Ring-spinning machine low noise high speed energy saving spindle-dual-flexible spindle

A ring spinning machine, dual-flexible technology, applied in textiles and papermaking, etc., can solve the problems of unsatisfactory structural reliability and performance indicators, complex spindle structure, high price, etc., to reduce splashing and volatilization, The effect of strong carrying capacity and extended refueling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Combine Attached drawing To further describe the implementation of the present invention, this example is used to illustrate the present invention, but does not impose any limitation on the present invention.

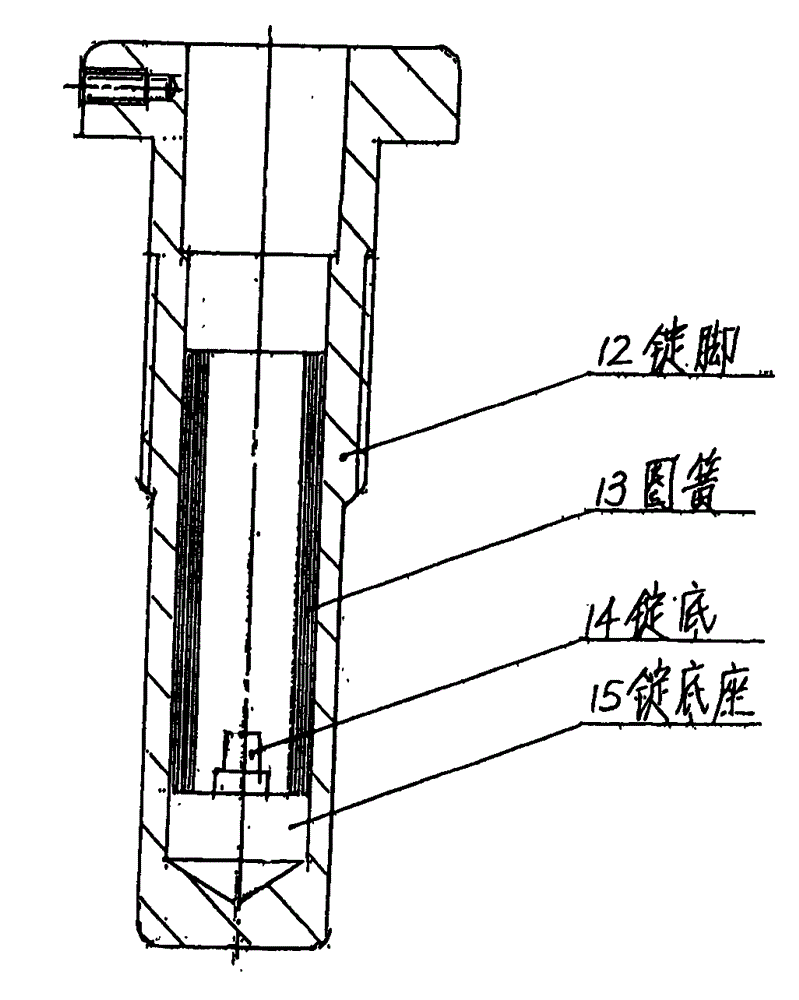

[0022] Double flexible spindle as in the abstract Figure one It is composed of high-speed rotating spindle disc and double flexible spindle foot assembly. The dual-flexible spindle component determines the characteristics of the dual-flexible spindle.

