Connecting member

A technology of connectors and plug-ins, which is applied in the field of mechanical components, can solve the problems of brittle failure of welds, and achieve the effects of easy maintenance and replacement of components, avoiding accidental errors, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

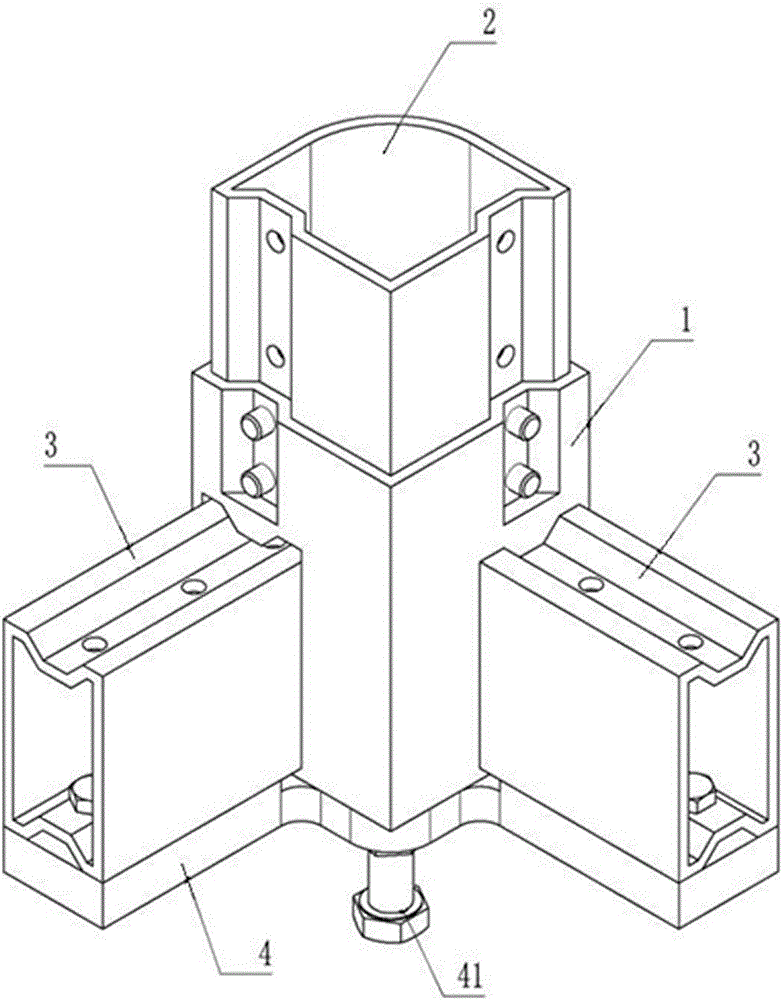

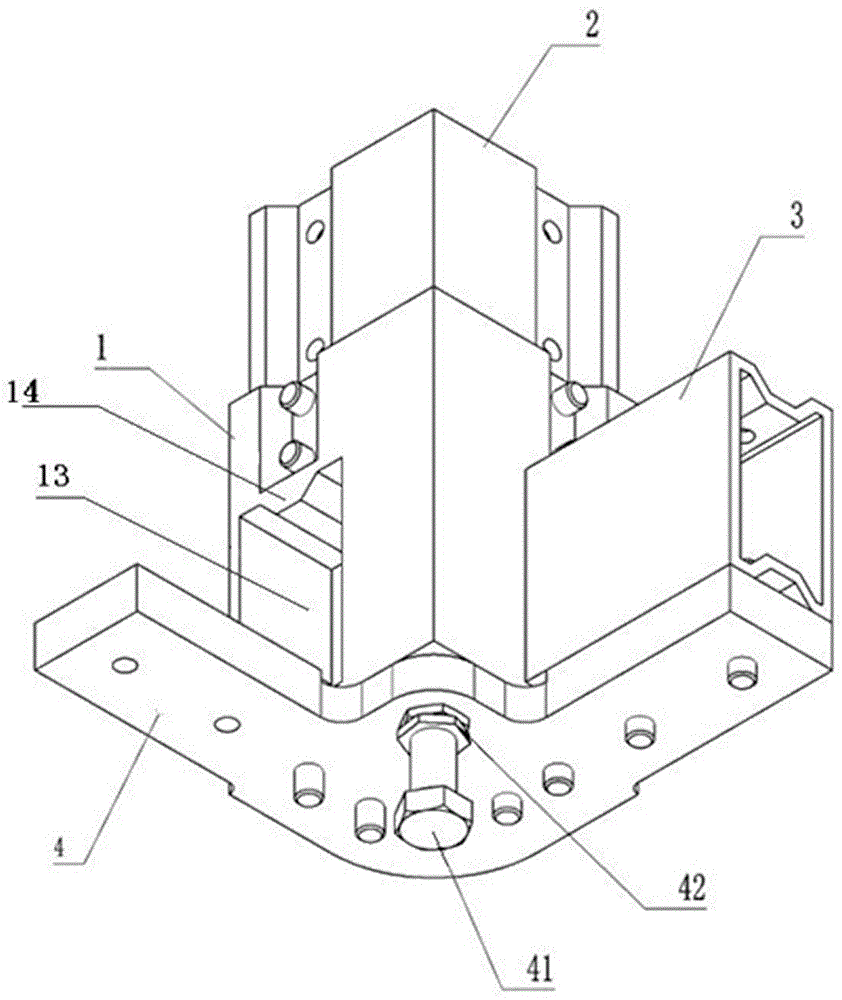

[0023] A connecting piece includes a base 1 , a straight insert 2 , a side insert 3 and a fixing plate 4 . The top of the base 1 is provided with a first recess 18, and the side of the base 1 is provided with a second recess 13, and the second recess 13 is two, respectively located on two opposite sides of the base 1. Proximal side. The cross-section of the base is fan-shaped, and the base is provided with two sides perpendicular to each other (such as figure 2 shown).

[0024] The first protrusion 11 is provided on the side of the first recess 18 , and the number of the first protrusions 11 is two, respectively located on two sides of the first recess 18 .

[0025] The second recess 13 is provided with second protrusions 14 , and the number of the second protrusions 14 is two, respectively located on the bottom surface of the base 1 and its corresponding surface.

[0026] The shape of the first protrusion 11 and the second protrusion 14 is an isosceles trapezoid. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com