A method for converting o-cell test pile load into vertical compression pile load

A vertical and test pile technology, which can be used in basic structure testing, construction, infrastructure engineering and other directions, and can solve problems such as low bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

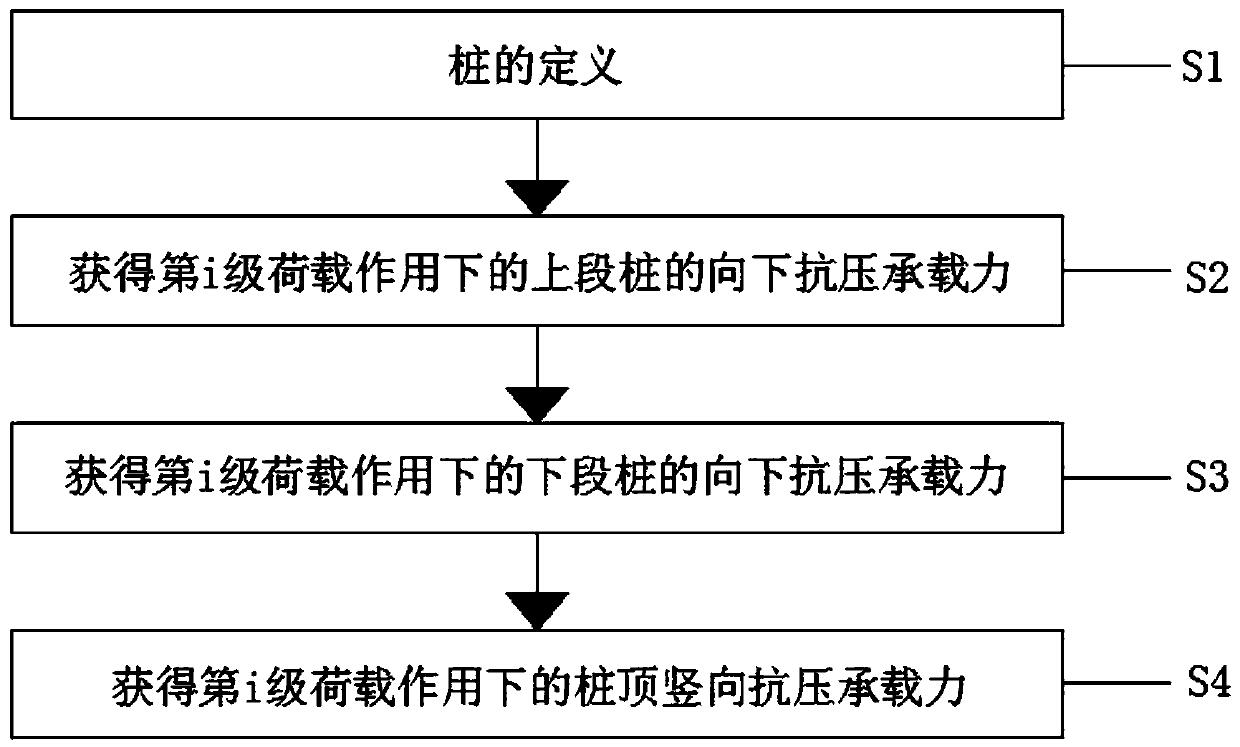

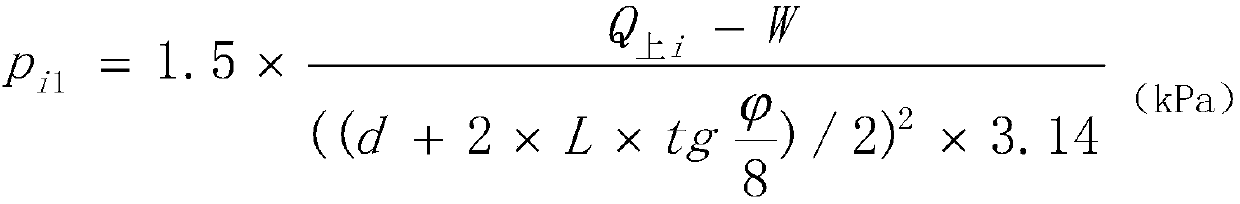

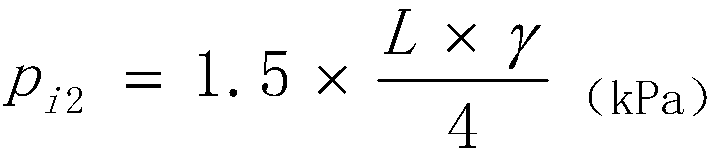

[0037] A method of converting O-cell test pile load into vertical compression pile load:

[0038] 1. The pile body used is l / d=30, the diameter of the pile is 500mm, the length of the pile is 15m, and the weight of the pile body is 70.7kN, acting on cohesive soil, so λ 上 = 1.25, the internal friction angle of the soil around the pile is 15°, and the end resistance of the soil at the pile end is 2000kPa.

[0039]2. The carrying capacity conversion data according to this method are shown in Table 1-1 below:

[0040] Table 1-1

[0041]

[0042] 3. Comparative experiment:

[0043] The load converted by the O-cell method, the converted load obtained in Example 1, and the vertical compressive load on the top of the pile obtained by the traditional method were compared (the same pile body as in Example 1 was selected).

[0044] The load converted by the O-cell method, the conversion obtained in Example 1 and the comparison of the vertical compressive load on the top of the pile...

Embodiment 2

[0049] A method of converting O-cell test pile load into vertical compression pile load:

[0050] 1. The pile body l / d=60, the diameter of the pile is 500mm, the length of the pile is 30m, and the weight of the pile body is 141.3kN, acting on cohesive soil, so λ 上 = 1.25, the internal friction angle of the soil around the pile is 15°, and the end resistance of the soil at the pile end is 2200kPa.

[0051] 2. The bearing capacity conversion data according to this method are shown in Table 2-1 below:

[0052] Table 2-1

[0053]

[0054] 3. Comparative experiment:

[0055] The load converted by the O-cell method, the converted load obtained in Example 2, and the vertical compressive load on the top of the pile obtained by the traditional method were compared (the same pile body as in Example 2 was selected).

[0056] The load converted by the O-cell method, the comparison between the converted load obtained in Example 2 and the vertical compressive load on the top of the pi...

Embodiment 3

[0061] A method of converting O-cell test pile load into vertical compression pile load:

[0062] 1. The pile body used is l / d=90, the diameter of the pile is 500mm, the length of the upper section of the pile is 45m, and the weight of the upper section of the pile is 212.0kN, acting on cohesive soil, so λ 上 = 1.25, the internal friction angle of the soil around the pile is 15°, and the end resistance of the soil at the pile end is 2500kPa.

[0063] 2. The bearing capacity conversion data according to this method are shown in Table 3-1 below:

[0064] Table 3-1

[0065]

[0066] 3. Comparative experiment:

[0067] The load converted by the O-cell method, the converted load obtained in Example 3, and the vertical compressive load on the top of the pile obtained by the traditional method were compared (the same pile body as in Example 3 was selected).

[0068] The load converted by the O-cell method, and the comparison between the converted load obtained in Example 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com