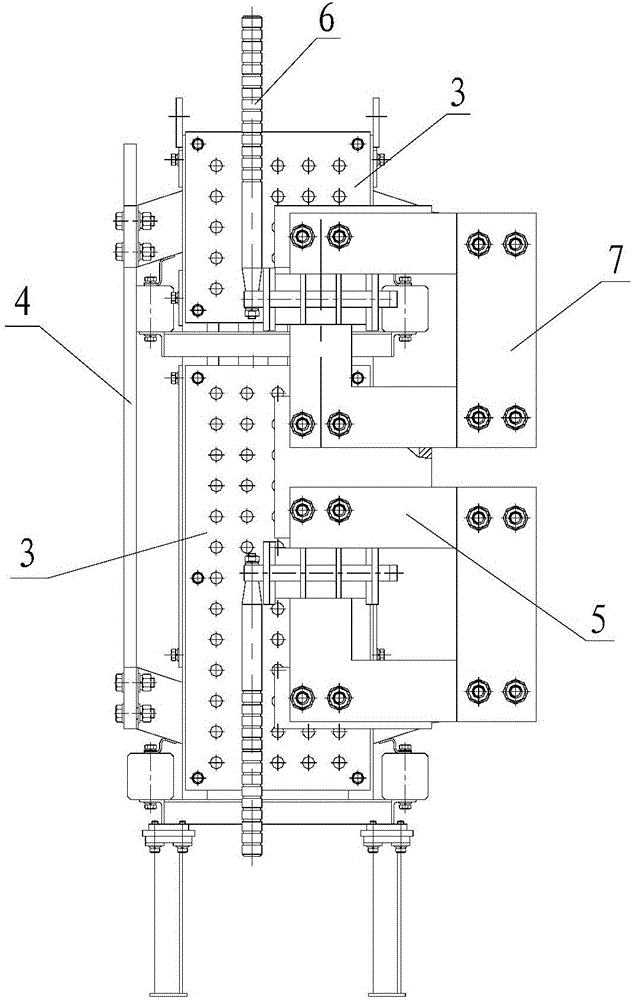

[0017] Such as figure 1 As shown, the present invention includes a plurality of shunt bodies that can be connected in series with the line electrolyzer, and the shunt body includes an installation frame 1 and a resistance assembly 2 located in the installation frame 1, and an insulating plate is arranged around the resistance assembly 2 3. One side of the installation frame 1 is provided with a busbar connection plate 4, and the other side is provided with a slot end connection plate 5. The installation frame 1 mainly plays the role of supporting, fixing and connecting the resistance assembly 2. The insulation board 3 is arranged around the resistance assembly 2. Except for the position of the installation frame 1, the rest of the parts are surrounded by the insulation board 3. In addition to the insulation function, the insulation board 3 also It can protect the resistance component 2 to a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com