Slope anti-slip system

A technology of slope surface and anti-skid layer, applied in the field of slope anti-skid, can solve the problems of short service life, small size of anti-sliding pile, fracture, etc., and achieve the effect of long service life, good anti-skid effect and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

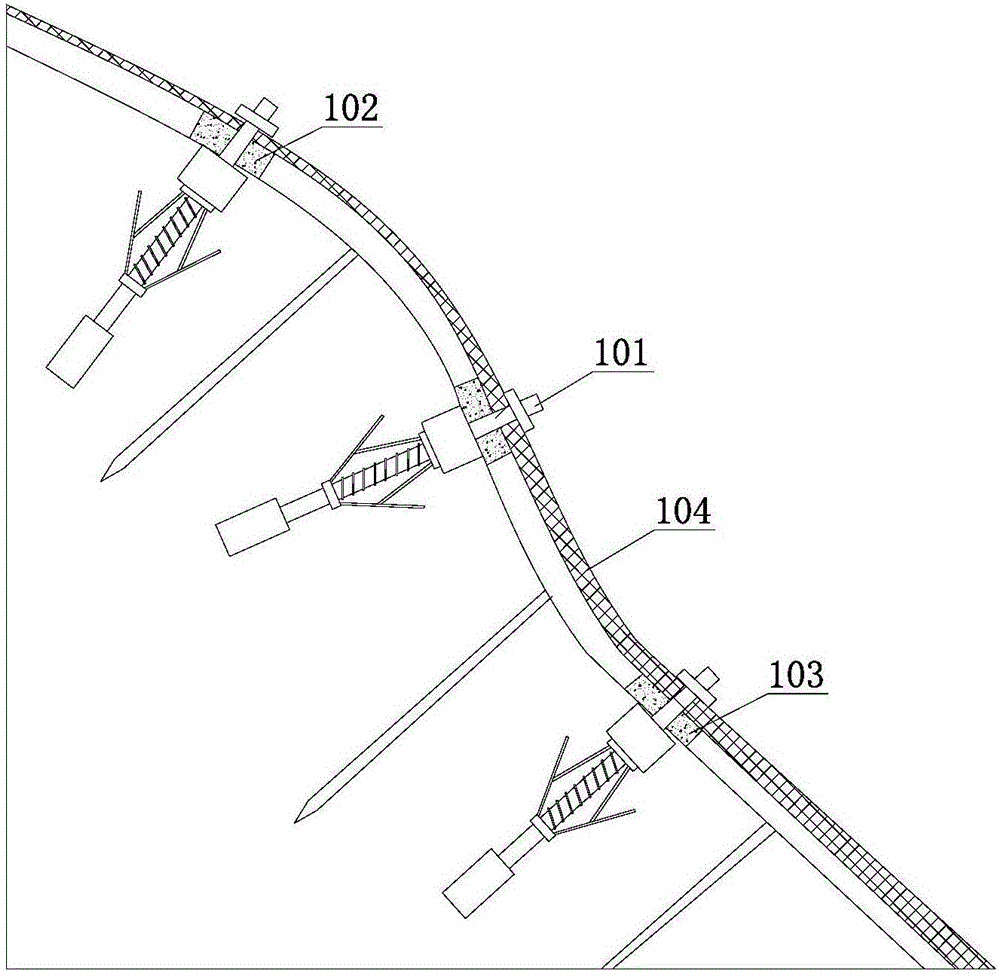

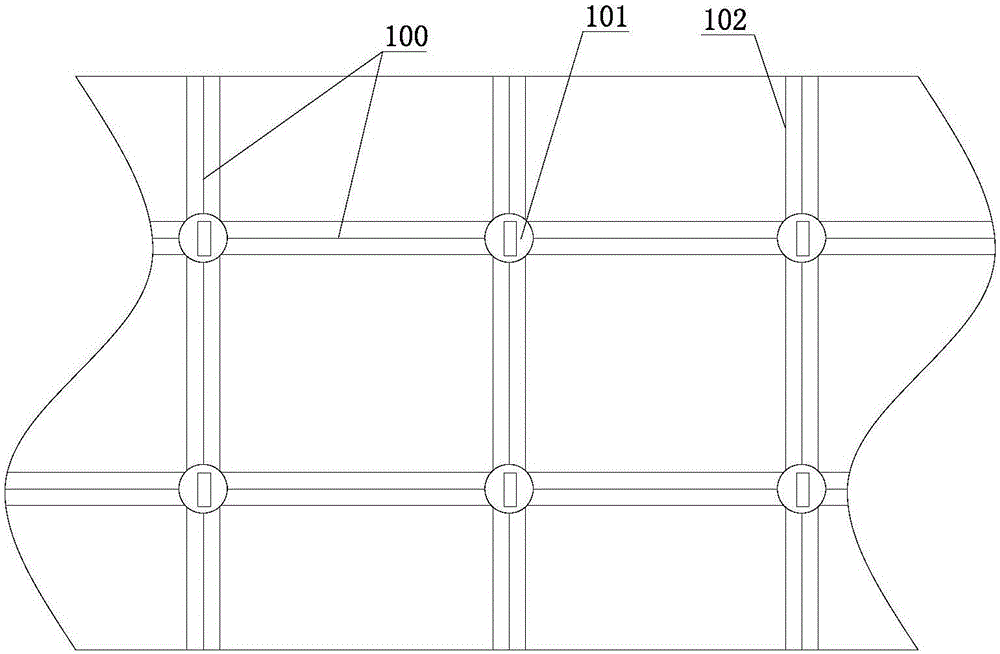

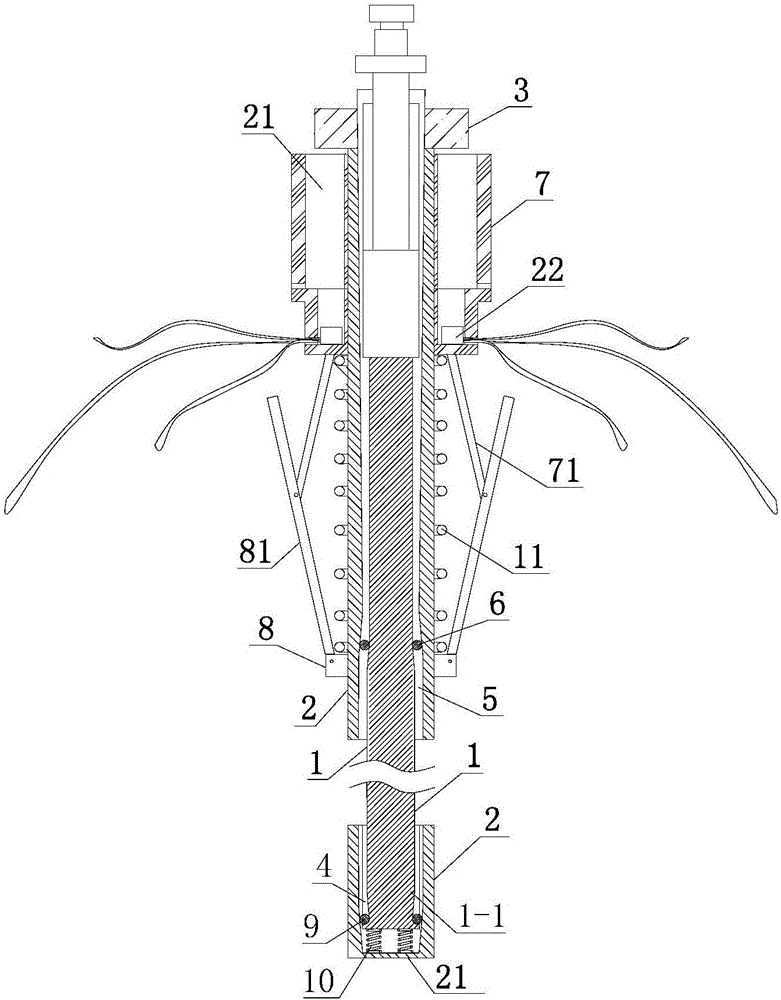

[0026] Such as Figure 1-7 As shown, a slope anti-skid system includes an anchor cable 100, an anchor unit 101, and a slope fixing layer 102 distributed along the slope. There are more than one anchor unit 101, and the specific number can be set as required. The anchoring units 101 are arranged longitudinally along the slope fixing layer 102 , and the anchor cables 100 are tensioned to connect adjacent anchoring units 101 , and each anchoring unit 101 includes an anchor rod 1 , an outer casing 2 and a tightening member 3 .

[0027] Specifically, the outer sleeve 2 is sleeved outside the anchor rod 1, and the outer sleeve 2 is used to be deeply buried in the slope soil, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com