A locking device for urban rail vehicles and bus door systems

A technology for public transport vehicles and urban rails, which is applied to electric locks, power transmission/actuator features, etc., and can solve problems such as difficulty in replacement, damage to locking device parts, and failure to consider the meshing fit of the end toothed disc and the end toothed shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

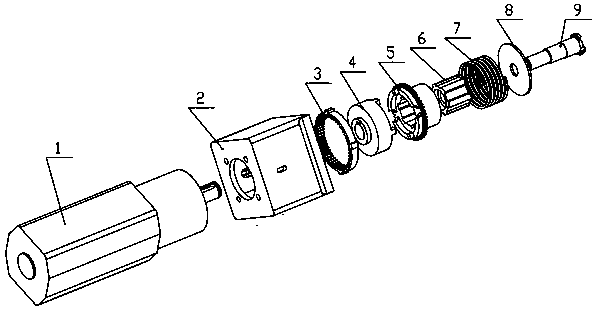

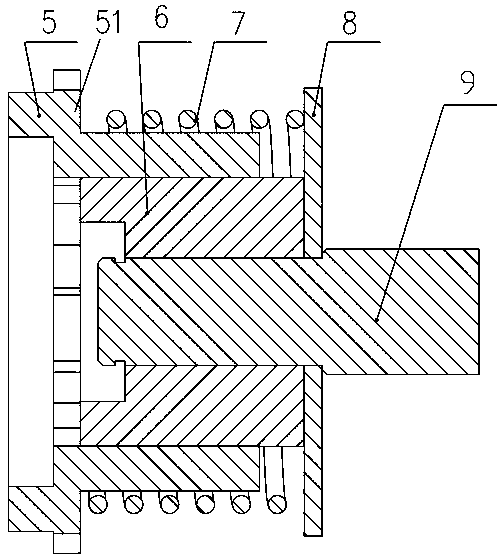

[0024] Such as figure 1 , 2 , 3, and 6, a locking device for urban rail vehicles and bus door systems mainly includes a driving part and a driven part. In the figure, 1 is a motor, 2 is a connecting sleeve, 3 is an internal gear, and 4 Be a sleeve, 5 is an external gear, 6 is a spline sleeve, 7 is a spring, 8 is a baffle plate, and 9 is a screw mandrel.

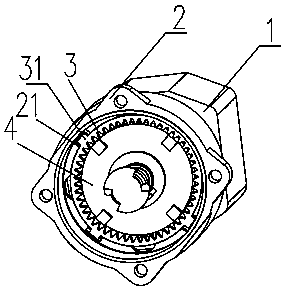

[0025] active part as figure 2 As shown, it includes a motor 1, a connecting sleeve 2, an internal gear 3, and a sleeve 4.

[0026] The motor 1 is rigidly connected to the connecting sleeve 2 , and the shaft 11 of the motor 1 is connected to the sleeve 4 through a key 41 .

[0027] A groove 21 is arranged in the inner cavity of the connecting sleeve 2 along the circumference, and a protrusion 31 is correspondingly arranged on the internal gear 3 . Since the internal gear 3 is embedded in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com