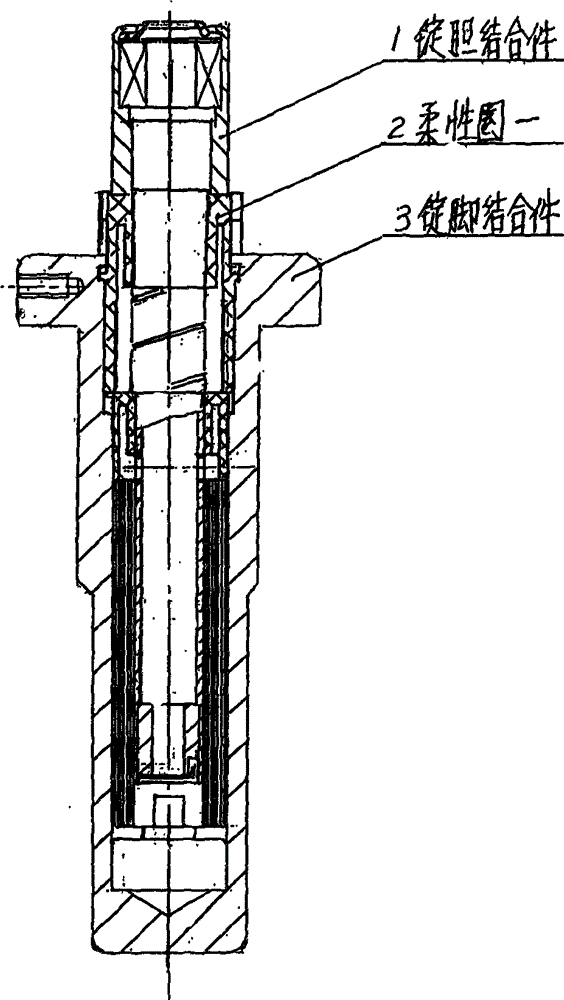

[0023] Double flexible spindle assembly ( As shown 1 ) Connect the "1" spindle joint and the "3" spindle foot joint through the "2" flexible ring one. Due to the function of the "2" flexible ring one, the upper support is flexible.

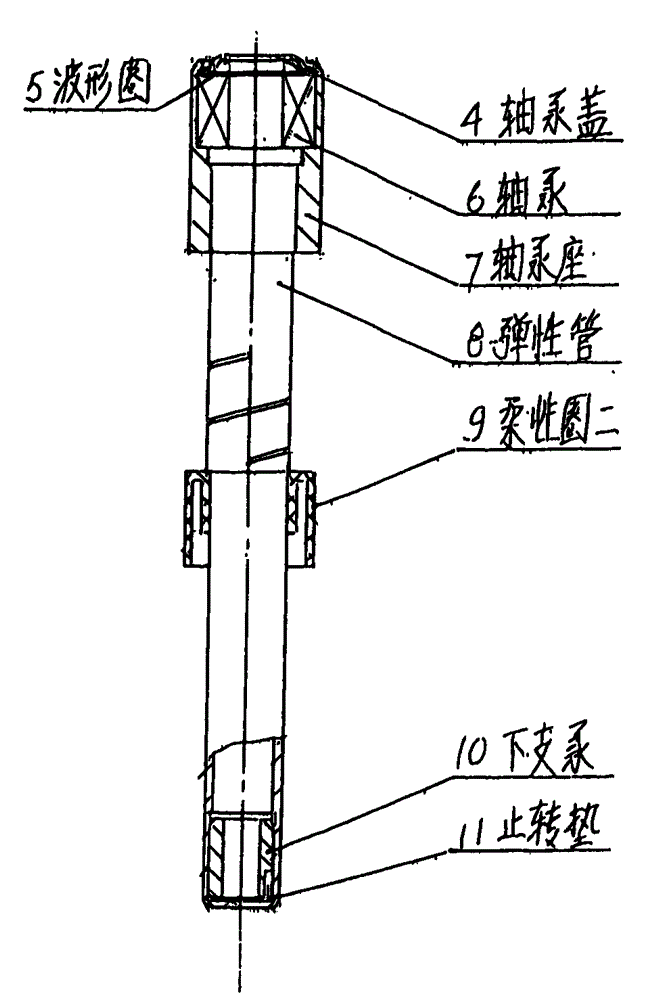

[0024] Spindles in dual flexible spindle foot assemblies Combination ( As shown 2 ), the "6" spindle bearing is pressed in the "7" bearing housing hole by the "5" wave ring with longitudinal elasticity and the "4" bearing cover, and the "8" elastic tube is tightly fitted with the "7" be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com