A downhole restrictor

A technology of chokes and choke parts, which is applied in the direction of mining fluids, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of inconvenient use and high cost, achieve convenient use, reduce the formation of hydrates, and improve development efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

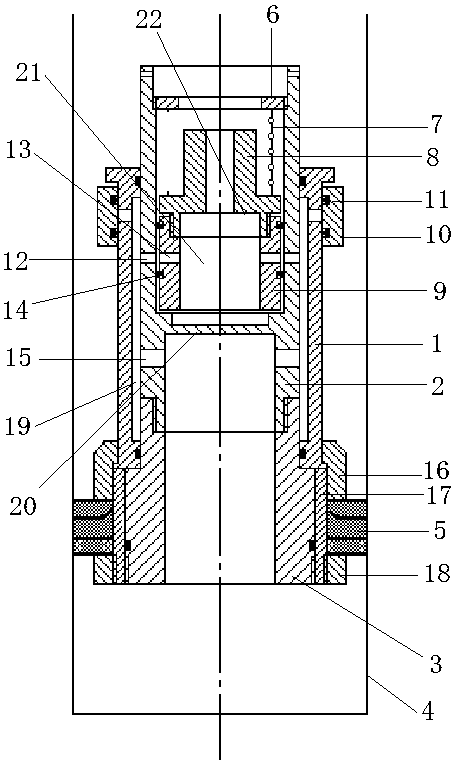

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. A specific embodiment of a downhole choke of the present invention, such as figure 1 As shown, it includes an outer jacket 1, an upper central tube 2 arranged in the outer jacket 1, a lower central tube 4, a piston 9 arranged in the upper central tube 2, and an air nozzle 8, and the air nozzle 8 forms an air outlet, a sealing mechanism 5, an upper stop Ring 16, lower retaining ring 18, rubber sleeve 17 and drain sleeve 11, the upper and lower central tubes and outer casing 1 form the shell, the piston 9 forms a floating throttling member, and the air nozzle 8 is arranged on the piston 9 and then passes through the The spring device in the upper central pipe 2 is floating up and down and assembled in the upper central pipe 2, the lower end of the upper central pipe 2 and the upper end of the lower central pipe 3 are threadedly connected to form a central pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com