Construction method of cylindrical self-sinking underground space structure

A construction method and technology of spatial structure, applied in underwater structures, infrastructure engineering, caisson and other directions, can solve the problems of surrounding environmental pollution, many construction procedures, and large construction noise, and achieve the reduction of procedures, contact area, and The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

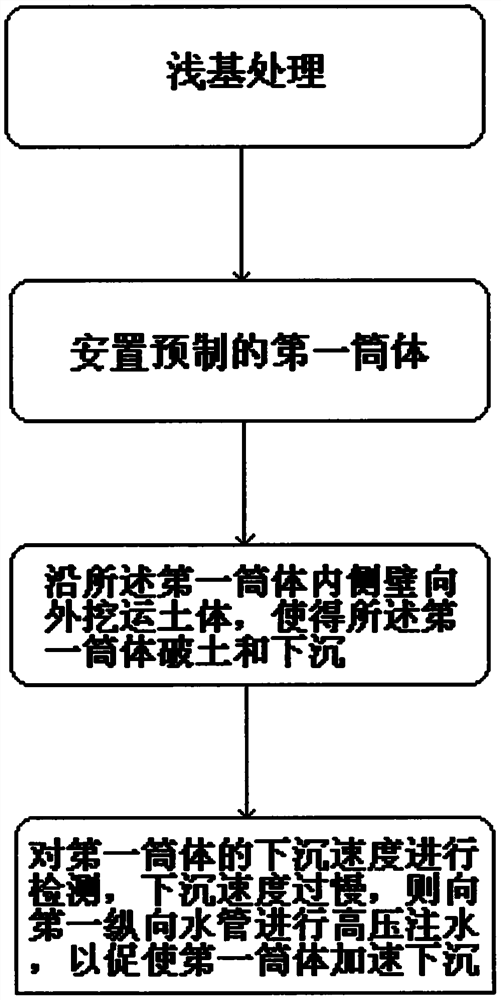

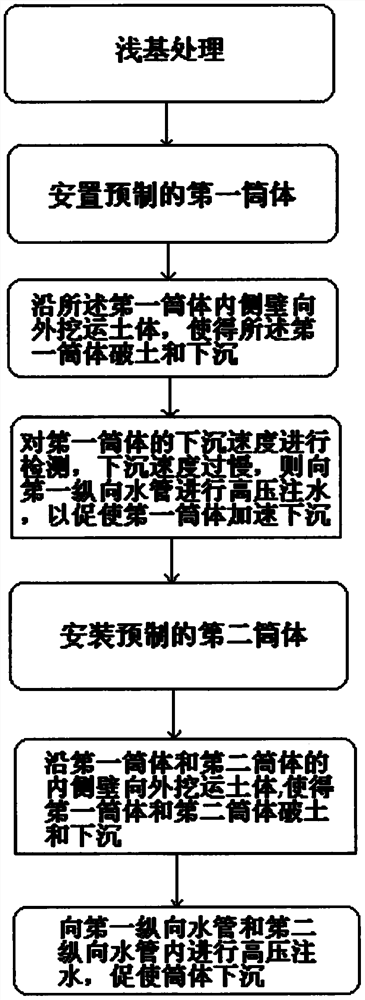

[0034] Such as figure 1 As shown, the invention discloses a construction method of a cylindrical self-sinking underground space structure, comprising the following steps:

[0035] a. Shallow foundation treatment;

[0036] b. longitudinally place the prefabricated first cylinder body 1 in place;

[0037] c. Excavating soil from the inside of the first cylinder and along the inner wall of the first cylinder, so that the first cylinder achieves soil breaking and subsidence through the cooperation of the soil breaking structure and its gravity;

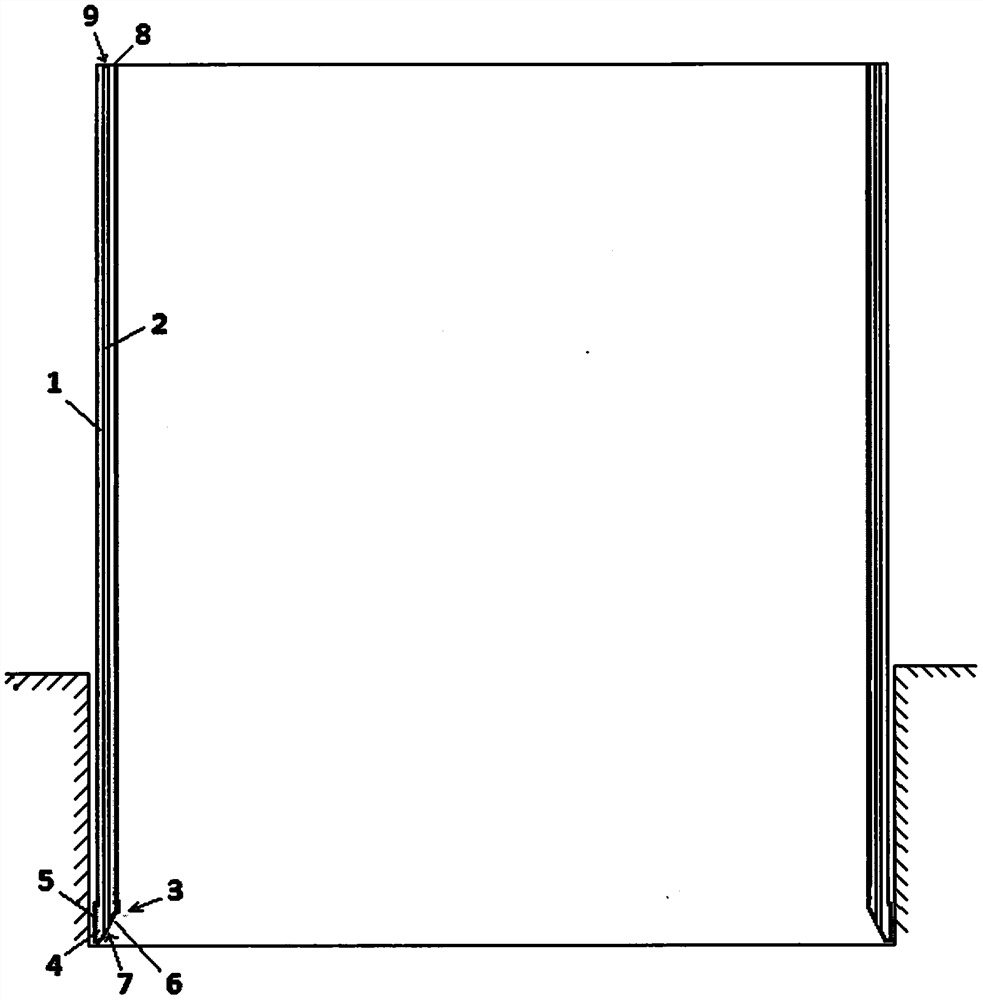

[0038] Among them, such as figure 2As shown, a first longitudinal water pipe 2 is installed in the first cylinder body 1, and the bottom of the first cylinder body 1 is provided with or formed with a ground-breaking structure 3; wherein, the ground-breaking structure 3 has a hypotenuse inside and The cross-section is a blade foot structure with a large top and a small bottom, wherein the ground-breaking structure 3 has a protruding st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com