Installing construction process of ceiling clean plate

A construction technology and clean technology, which is applied in the field of installation and construction technology of ceiling clean panels, to achieve the effects of improving construction quality and construction efficiency, ensuring accuracy, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

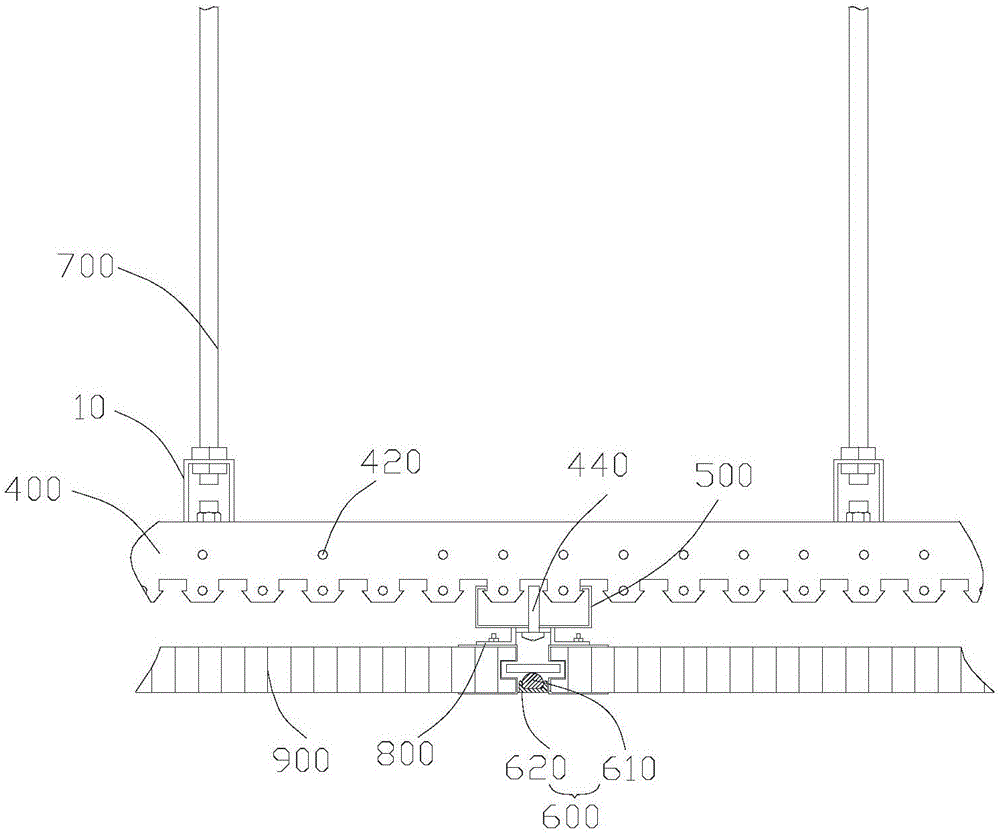

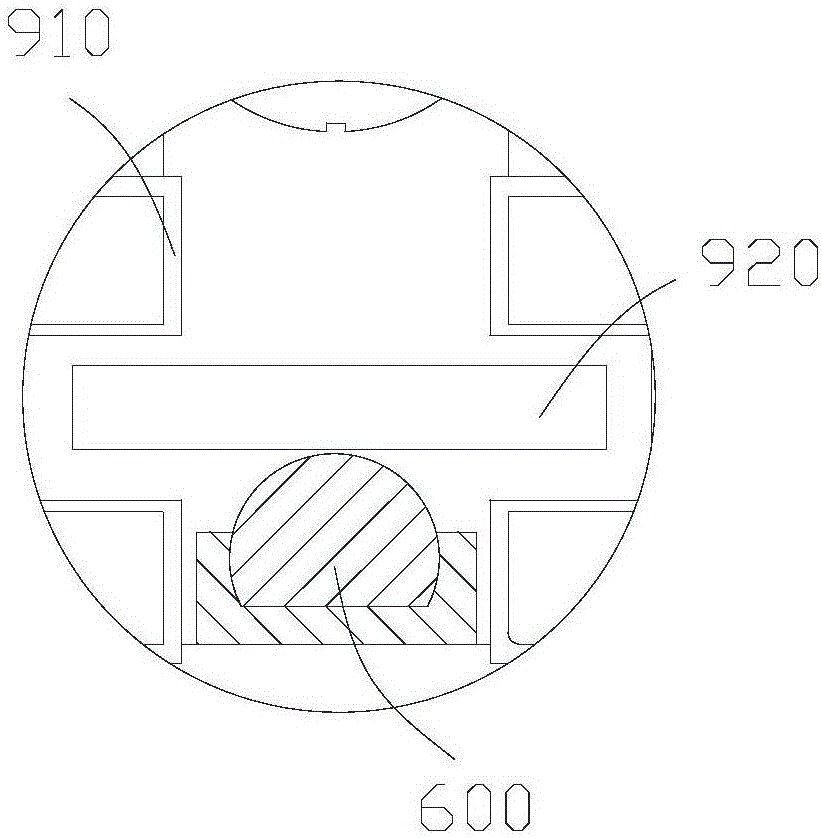

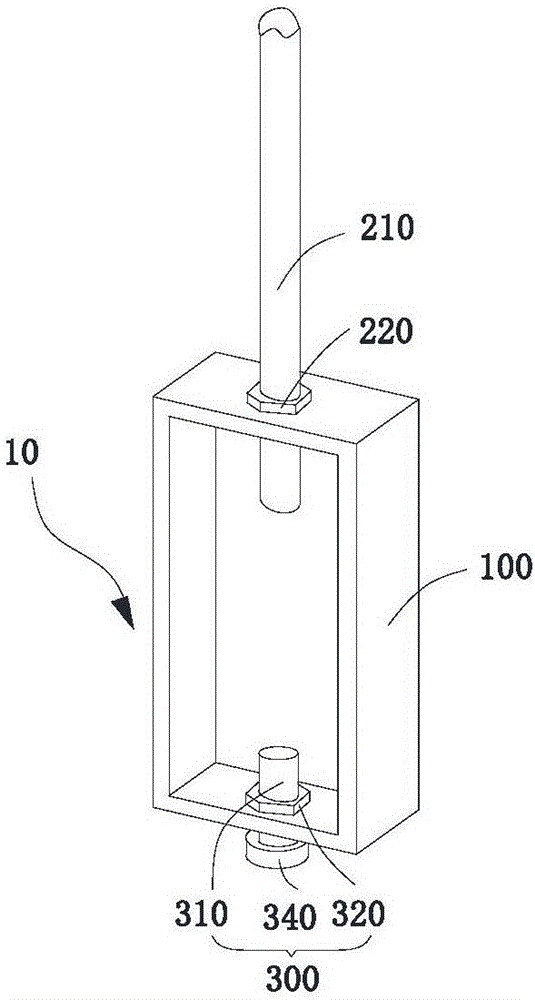

[0056] see Figure 1-Figure 2 , figure 1 It shows the structure diagram of the suspended ceiling clean panel 900 after installation. This embodiment provides a construction process for installing the ceiling clean panel 900, which is used for the installation of the ceiling clean panel 900 in the aviation factory building, and meets the use requirements of the aviation factory building. The construction process includes the following steps:

[0057] Step S100, determining the position of the hanging point on the floor. When carrying out the ceiling of the floor slab in the factory building, first check to confirm that the roof waterproofing has been completed and has passed the acceptance test, and the layout of the partition wall and the plastering construction have been completed. According to the design requirements, the span of the room, and the actual situation on site, determine the number of hanging points and embedded parts, and calculate the required main keel 400....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com